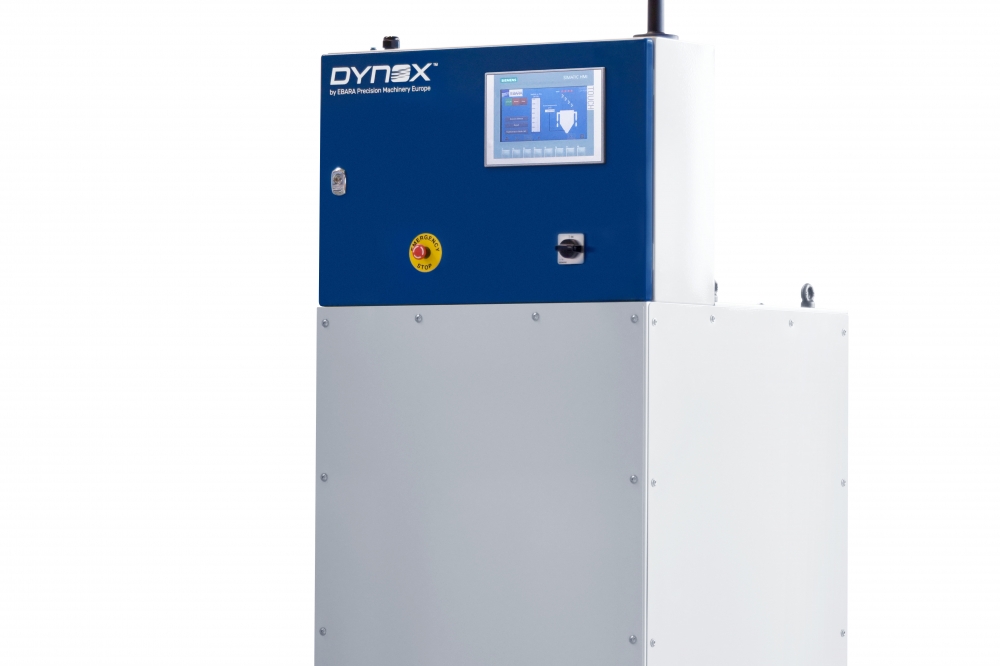

EBARA presents DYNOX Gas Abatement System

After intensive development work, EBARA Precision Machinery Europe presents the innovative and trend-setting exhaust Gas Abatement System DYNOX™. DYNOX™ sets standards when it comes to the environment and efficiency. DYNOX™ combines all the benefits of the previous S.DOC™ technology in one single product.

Thanks to advanced technology, DYNOX™ allows:

- an enormous cost savings - up to 95% lower electricity costs compared to conventional systems

- an exemplary sustainability - no gases (fuel gas, oxygen, nitrogen) are required

- an excellent environmental balance - no CO2, no NOx, only ambient air is used

- no waste heat

- cost savings also because no waste water has to be disposed of

Areas of application:

- oxidation of pyrophoric gases

Highest efficiency and thus radically reduced costs:

- easy installation, as only one component needs to be installed

- no need for piping and vacuum or water pumps

- no inflow and outflow of waste water

- no fuel gases required

- no NOx emissions

- 90 % lower energy consumption (compared to S.DOC™)

- almost no wearing parts, thus minimal maintenance effort

- 1:1 dimensions to the S.DOC™ allow easy replacement (drop-in-replacement)

- intelligent circuit concept enables control of old units

Dynamic oxidation is the most cost-effective and sustainable solution for cleaning pyrophoric exhaust gases, such as those produced in semiconductor production or photovoltaics in particular. In the past, EBARA made a statement in innovative exhaust gas abatement with the S.DOC™ system. The costs for waste water disposal are completely eliminated and since DYNOX™ does not require a circulation pump, electricity and wear costs are also reduced to an unprecedented extent.

Thanks to the sophisticated technology, the DYNOX™ installation is unproblematic and particularly inexpensive, as there are no pipes for exhaust gases or waste water. The high-quality components from Germany and Switzerland, as well as the manufacturing in our factory in Dresden, guarantee first-class quality, highest operational safety and lowest maintenance costs. The DYNOX™ complements the EBARA portfolio for environmentally friendly gas abatement.

Electricity costs are becoming an even greater expense factor

It is not only since the beginning of the Ukraine crisis that the price of electricity in Europe, and especially in Germany, has been growing extremely strongly. If production can no longer be profitable, the cost of energy also becomes a threat to the labour market. Products like DYNOX™ provide the right answer to the emerging challenges of our time. DYNOX™ requires just 10% of the energy of conventional systems with comparable performance - 2.1 kW for a pump-based system compared to 200 watts for the DYNOX™. In addition, DYNOX™ uses only ambient air.

Environment and technology in harmony

Products like DYNOX™ bring high technology, customer wishes and environmental considerations into harmony. DYNOX™ is thus in the best EBARA tradition. EBARA's goal is to develop products and services that contribute to the sustainable use of resources.