Predictive maintenance in the semiconductor sector: how Edwards Vacuum is shaping the future of reliability

Predictive maintenance for vacuum pumps is no longer an experimental idea — it is a proven value driver in semiconductor fabs worldwide. By marrying decades of vacuum science expertise with cutting-edge data science and AI, Edwards Vacuum has built a leadership position in this critical domain.

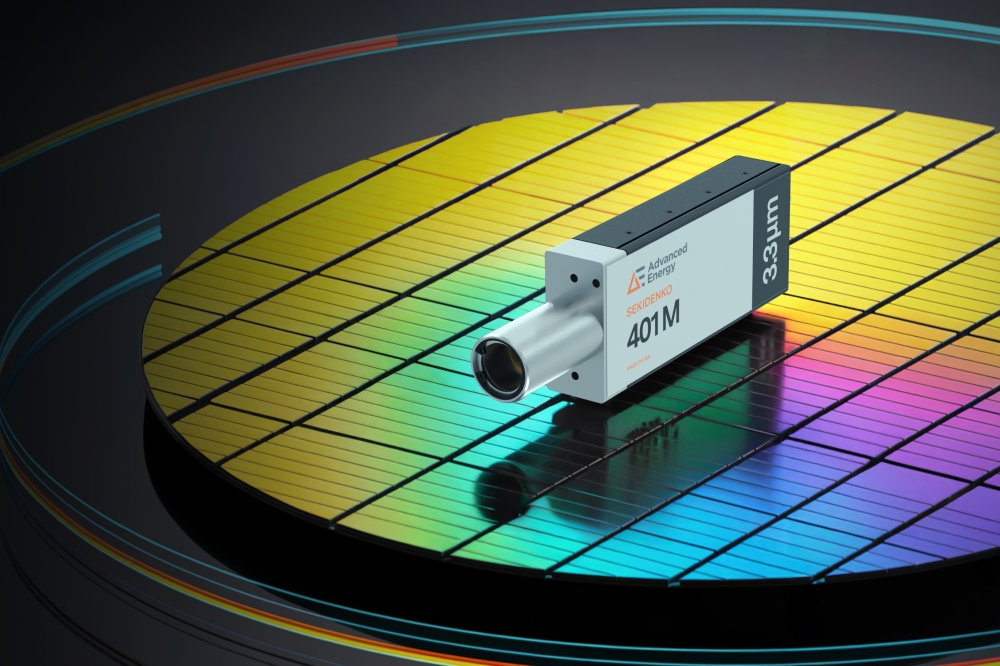

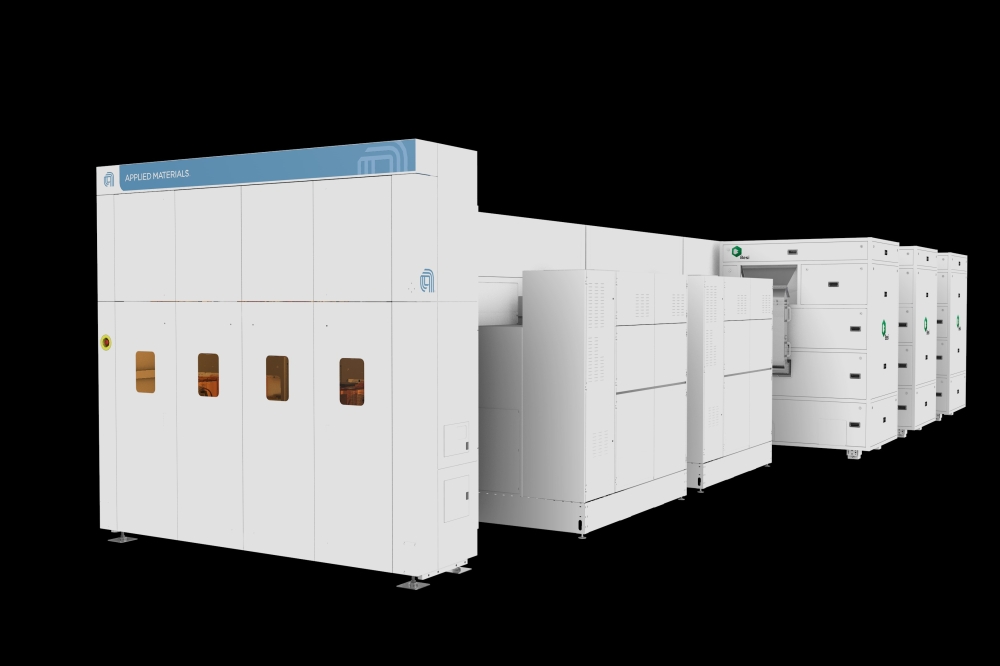

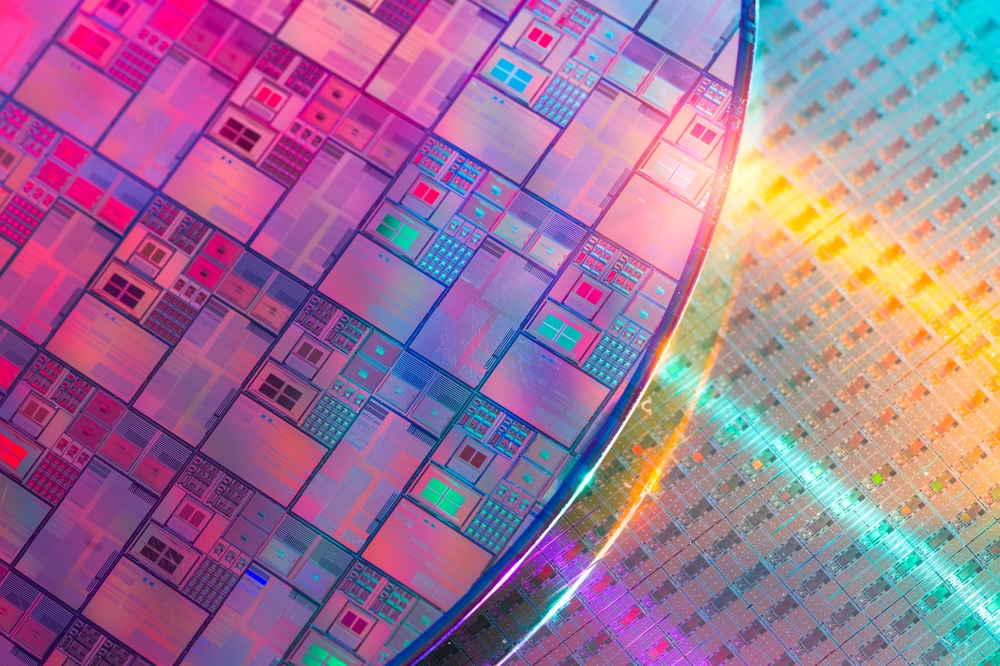

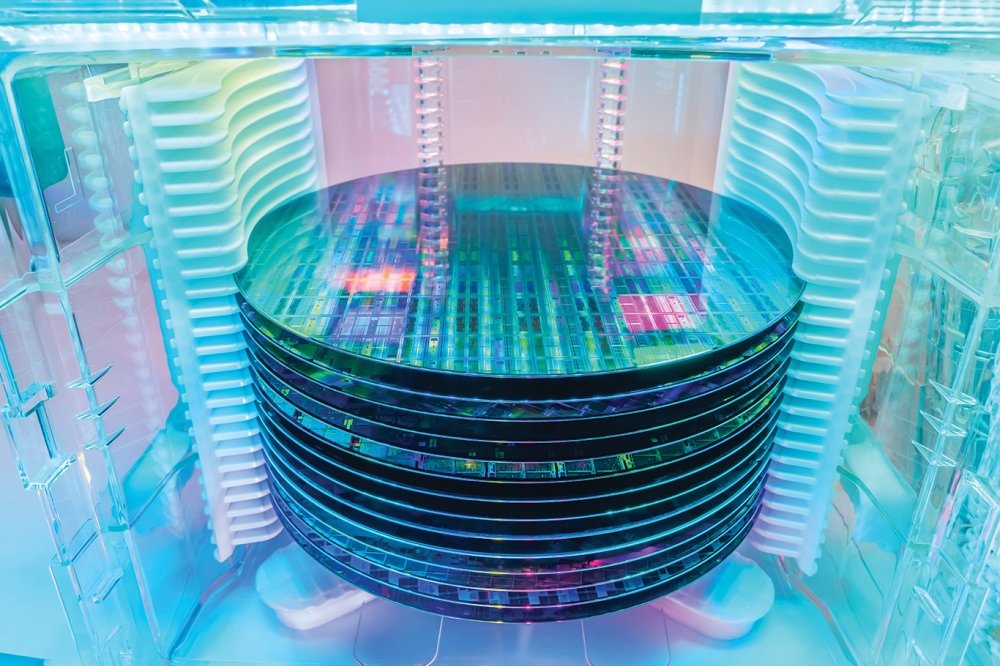

Semiconductor manufacturing is an unforgiving business. The complexity of the processes, the astronomical value of wafers, and the constant pressure to drive down cost while scaling up performance mean that every piece of equipment in a fab must operate with absolute precision. Among these critical systems are vacuum pumps, the often-overlooked workhorses that underpin etch, deposition, and other fundamental processes.

When a vacuum pump fails unexpectedly, the consequences can be catastrophic. A single wafer can be worth tens of thousands of dollars; in batch processes, an entire lot could represent millions in scrapped product. In an industry where margins are thin and throughput is paramount, the ability to predict and prevent vacuum pump failures is no longer a nice-to-have — it is a strategic necessity.

This is where predictive maintenance comes in. While preventive maintenance schedules have long been a feature of fabs, the ability to forecast failures before they happen, based on real data rather than arbitrary calendars, has transformed expectations. And at the forefront of this transformation is Edwards Vacuum, a global leader in vacuum and abatement solutions for semiconductor manufacturing.

This article explores the evolution of predictive maintenance in the semiconductor sector — from pre-AI roots to the latest machine learning and digital twin models — and examines how Edwards Vacuum is deploying data science, domain expertise, and IoT technology to deliver game-changing value to its customers.

From preventive to predictive - an historical perspective

Before the rise of AI and machine learning, predictive maintenance largely relied on rules-based approaches. Engineers would monitor key parameters — vibration, temperature, power draw, exhaust composition — and set thresholds for when interventions should occur. Using decision trees and other statistical models, these early predictive maintrenance systems achieved respectable accuracy,

often outperforming time-based schedules.

The foundations of machine learning were laid decades ago, but it is only in the last 15 years that computing power has caught up with the theory. Edwards and other advanced manufacturers were already experimenting with digital twins and rule-based models well before AI became a buzzword.

On vacuum abatement equipment, these models proved particularly effective; for dry pumps, accuracy was more challenging but still offered tangible benefits compared to rigid maintenance calendars.

The real game-changer, however, came when better data capture and higher-quality sensor inputs met the rise of advanced machine learning. By investing heavily in data acquisition infrastructure, Edwards set the stage for a step change in predictive accuracy. With high-resolution time-series data streaming from pumps, machine learning models could spot subtle signatures that precede failure — signatures invisible to rules-based systems.

The cost of failure - why prediction matters

In semiconductor fabs, two basic maintenance strategies historically dominated:

• Run-to-fail – Pumps and abatement are operated until they break. This is common in single-wafer processes where the loss of one wafer is painful but manageable.

• Scheduled replacement – Pumps and abatement are swapped at conservative intervals to prevent catastrophic failures during batch processing, where dozens or even hundreds of wafers are at stake.

Both strategies carry heavy costs. In run-to-fail scenarios, every failure risks unplanned downtime and lost product. In scheduled replacement regimes, pumps are often serviced or replaced long before their useful life is exhausted. Edwards engineers routinely find pumps that are “clean as a whistle” internally, removed only because the schedule said it was time.

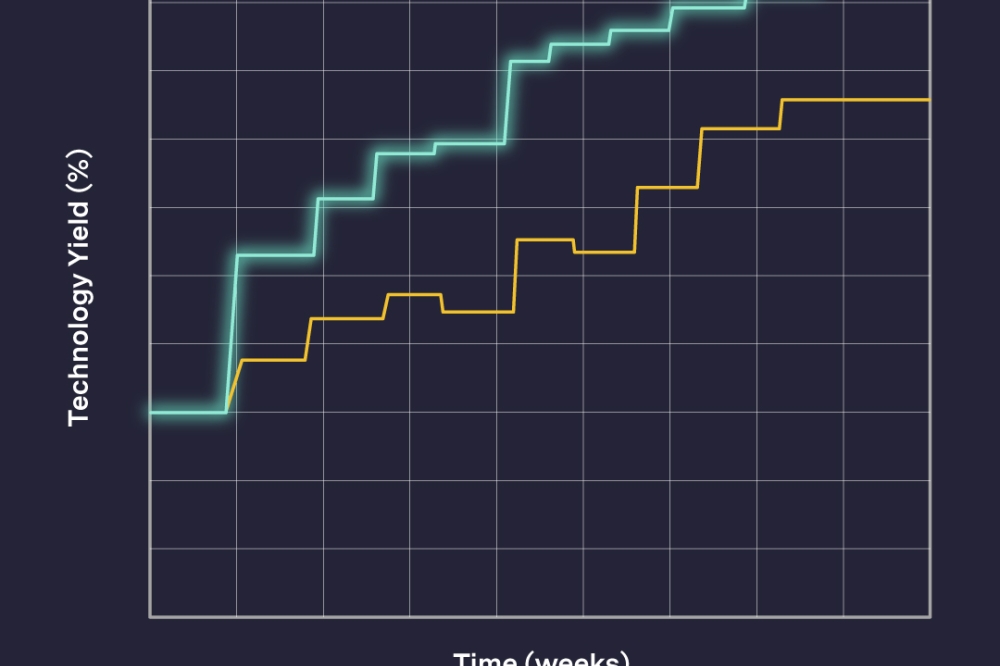

Predictive maintenance provides a third path: run-to-predict. Instead of guessing, fabs can use real data to make informed decisions. Vacuum systems can be operated closer to their true limits without crossing them, minimizing both scrap risk and unnecessary replacements. The Edwards approach is tailored.

Tailored models for specific failure modes

A key insight from Edwards’ work is that not all pump failures are created equal.

Vacuum pumps in semiconductor fabs are exposed to hostile environments - corrosive gases, deposition byproducts, and extreme duty cycles.

Different processes lead to different degradation mechanisms. For example, corrosion occurs gradually as corrosive gases attack pump internals. These are relatively easy to detect, as degradation trends are slow and steady. In contrast, when it comes to deposition byproducts accumulating inside the pump, leading to blockages or seizure, these failures are more abrupt and therefore harder to predict.

Rather than attempting a “one size fits all” predictive model, Edwards builds specific models for each failure mode and pump family, tuning them to the customer’s process conditions remarkable results, with prediction accuracies north of 95% for corrosive processes and 70-90% accuracy for depositive processes, depending on the customer and the specific process.

These accuracies are 30 -40% higher than attempts to use generic models. The lesson is clear - domain expertise and failure-mode specificity matter just as much as raw machine learning power.

The data advantage – needles and haystacks

Machine learning thrives on data — but without domain knowledge, models can mistake noise for signal. Edwards’ advantage lies not only in the sheer volume of pump performance data it has accumulated over decades, but in its deep vacuum science expertise. Building predictive models is a little like looking for a needle in a haystack. AI can sift the hay faster, but Edwards knows what a needle looks like. By combining physics-based insights with statistical analysis, this avoids false positives and delivers actionable intelligence.

This fusion of human expertise and algorithmic insight is what makes Edwards’ predictive maintenance solutions robust in real-world fabs.

Dollars and downtime

Ultimately, fabs care about total cost of ownership (TCO) and yield protection. Predictive maintenance delivers on both fronts.

While Edwards guards its proprietary ROI calculators, the company can quantify benefits for each customer by analyzing historical pump failures, wafer scrap events, and unplanned maintenance. For many fabs, the savings run into hundreds of thousands of dollars per year, by moving breakdown maintenance to corrective maintenance.

But the benefits extend beyond customer savings. Predictive insights allow Edwards itself to optimize its service network. For example, if the company can forecast a quantity of potential pump failures across a region weeks in advance, it can stock the right spare parts, schedule the right number of technicians, and streamline logistics. This not only reduces Edwards’ operating costs but ensures faster, smoother service for customers.

Beyond prediction - optimization and self-tuning

Predictive maintenance is not just about avoiding failure; it also opens the door to optimizing vacuum system performance.

By analyzing operational data, Edwards’ teams often discover simple configuration tweaks — for example, adjusting pump temperature by a few degrees — that dramatically reduce failure risk. These insights, delivered as part of Edwards’ service packages, represent an additional layer of value beyond prediction.

Looking ahead, Edwards envisions a future where pumps may be able to reconfigure themselves autonomously in response to changing process conditions. While industry conservatism and safety concerns make this a longer-term goal, the trajectory is clear: predictive maintenance is evolving into prescriptive maintenance, and eventually toward self-optimizing equipment.

Building and deploying the models

Edwards’ predictive maintenance models are structured around standard models for pump families and failure modes and customer-specific tuning, enabled by a sophisticated simulation environment.

By replaying years of pump data in a matter of hours, Edwards can test and refine models before deploying them live. This rapid iteration allows them to demonstrate predicted hit rates with confidence and customize solutions without prolonged trial-and-error on the fab floor.

Deployment is flexible. Edwards’ data platform is designed cloud-first, offering scalability, real-time monitoring, and fleet-level visibility. For customers wary of the cloud, edge deployments are possible — either on-site or within the customer’s own private cloud.

Alerts and decision-making can be handled by Edwards’ service teams, integrated into fab management systems, or both. The flexibility reflects a key principle, that customers choose the level of autonomy they want, while Edwards protects the proprietary core of its models.

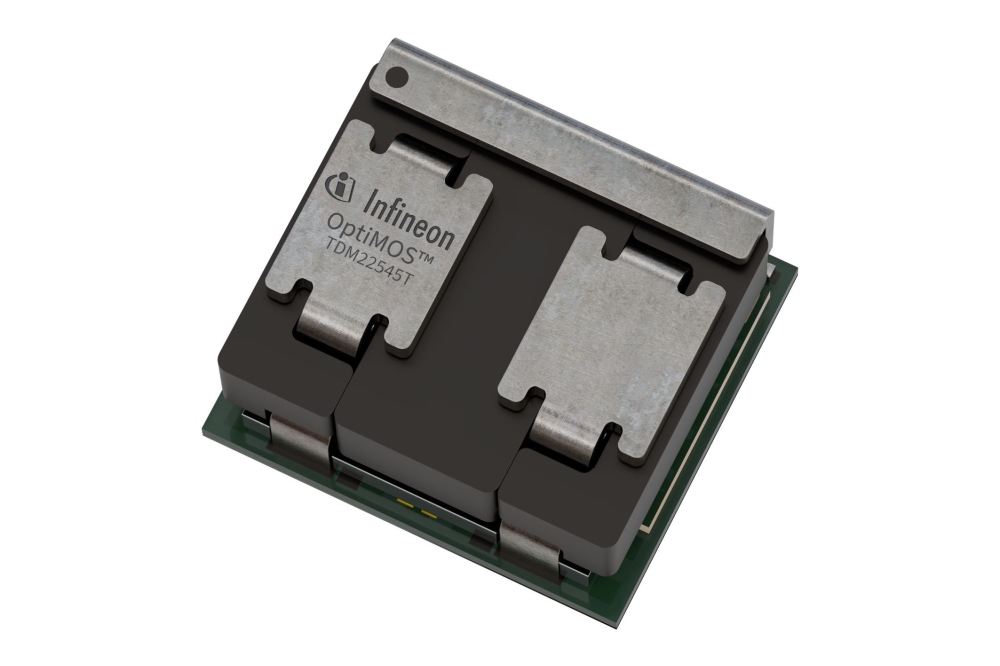

Next-generation pumps - Ganymede and IoT in action

Edwards’ upcoming Ganymede platform exemplifies the convergence of predictive maintenance and IoT. Unlike previous pumps, where the control and communication functions were bundled on a single microcontroller, Ganymede introduces a dedicated gateway controller with substantial compute power.

This allows predictive models to run directly on the pump itself, reducing latency and dependency on external systems. Data still flows into EdCentra for fleet-level oversight, but the pump becomes more autonomous, embodying the long-promised vision of industrial IoT. The IoT hype cycle has passed through its ‘trough of disillusionment’, what remains is a mature, pragmatic use of connected devices — and Ganymede is poised to be a flagship example.

The role of digital twins

Digital twins — virtual replicas of physical systems — are another AI frontier for Edwards. The company’s service centre teams are already using twins of maintenance facilities to simulate pump flows and optimize operations.

For predictive analytics, the challenge is tougher: accurately modelling the physics of a vacuum pump in real time is enormously complex. Edwards is tackling this incrementally, starting with subsystems like cooling circuits. The long-term goal is to combine physics-based twins with machine learning models, yielding hybrid approaches that are both interpretable and accurate.

Full pump digital twins may be several years away, but the trajectory is set - twins will complement AI by embedding physical causality into predictive systems.

Toward deeper fab integration

One exciting prospect is integrating pump data with process tool data. In theory, knowing process gas flow rates or chamber conditions could make predictive models even more accurate. In practice, fabs are fiercely protective of recipe data, and OEMs guard their equipment telemetry closely.

This is a longstanding cultural barrier, rooted in the semiconductor industry’s history of secrecy and ‘paranoia’. Yet there are signs of progress. Edwards can already show how combining pump and abatement system data — both under its umbrella — improves prediction accuracy. Extending this logic to fab-level integration may be inevitable, especially under the combined pressures of sustainability, yield, and cost efficiency.

The challenge will be coordinating collaboration across OEMs, fabs, and suppliers while maintaining confidentiality. Initiatives like SEMI standards and third-party data platforms may provide the neutral ground needed.

Overcoming human and cultural barriers

Predictive maintenance is as much a people challenge as a technical one.

Operators with decades of experience often pride themselves on their “gut feel” for when equipment is failing.

Far from displacing this expertise, Edwards’ models often validate it, providing data-driven confirmation. Resistance does exist, but results speak louder than scepticism. Once engineers see higher uptime and fewer scrapped wafers, they tend to embrace the technology.

At a broader level, the semiconductor industry’s caution toward cloud adoption remains a barrier. Concerns about data leaving the fab walls are deeply ingrained. Yet as Edwards points out, the very IT security technologies developed by the semiconductor industry underpin the safety of cloud systems used in banking, pharma, and other critical sectors.

For Edwards, the vision is clear - a ‘control room’ model (similar to the Rolls-Royce aerospace approach), where specialists monitor pump performance worldwide in real time and proactively guide maintenance. Achieving this requires industry-wide comfort with cloud-based data sharing — a cultural shift that is gradually unfolding.

The road ahead

Edwards’ predictive maintenance journey is still evolving. The near-term roadmap includes:

• Wider deployment of cloud-first data platform.

• Rollout of Ganymede pumps with onboard predictive capability.

• Continued progress on digital twins for subsystems.

• Exploration of deeper fab integration under secure data-sharing frameworks.

• Leveraging predictive insights for Edwards’ own service network optimization.

Longer-term, the possibilities include autonomous self-tuning pumps, AI-driven operational efficiency across regions, and hybrid models combining machine learning with digital twins.

In every case, the goal is the same: to reduce downtime, extend pump lifetimes, and protect yield in one of the most unforgiving industrial environments that exists.

Conclusion

Predictive maintenance for vacuum pumps is no longer an experimental idea — it is a proven value driver in semiconductor fabs worldwide. By marrying decades of vacuum science expertise with cutting-edge data science, Edwards Vacuum has built a leadership position in this critical domain.

From tailored failure-mode models to IoT-enabled next-generation pumps, from service-centre digital twins to visions of real-time global monitoring, Edwards is demonstrating how predictive maintenance is evolving into a broader paradigm of predictive operations.

In the relentless pursuit of yield, uptime, and efficiency, predictive maintenance is not just about pumps — it is about the future of semiconductor manufacturing itself. And Edwards is helping to write that future, one (AI-enabled) pump at a time.