News Article

Imec introduces compact wireless powering technology

Novel ultrasound-powering technology paves the way to miniaturized and minimally invasive neural implants, empowering healthcare technology.

Imec introduced an innovative ultrasound-based proof-of-concept for wireless powering of implantable devices, at the recent International Solid-State Circuits Conference (IEEE ISSCC 2024). The proposed solution of just 8 mm x 5.3 mm enables precise beam steering (up to a 53-degree angle) and requires 69 percent less power consumption - making it the smallest, lowest power consuming, wireless ultrasound powering unit among state-of-the-art systems. The cutting-edge concept of global charge-redistribution adiabatic driver addresses challenges associated with traditional tethered connections or batteries and paves the way for minimally invasive, wireless (neural) implants.

The need for wireless powering

Intracortical neural recordings, key for understanding and treating neurological disorders, face challenges in their powering. Traditional invasive wiring risks complications such as scarring and infection, while battery integration (removing the necessity for tethering) brings size and chemical leak concerns.

The use of global charge-redistribution adiabatic drive: a paradigm shift

Eliminating the need for invasive procedures or bulky components, imec and Delft University of Technology have designed ultrasound technology that wirelessly delivers power to neural implants, successfully traversing distances from the skull to the brain’s cortex, within the ERC-funded “Intranet of Neurons” project.

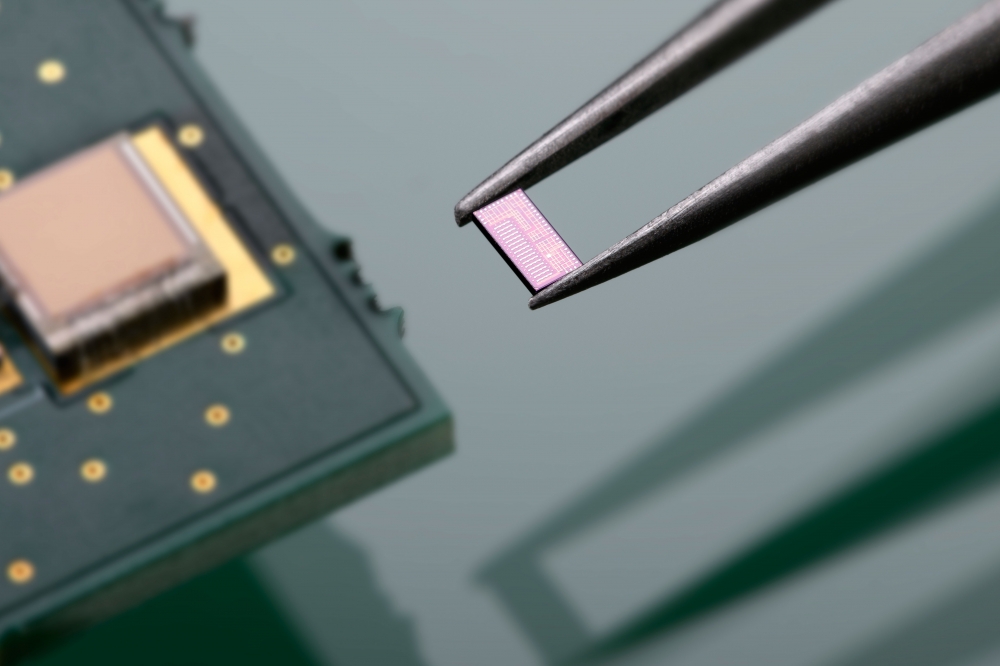

To realize this, the researchers introduced a unique adiabatic driving technique based on the concept of "global charge redistribution" (GCR). Unlike traditional adiabatic driving methods, this approach leverages the parasitic capacitors of the ultrasound transducer array itself and recycles charges. This eliminates the need for external capacitors to redistribute charges and allows for a more compact design. The chip, fabricated in 65nm CMOS, features a fully integrated 116μm×116μm driving unit that allows for 69 percent power savings compared to conventional class-D driving. This design makes it both the smallest ultrasonic adiabatic driving unit with the lowest power consumption among state-of-the-art systems.

For in vivo use, beam steering up to large angles (>45˚) is critical to maximize power delivery and compensate for brain micro-movements and misalignments (such as those occurring during surgery and respiration). With the introduction of a beam steering controller, imec’s GCR scheme enables beam steering up to 53 degrees.

“While many neural implant technologies are currently making significant progress in sensing and stimulation, wireless interfaces, as one of the crucial components of implants, still have much room for improvement - particularly in terms of power efficiency and form factor. To bridge this gap and unlock the full potential of neural implants, we are leveraging our unique wireless-, powering-, and telemetry technologies, to develop minimally invasive wireless systems tailored for miniaturized implants, with applications beyond intracortical neural implants”, commented Yao-Hong Liu, Scientific Director at imec. “We aspire to showcase the practical application of our technology in real in vivo conditions, with our ongoing advancements, particularly in areas such as micro-system integration and packaging, and welcome collaborations with medical professionals or researchers.”

The article "An Ultrasound-Powering TX with a Global Charge-Redistribution Adiabatic Drive Achieving 69% Power Reduction and 53° Maximum Beam Steering Angle for Implantable Applications," provides a detailed overview of the technological advancements, including the proposed architecture, circuit design, and performance metrics. This project Intranet of Neurons has received funding from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation program (grant agreement No. 101001448).