Onto Innovation announces new acoustic metrology products

Onto Innovation has announced the next evolutionary step of innovative acoustic metrology products. The new Echo™ system further expands the addressable market for in-line characterization of opaque films, which is estimated to be approximately $110 million, by leveraging the principle of picosecond ultrasonics to deliver critical thickness metrology and material characterization for key technology transitions in the leading-edge DRAM and high-stack NAND memory markets. For these advanced architectures, the Echo system provides critical metal film metrology enabling higher memory bandwidth and bit density. In specialty segments, the Echo system provides metal thickness and characterization for a variety of devices, including RF filters for 5G communications, and power devices for the rapidly growing electric vehicle (EV) and high-speed portable charger markets.

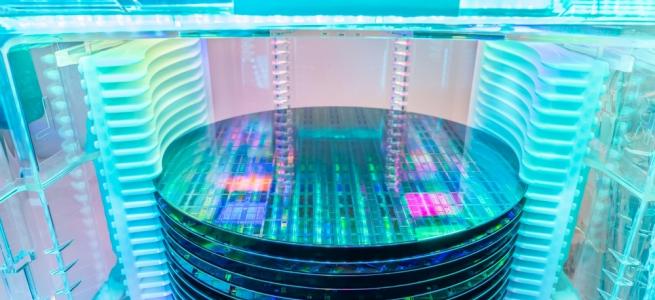

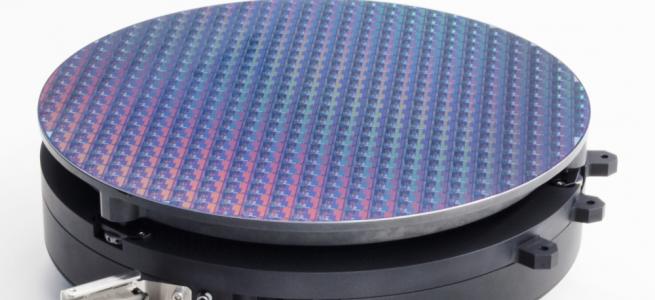

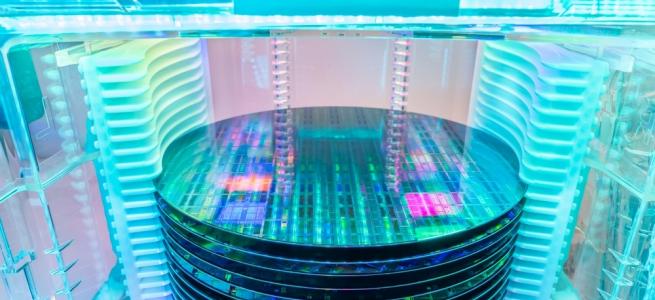

Onto Innovation’s Echo opaque film acoustic metrology product. Capable of single or multilayer film measurements from 50Å to 35µm, handling 100-300mm wafer sizes. (Photo: Business Wire)

Onto Innovation’s Echo opaque film acoustic metrology product. Capable of single or multilayer film measurements from 50Å to 35µm, handling 100-300mm wafer sizes. (Photo: Business Wire)

Operating at three times the signal-to-noise ratio (SNR) of existing products, the Echo system supports a wide range of film thicknesses, from very thin 50Å films up to 35µm opaque films and metal layers. Furthermore, the Echo system has materials characterization capabilities that include in-line time domain thermo-reflectance for implant monitoring and thermal conductivity characterization.

“By leveraging Onto’s tool-centric software, the Echo system offers a complete solution at HVM customer sites where on-wafer metrology measurements are used in a closed loop feedback approach to enact run-to-run process control on key enabling film deposition steps,” said Danielle Baptiste, vice president and general manager of Onto Innovation’s enterprise software business.

“As tier stacks in vertical NAND devices continue to grow, key deposition steps, such as the hard mask, are critical to the channel hole formation process. The accurate thickness and mechanical properties of these films are extremely critical to ensure that the film maintains integrity throughout the etch process,” said Priya Mukundhan, senior director of product management at Onto Innovation.

Early adoption of the Echo system has been quite strong at a variety of customers and is entering these new markets with an order backlog of $20 million.