FTD solutions partners with CEA-Leti to improve water infrastructure management

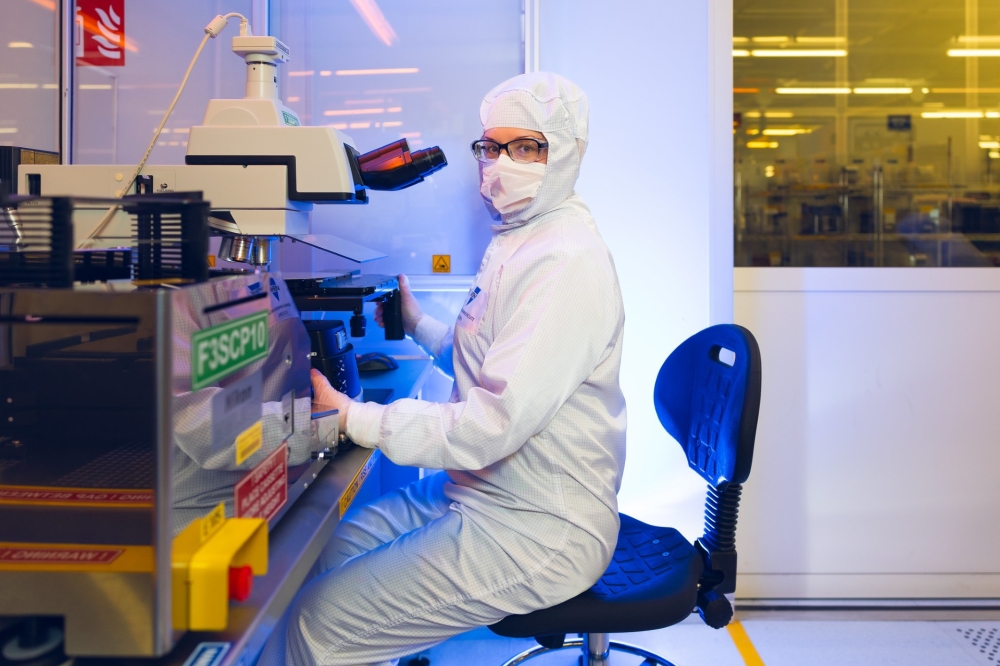

CEA-Leti has partnered with FTD solutions to evaluate and enhance semiconductor manufacturing water management strategies to meet sustainability goals, with the ultimate aim of helping to shape best practices and drive industry-wide adoption of sustainable solutions. Slava shares some brilliant insights with Silicon Semiconductor as to sustainable water management within the sector, with a particular focus on the need for water circularity within sites.

By Slava Libman, CEO and co-founder of FTD solutions

SS: Can an we start with a quick introduction to FTD solutions?

SL: FTD stands for Facility Technology Development. The company was formed nearly eight years ago recognizing the opportunity to revolutionize efficiency and sustainability in semiconductor facilities and beyond. Our approach involves developing digital twin models of facilities, which reveal the most effective solutions for site-specific water management. We then assist solution providers in aligning their offerings with specific customer needs.

We’re talking today because you have announced a partnership with CEA-Leti in the semiconductor industry – how did this collaboration come about?

CEA-Leti is championing sustainable manufacturing initiatives in Europe. Our collaboration began two years ago when I met Laurent Pain, a sustainability executive from Leti, in San Francisco. Our shared mission became clear immediately. We initially collaborated on developing a site water model and water conservation solutions for Leti’s facility in Grenoble. Now, based on the success of this initial project, we’re ready to collaboratively bring water circularity best practices to the broader industry.

SS: And the partnership is focused on sustainable water management in this sector?

SL: Yes, primarily. We are also exploring opportunity with energy management.

SS: More generally, how would you characterise the semiconductor industry’s approach to water use as of now and, crucially, where does it need to be (i.e. maybe not in Arizona?!)?

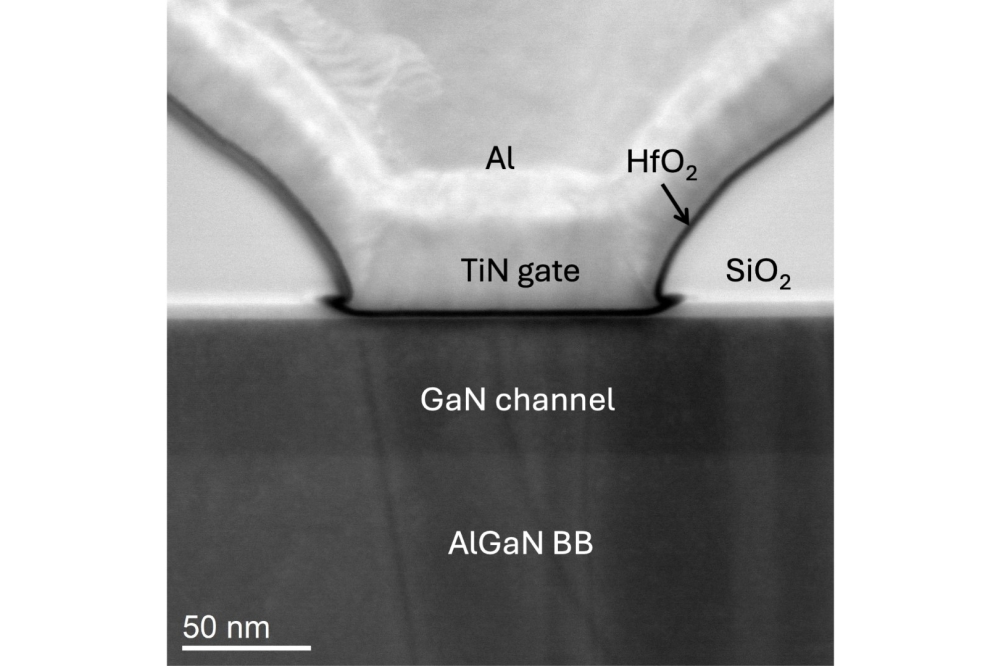

SL: Water is perhaps the most critical resource and infrastructure component in semiconductor fabrication. The industry’s approach to water usage continues to evolve, with each successive generation of technology requiring increased water for both process and non-process applications. Process applications demand more water due to the rising number of layers in semiconductor devices, while non-process uses require additional water for air abatement and evaporative cooling in energy-intensive plants.

A significant shift in the industry’s approach can be defined by the emerging concept of “water circularity.” Previously, the focus was on purifying incoming water to ultrapure water (UPW) standards and subsequently treating wastewater to ensure compliance. The new emphasis is on conservation and reuse, creating circular interdependencies between various water systems and introducing new challenges for site water management.

Regarding location choices, factors like trained workforce availability, supply chains, land, and business environment play critical roles. While water availability is recognized as important, it is typically not the sole determining factor.

SS: In order to achieve success when it comes to sustainable water management, what needs to happen; what does the roadmap look like?

SL: Sustainable water management relies more on the continuity and consistency of data-driven decisions than on specific water treatment technologies. Current technologies generally meet industry needs; the complexity arises from water being inherently local. Facilities must therefore be tailored and optimized according to local conditions, making standardization difficult.

To successfully achieve water circularity, we firmly believe holistic visualization of site water systems and generating actionable insights for data-driven decisions are essential. A clear roadmap requires establishing a known baseline, clearly defining goals and boundaries, and formulating an optimal solution strategy. This strategy is crucial for selecting appropriate water technologies to ensure cost-effective and reliable operations.

SS: For example, the Genesis Project, of which CEA-Leti is a part, is looking to address sustainable water management?

SL: As far as I understand, sustainable water management is part of the Genesis project’s scope. We are honored to support this initiative both directly and through our involvement with the IRDS organization.

SS: What are the challenges to be overcome along the way in terms of semiconductor water usage – and what role does FTD have to play?

SL: The industry’s challenges are substantial. First, the scale and complexity of new facilities under construction will exponentially increase reliability, cost, and compliance issues. Unless adequately prepared, overcoming these challenges will be very difficult. FTD’s role is to assist facilities to prepare and help navigate these challenges effectively.

Second, there is a growing demand for water expertise at a time when the number of industry experts is decreasing. FTD helps minimize the time experts spend on data collection and management, maximizing their productivity and impact.

Third, the next generation of facilities has heightened sensitivity to yield and reliability issues, requiring highly robust infrastructure. Leveraging advanced technologies, machine learning, and AI is critical, and FTD plays a vital role in enabling these innovations for site water management.

Finally, optimizing water management without negative environmental impacts is crucial. Recently, industry roadmap organizations like IRDS and SEMI Standards developed a new KPI framework to guide the industry in selecting water technology solutions with lower environmental footprints. FTD actively contributes to this initiative.

SS: And how does the semiconductor industry compare with other sectors when it comes to sustainable water management – can it learn lessons from elsewhere and/or share its learnings?

SL: The complexity of semiconductor facilities is unparalleled. Historically, this sector has led innovation, developing technologies later adopted by other industries.

SS: Which brings us to the importance of sustainable water management across all industry sectors – has there been too much focus on carbon emissions and general pollution reduction and not nearly enough focus on the looming threat of global water scarcity?

SL: It is often true that water scarcity receives less public attention than global warming, partly because water access is generally guaranteed and subsidized by governments. I personally believe energy and carbon emission challenges will likely be solved faster than water scarcity. Consequently, we must proactively manage water usage to create time for developing necessary water infrastructure, such as desalination plants and improved waterways. Effective water management today reduces demand and frees resources for infrastructure development.

SS: Set against the issues we have discussed, what does the FTD roadmap look like – how is the company looking to help shape the debate and, perhaps more importantly, the concrete actions which need to happen, and quickly?

The core strength of FTD’s value proposition lies in catalyzing immediate action and fostering innovation at scale. With our scalable solutions, we are uniquely positioned to support significant industrial facility needs swiftly and effectively. Now is a pivotal moment for industry leaders to engage proactively with us, accelerating the transformation of water management practices and gaining a competitive advantage in sustainability leadership.