Cepton expands proprietary chipset

Named “Komodo,” the ASIC significantly improves lidar performance and reduces cost to drive mass-market adoption.

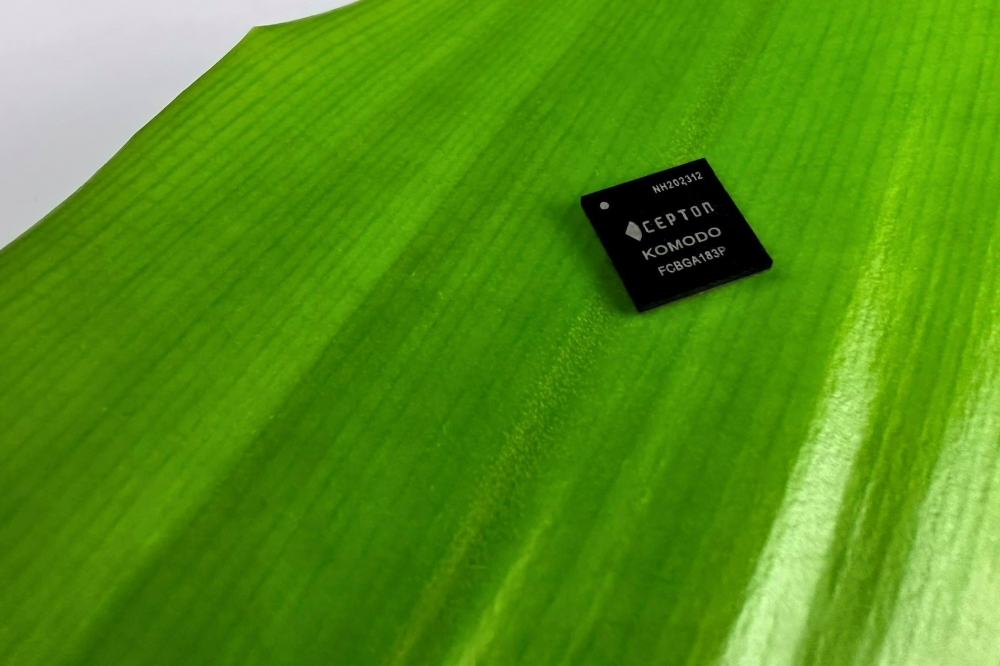

Cepton has released Komodo, its proprietary lidar point cloud processor ASIC (Application-Specific Integrated Circuit) chip.

Supported by Cepton’s deep experience in industrializing automotive lidar for volume production through the company’s flagship ADAS lidar series production program, Komodo successfully achieved production-ready status and is expected to begin shipping in Q2 2023.

Developed in-house at Cepton’s headquarters in Silicon Valley, Komodo will be integrated into several models of Cepton lidars, setting new industry-wide benchmarks for lidar performance and price.

Komodo is a highly integrated custom SoC (System on Chip) designed to maximize the technical advantages of Cepton’s patented lidar architecture to significantly improve point cloud quality while replacing several merchant silicon devices to dramatically reduce cost.

“Our goal is to ultimately offer our customers a customizable black-box solution with built-in perception capabilities,” said Dr. Jun Pei, CEO and Co-founder at Cepton. “Since 2019, we’ve had a vision of developing a comprehensive chipset through a series of ASICs covering front-end signal processing, back-end point cloud processing and eventually perception capabilities all within the lidar unit. We started with our own signal processor ASIC, Iguana, and now we are proud to unveil Komodo.

“In the context of the U.S. CHIPS bill, we see the increasing importance of minimizing reliance on the semiconductor supply chain by using our own ASICs. Cepton will continue to drive its ASIC development and expand its leadership in automotive lidar at the chip level.”

In early lidar products, lidar sensors typically relied on FPGAs (Field-Programmable Gate Array) and merchant silicon devices to generate a 3D point cloud. This prevents lidars from being optimized for mass-market commercialization, as FPGAs and merchant silicon devices result in higher costs, lower efficiency, bigger size and higher power consumption. The reliance on FPGAs and merchant silicon devices also makes lidar manufacturers more susceptible to supply chain vulnerabilities.

As Cepton’s lidar products move towards large-scale deployment, having dedicated ASICs will help Cepton achieve the price points necessary for automotive OEMs to drive mass-market lidar adoption in future vehicles. Replacing the FPGA and merchant silicon devices, Komodo significantly increases the scalability of Cepton’s lidar solutions.

Komodo is said to offer a series of key advantages:

• Superior performance: Komodo is multiple times faster than the FPGA and merchant silicon chips it replaces to improve sensor performance. It features sophisticated digital signal processing, such as filtering and noise reduction, resulting in more accurate range and reflectivity measurement. With a peak throughput of up to 12,000,000 points per second, it significantly enhances point cloud quality for higher resolution, which enables more accurate object detection and tracking at longer distances.

• Minimal power consumption: consuming under a watt of power, Komodo is multiple times more power efficient than the FPGA and merchant silicon chips. The low power consumption of the Komodo and Iguana ASICs is a key enabler of Cepton lidars’ unparalleled versatility in vehicle integration for everyday passenger cars, including EVs.

• 10x cost reduction: compared to the FPGA and merchant silicon chips, Komodo enables over ten times cost reduction and achieves an unrivaled cost-performance ratio for Cepton lidars.

• Significantly smaller form factor: Komodo’s small footprint and high performance facilitate streamlined electrical and optical design to achieve top-quality 3D images in an ultra-compact package.

• Automotive-grade reliability: Komodo incorporates a built-in functional safety monitor that is ISO26262 ASIL-B certified, enhancing the sensors’ automotive-grade reliability for use in passenger cars.

• Sensor fusion readiness: with multiple camera interfaces and high-speed data channels, Komodo facilitates lidar-camera data fusion and communication with control units.

The addition of Komodo further augments Cepton’s industry leadership in proprietary lidar ASIC chipset development. Its Iguana ASIC, which is a groundbreaking single-chip lidar engine for advanced illumination control and detection, has been shipped in Cepton lidar sensors for years.

“The combination of Iguana and Komodo seamlessly transforms analog signals into a fully digitized 3D point cloud,” explains Edward Wu, Director of ASIC Engineering at Cepton. “And that’s how lidar converts photons into accurate 3D measurements and ultimately provides useful information such as the size, speed, moving direction and distance of an object.”

Dr. Jun Pei adds, “Cepton’s expanded chipset further drives lidar adoption in consumer vehicles and is the result of several years of efforts to industrialize lidar for automotive series production.”