Agile Analog partners with sureCore on CryoCMOS Innovate UK project

Enabling control and measurement within the cryostat.

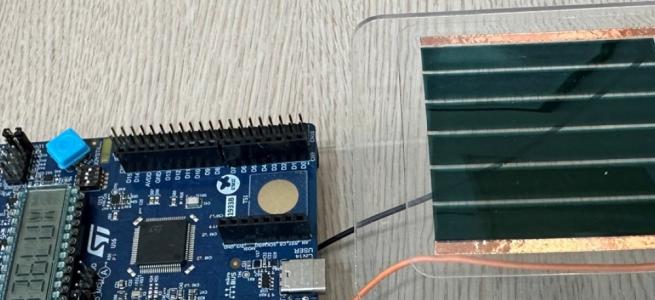

Agile Analog is collaborating with sureCore to implement a cryogenic control ASIC on the GlobalFoundries 22FDX process, as part of the Innovate UK funded project: “Development Of Cryogenic CMOS To Enable The Next Generation Of Scalable Quantum Computers.”

The consortium members created cryogenic SPICE models for the GF 22FDX process technology, and sureCore had used these to recharacterize standard cell and IO cell libraries, as well as developing low power SRAM, ROM and Register File Compilers. These cryogenic IP libraries are being used to enable the development of a test chip that will allow measurement of performance at cryogenic temperatures. Agile Analog is working closely with sureCore to implement and verify its solution.

According to Barry Paterson, CEO of Agile Analog: “We were delighted when sureCore approached us to undertake the physical design required to create a test chip for this cutting-edge project. Integrating control and measurement electronics capable of operation down to 4 Kelvin is critical to enabling quantum computer scaling. The UK is leading innovation in the quantum technology space and I am pleased that Agile Analog can participate in the development of this technology.”

Agile Analog completed the synthesis, floor planning, place and route, and design closure steps to ensure that the cryogenic test chip would be able to act as a qualification test vehicle, in order to prove that the approach adopted by this project could be a viable solution for cryogenic control ASICs.

Semiconductor process technologies are typically characterized for operation from -40C to 125C. However, in the world of quantum computing, where operational qubits demand temperatures even lower than 4K, co-locating the control electronics close to the qubits within the cryostat is crucial for quantum computer scaling. To achieve their true potential, there is a need to dramatically increase the number of qubits, from the several hundred that is possible today to millions. These qubits have to be controlled, and currently this is done by using external control electronics housed outside of the cryostat at room temperature. By generating semiconductor IP that can operate at cryogenic temperatures, quantum computing developers can quickly design their own control ASICs that can be co-located with the qubits in the cryostat.

Paul Wells, CEO of sureCore, commented on this collaboration: “Agile Analog have a unique blend of skillsets that make them the ideal partner. Their expertise and sheer professionalism ensured that we were able to work extremely closely and identify critical issues early in the project, meaning that the physical design flow proceeded in a smooth and predictable manner. Having been on both sides of the fence I can say that they are one of the best design services teams I have come across in my 35 year career.”

Barry Paterson concluded: “The Agile Analog team is pleased to be able to support sureCore, and the other consortium members, with the implementation of this platform. We have gained invaluable experience in working at challenging temperatures. The pathway to advanced quantum computers with millions of qubits relies on integrating the control and measurement within the cryostat. We can use the knowledge acquired during this project to make a range of our analog IP, including our data converters, available with support for these cryogenic temperatures. We are already having initial discussions with potential partners about delivering these solutions.”