Ensuring gas purity for complex semiconductor manufacturing

As demand for chips grows, the semiconductor industry is pushing the limits of current manufacturing capabilities. Companies that invest in cutting-edge QA/QC tools will not only keep pace with demand, but also gain a competitive advantage in a fiercely competitive global market.

By Daniel Merriman, semiconductor consultant at Thermo Fisher Scientific

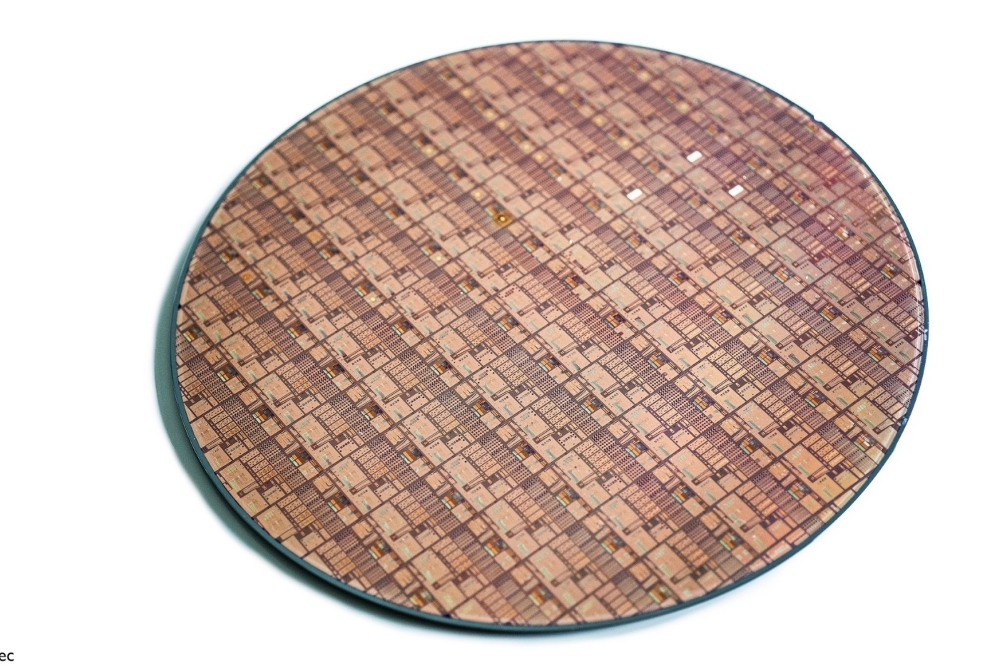

Semiconductor chips are the driving force behind modern electronics. Any electronic device – from the cell phone in your pocket to the LED lights in your home or office – uses semiconductor technology, and many of these devices are becoming smarter and more connected with each iteration. There’s expanding use of advanced semiconductor technology across a wide range of applications, such as artificial intelligence (AI), wearable technology and advanced data centers. In fact, Deloitte projected that the industry is on track to reach $1 trillion in chip sales by 2030, largely driven by the demand for generative AI.

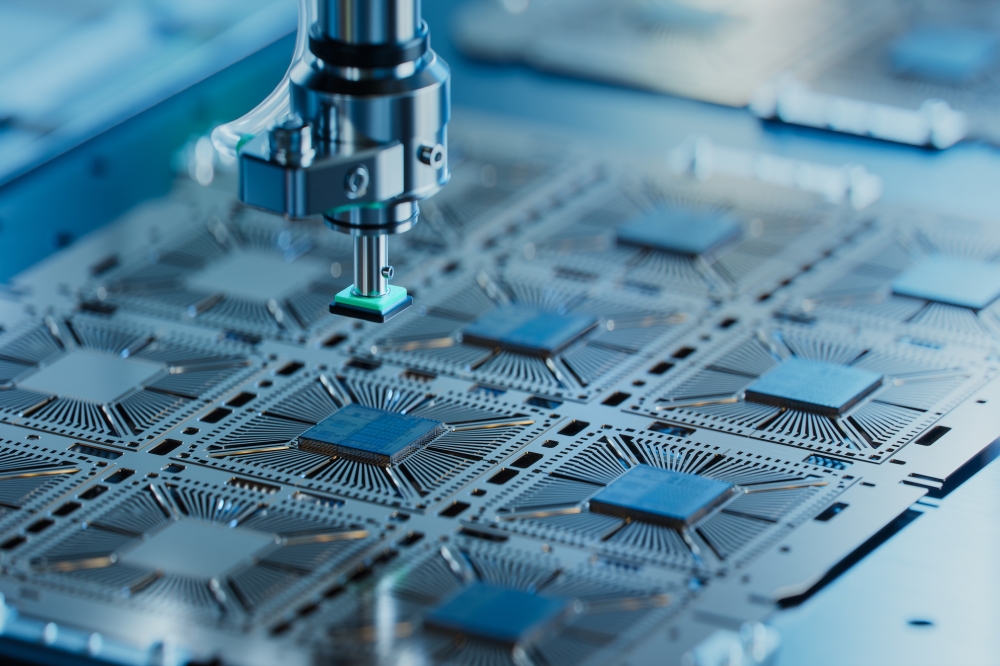

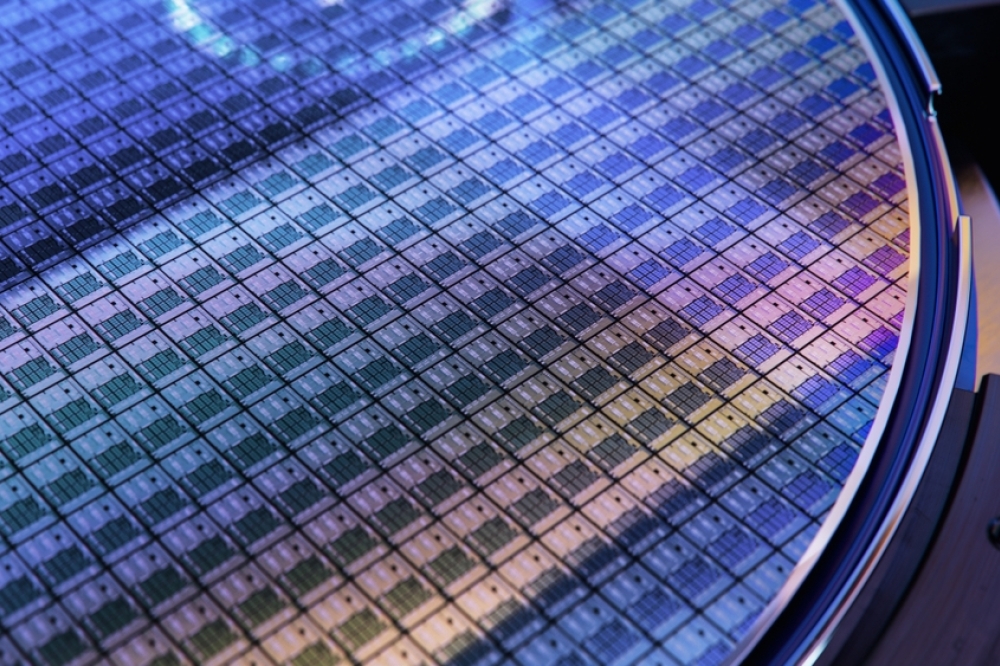

As the global semiconductor industry grows to an estimated $1 trillion by 2030 and semiconductor manufacturers transition to advanced, three-dimensional chip designs that support society’s technological advancement, there’s a critical need for a consistent supply of ultra-high purity (UHP) gases during production. Gas impurities can result in poor device performance, production delays and revenue loss. While tools like electron microscopes can help identify micro-scale physical defects that impact production, innovative analytical technologies, such as UHP electronic gas analyzers that combine atmospheric pressure ionization mass spectrometry (API-MS), can help ensure that semiconductor manufacturers have the UHP gases they need to achieve the precision required for these semiconductors.

API-MS sets a new benchmark in gas analysis by enabling the continuous detection of impurities at exceptionally low levels. This sensitivity ensures even the tiniest contaminants are identified, addressing the industry’s need for extreme

precision for manufacturers. The industry needs next-generation gas analyzers to streamline and optimize quality control (QC) processes to meet

he stringent demands of semiconductor manufacturing.

Challenges in quality control for semiconductor manufacturing

Challenges in quality control remain even with the most advanced semiconductor production processes. Because chips are susceptible to impurities, which can absorb through the surface of the wafer and affect the properties of subsequent layers, even trace levels of contaminants in the gas supply can result in costly defects, production delays and revenue loss.

To maintain wafer integrity, semiconductor manufacturers need tools for greater precision in electronic specialty gas (ESG) composition, which includes nitrogen, oxygen, argon, hydrogen, helium and carbon dioxide, among others. UHP gas analyzers allow each bulk gas to be monitored for a range of potential contaminants at parts per trillion (ppt) level detection, which meets the most stringent quality requirements.

Historically, techniques such as gas chromatography and thermal desorption have been used to monitor the purity of ESGs. However, as industry focuses on producing smaller, more complex chips, these methods become inadequate for industry demands, where contamination limits must be far lower and more precise. When impurities go undetected in manufacturing, it can result in scrapped wafers, wasted resources and production line suspensions. The financial and reputational stakes are higher than ever in a growing industry under pressure to deliver flawless devices.

Adopting API-MS into workflow for QC

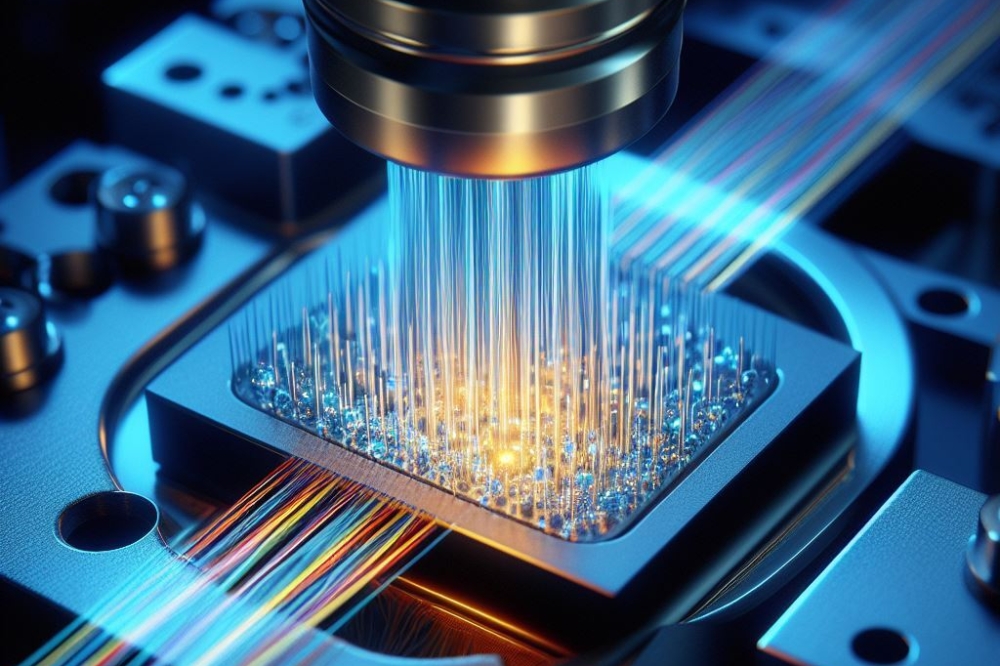

For continuous impurity monitoring, manufacturers should look to adopt innovative analytical technologies, such as API-MS analyzers. When coupled with sophisticated electronics and software, API-MS analyzers can help overcome the limitations of technologies like gas chromatography.

With real-time feedback, manufacturers are able to quickly address quality issues and avoid costly disruptions. API-MS analyzers can also detect a wider spectrum of impurities, such as combining oxygen and moisture with hydrocarbons, hydrogen, carbon monoxide and inert gases. This information ensures manufacturers can confidently meet evolving standards for gas purity.

Another benefit of adopting API-MS analyzers is that the technology can reduce capital and operational costs by providing multi-component and multi-stream solutions. These analyzers have built-in automated calibration capability which further reduces user intervention and drives down cost of ownership. To ensure that complex semiconductor manufacturing is optimized for maximum yield, gas manufacturers and semiconductor companies should turn to API-MS to identify, reduce and avoid defects and contamination that make high quality output a reality.

Combining analytical techniques to ensure quality

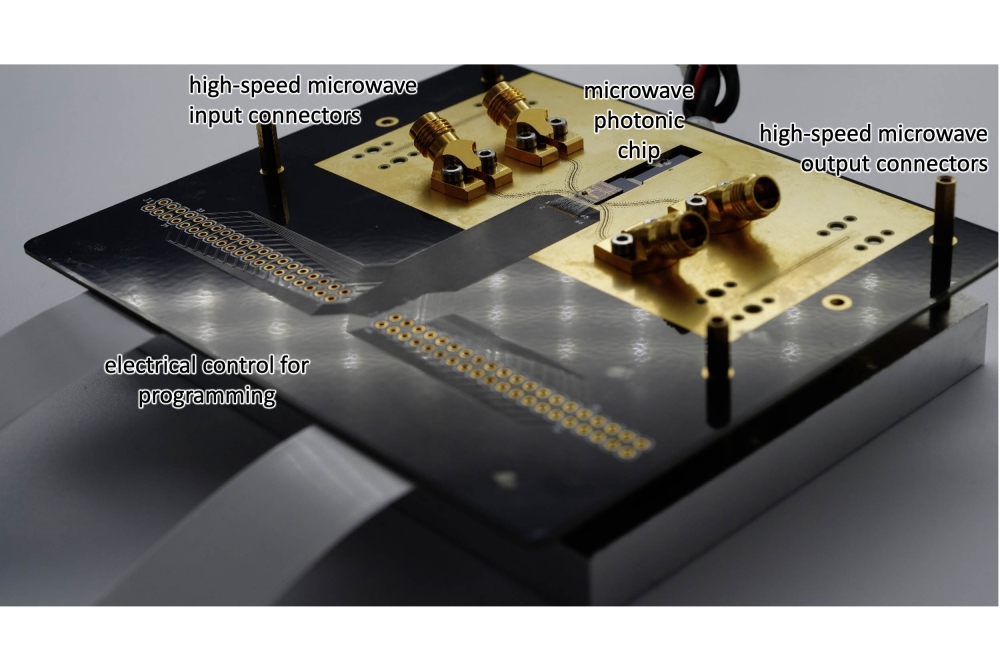

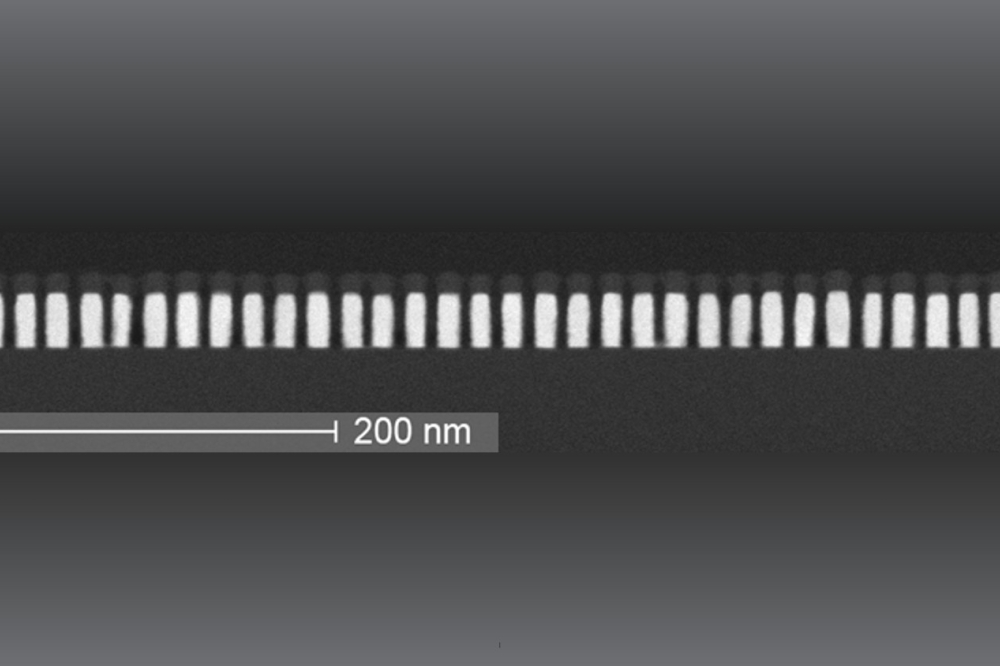

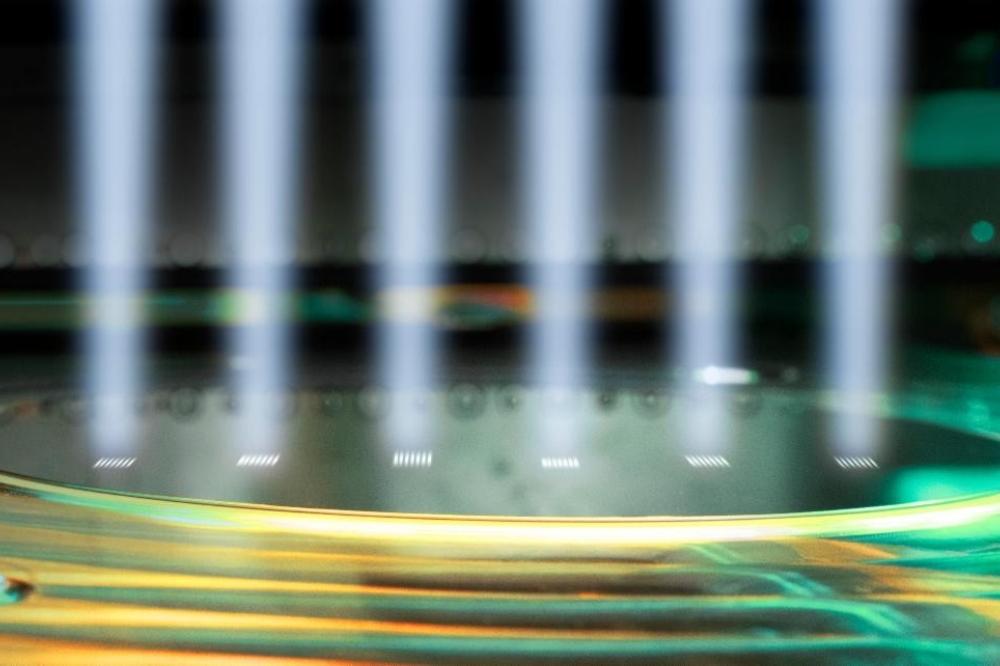

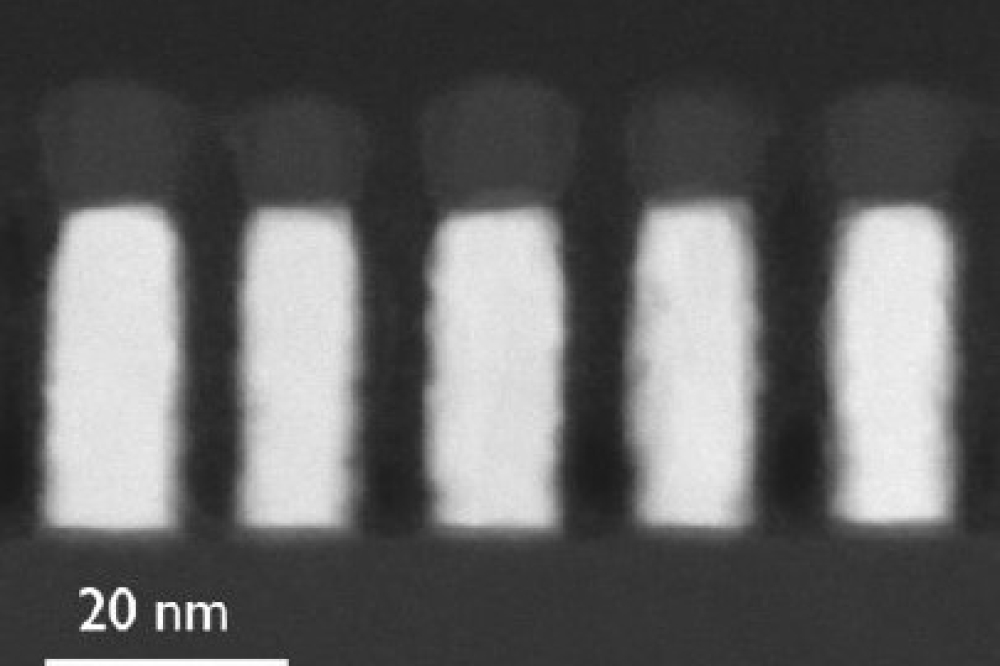

Innovation across the value chain is required to meet the demands of today’s semiconductor industry. While API-MS ensures ultra-high purity gases, advanced imaging techniques, such as scanning electron microscopy (SEM), can help manufacturers identify atomic-level structural defects in semiconductors for a comprehensive approach to quality control. SEM tools use low-voltage imaging to analyze miniaturized device features without causing damage, complementing API-MS by addressing physical fault detection.

Additionally, automation in SEM workflows streamlines data collection and enhances precision, reducing production downtime and improving efficiency in fault analysis. Integrating data from API-MS and SEM provides a holistic view of the quality assurance (QA) and QC process, enabling manufacturers to quickly identify and resolve issues, ensuring seamless semiconductor production.

The path forward led by innovative technologies

As demand for chips grows, the semiconductor industry is pushing the limits of current manufacturing capabilities. Companies that invest in cutting-edge QA/QC tools will not only keep pace with demand, but also gain a competitive advantage in a fiercely competitive global market.

Semiconductor manufacturers can create a powerful and cost-effective workflow by adopting next-generation gas analyzers and advanced analytical technologies. They can significantly reduce contamination risks, minimize production delays and maintain the integrity of their products. Precision and accuracy are imperative for quality control and quality assurance in chip manufacturing and innovative tools allow companies to address the growing complexity of devices and meet market demands. With continuous technological advancements, manufacturers are better positioned than ever to deliver high-quality, flawless devices that meet expectations across industries.