SAFE-T product family transforms contamination control

World’s-first battery-powered cleanroom floor cleaning range?

i-team Global unveils the SAFE-T product family, said to be the world’s first battery-powered cleanroom floor cleaning range. These innovations help businesses keep contamination out of critical environments while saving time, reducing costs, and addressing staff shortages.

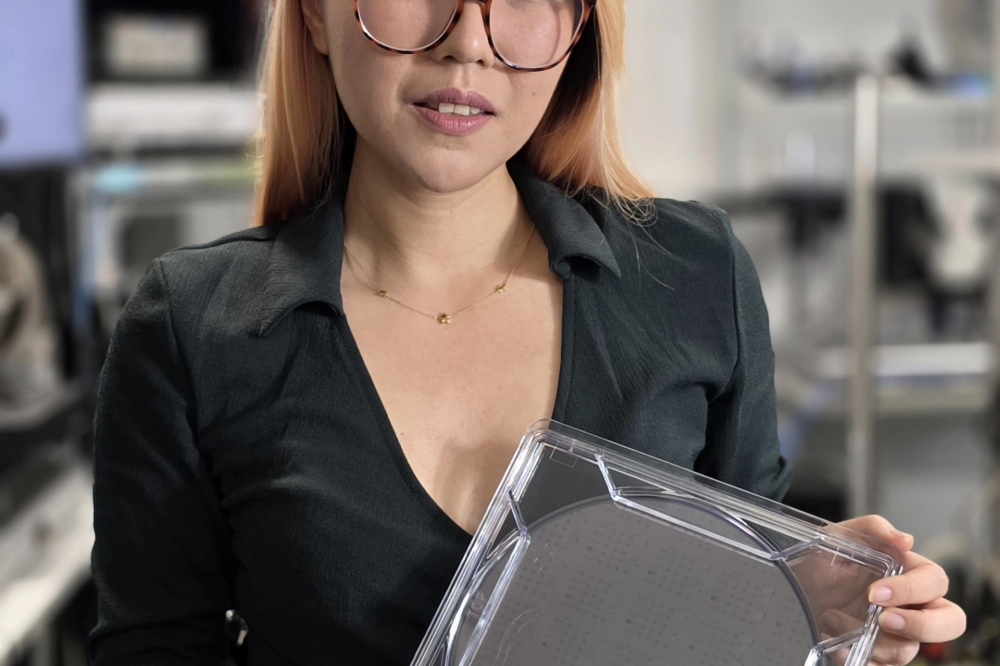

Combining stringent floor cleaning ability, ergonomic design and efficient battery systems, these trailblazers transform controlled environments. Industry sectors such as high-tech, semiconductors, medical devices, healthcare, pharmaceuticals, and food production can now meet the required cleanliness standards with less effort.

Activate SAFE-T Superpowers

Traditional cleanroom floor cleaning relies heavily on manual wiping and mopping, which is time-consuming and inconsistent. With powerful mechanical scrubbing and Ultra-Low Particulate Air (ULPA 15) filtration, SAFE-T removes more embedded particles than manual methods, capturing over 99.999% of contaminants as small as 0.1 microns.

Reduce downtime and operational costs

When contamination issues occur, production temporarily comes to a halt. The quicker the cleaning is done, the sooner production can resume. Cleaning teams play a vital role in minimizing downtime costs by following strict protocols. With staff shortages becoming a challenge, smarter processes help ease their workload. These tools are intuitive, easy to use, and require minimal training to get started.

In an already challenging environment, the SAFE-T range is designed to make cleaning easier and reduce physical strain on operators. No more dealing with floor cables or searching for a power socket. Lightweight machines with ergonomic features and intuitive controls improve both comfort and efficiency. These sustainable products also eliminate single-use mop waste, as well as water and chemical usage.

Meet the guardians of the cleanroom

Each solution is designed specifically for cleanroom settings and the exhaust output is certified to the rigorous ISO standards for these controlled environments:

• SAFE-T-IMOP, a vertical scrubber dryer for cleanrooms and sticky mats: ISO 5-6

• SAFE-T-VAC, a cordless vacuum cleaner: ISO 4-5

• SAFE-T-BOT 45, a robotic scrubber dryer: ISO 5

Frank van de Ven, founder and CEO of i-team Global, says, “We are proud to lead the way as the first company to offer the only suite of automated cleaning solutions specifically designed for cleanrooms. Cleanroom cleaning companies play a vital role in minimising downtime. Now we are providing them with superpowers to tackle contamination with efficiency and precision, reducing downtime and saving significant costs.”