Enabling Hydrogen Purification for Process Equipment

By ARM Purification.

Hydrogen is used in many processes in the semiconductor industry, such as annealing, epitaxial growth, lithography, and as a carrier gas for hydride dopants. The use of hydrogen gas in the semiconductor industry is increasing, and along with that increase come constraints on supply chains and markets. Hydrogen generation is becoming more prevalent, as well, in order to mitigate traditional supply chain issues such as trucking, plant shut downs, and more.

It's critical to utilize the right gas purifier when working with hydrogen. Applied Energy Systems (AES), the leading provider of high and ultra-high purity gas delivery systems is focused on offering gas purification solutions for complex and myriad applications. AES’s ARM Purification division recently introduced the redesigned APS60 series of purifiers, including the APS60-CXXX series of hydrogen purifiers (XXX is the flow in Nm3/hr). For any process, ARM Purification is equipped to handle hydrogen purification; traditionally utilizing H2 from liquid, tube trailers, and other sources and purifying it to 8N or 9N outlet quality.

Challenges with Traditional Heated Media-Based Purification Technology

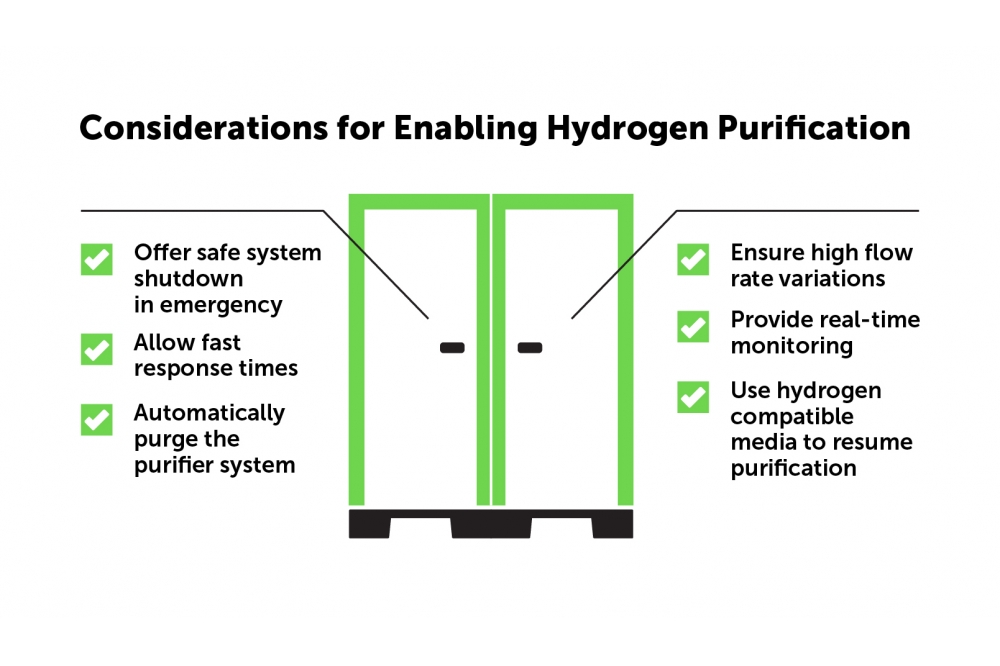

While bulk purifiers have traditionally been utilized on systems providing fairly constant flow requirements, ARM Purification has introduced the ability to provide purified UHP 9N hydrogen gas in a process environment that demands high flow rate variations and fast response times for the success of the process. These systems are sized up to 300 Nm3/Hr and are fully PLC controlled with hydrogen safety features built into the unit.

Using traditional heated media-based purification technology for hydrogen purification is somewhat difficult in applications that require high flow rate variations, such as EPI, due to the construct of the material’s reaction towards hydrogen. The traditional purification media, often a metal getter, reacts with hydrogen in a reversible manner, giving the ability to increase purifier vessel pressures and temperatures quickly upon flow demand through the unit. This is because the hydrogen can react exothermically with the media, and constitutes a reversible reaction in the media that is both temperature and pressure dependent.

Unlike oxygenated species and hydrocarbons, which are chemically bonded to the material upon reaction, the hydrogen goes into solid solution and is a reversible reaction. Therefore, under high flow requirements, the temperature increase needed to optimize purification efficiency must be monitored in real time, along with the pressure, in order to control the potential for increases in both, without the pressure loss associated with membrane H2 purifier technology.

Stringent Safety Considerations For Hydrogen Systems

The safety considerations of hydrogen systems are stringent—but with a solution like ARM’s updated APS60 platform of purifiers, there exists the ability to automatically purge the purifier system with Argon gas, and provide for a safe system shut down in case of emergency. This shut down is then followed by an automatic process to re-introduce H2 into the media, thus providing a hydrogen compatible media to resume the purification of the hydrogen gas quickly and safely. All of these processes are PLC controlled and have been fine-tuned based on system user input and design engineering parameters, include HAZOPS analysis and best practices followed from AES’ SEMI-GAS line of gas cabinet equipment, and SEMI guidelines. Some of the safety features considered standard are exhausted cabinets, Z-purge electronics, hydrogen gas sensors, and safety interlocks all designed for safe and efficient operation.

The challenges of taking a heated, getter-style hydrogen purifier from idle to full process flow conditions have been met by a combination of tight process controls which allow for temperature and flow changes quickly and effectively, and the possibility of user adjustment through the HMI within the process parameters set forth at the factory.

Solutions for Complex Challenges Made Possible with the Right Partner

ARM Purification is committed to delivering solutions for the semiconductor industry’s various challenges. ARM includes Ethernet as a standard offering, and users now have the opportunity to provide UHP H2 and real time monitoring for process hydrogen in variable flow rates for processes that require it in the most demanding semiconductor processes. The purifier system can be tied in to SCADA or process control systems for full visibility, and comes standard with sub-micron particle filtration, and the availability of industry leading 1.5 nm filtration.

If you have a hydrogen delivery application that could benefit from 9N hydrogen, but the flow variations in the process, or the high pressure loss of membrane purification technology have kept you from considering purification, ARM Purification has the product that excels under these delivery system constraints.

Learn more about gas purification that meets your unique requirements by visiting www.armpurification.com.