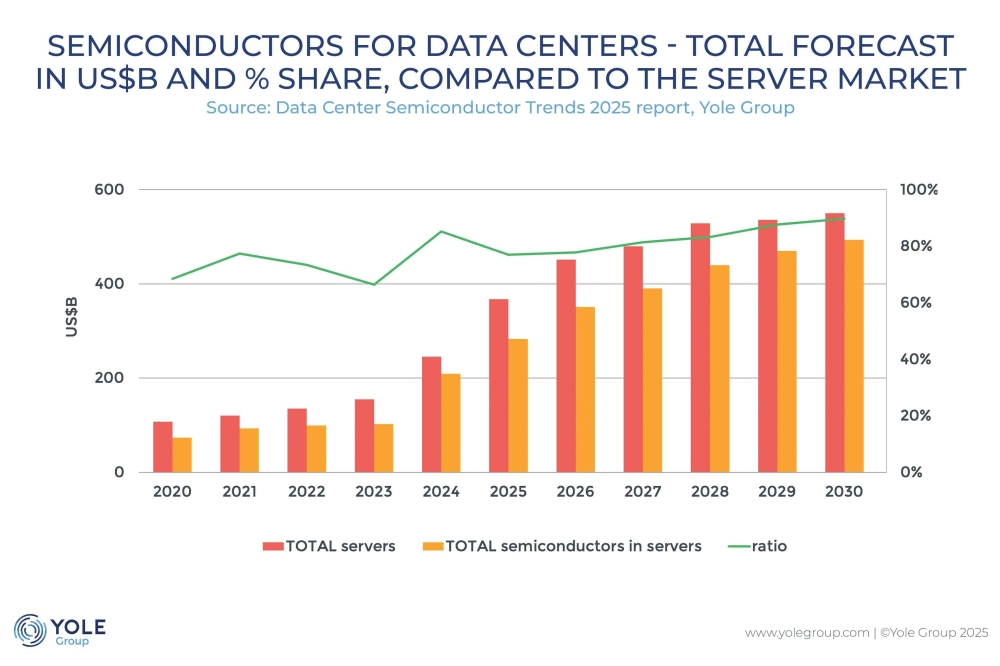

AI in semiconductor manufacturing market to surpass $14.2 billion

The market is demonstrating robust momentum, supported by a strong compound annual growth rate (CAGR) of 22.7% projected from 2025 to 2033. By the end of the forecast period in 2033, the market is expected to attain a value of USD 14.2 billion. This substantial growth is primarily driven by the increasing adoption of artificial intelligence technologies to enhance process efficiencies, reduce defects, and optimize yield in semiconductor fabrication and assembly. As per the latest research, the market’s expansion is further fueled by the growing complexity of semiconductor devices and the need for advanced analytics to maintain competitiveness in a rapidly evolving industry landscape.

Introduction

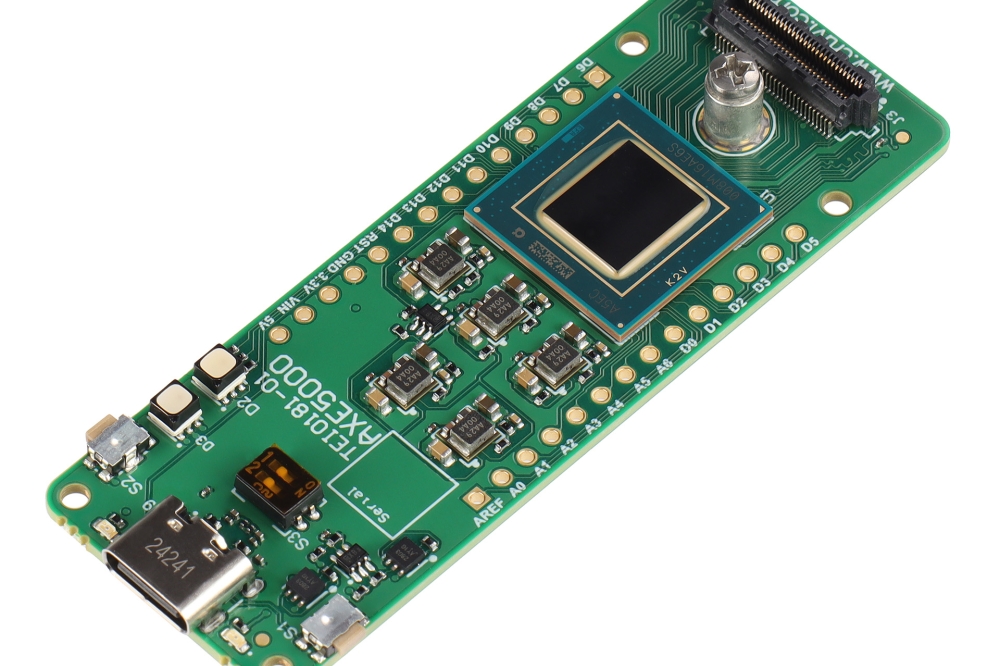

The semiconductor industry forms the foundation of the digital age, powering everything from smartphones to supercomputers. As chips grow smaller, faster, and more complex, traditional manufacturing processes face significant challenges. Artificial Intelligence (AI) has emerged as a transformative tool, enabling smarter production, faster innovation, and enhanced efficiency in semiconductor manufacturing.

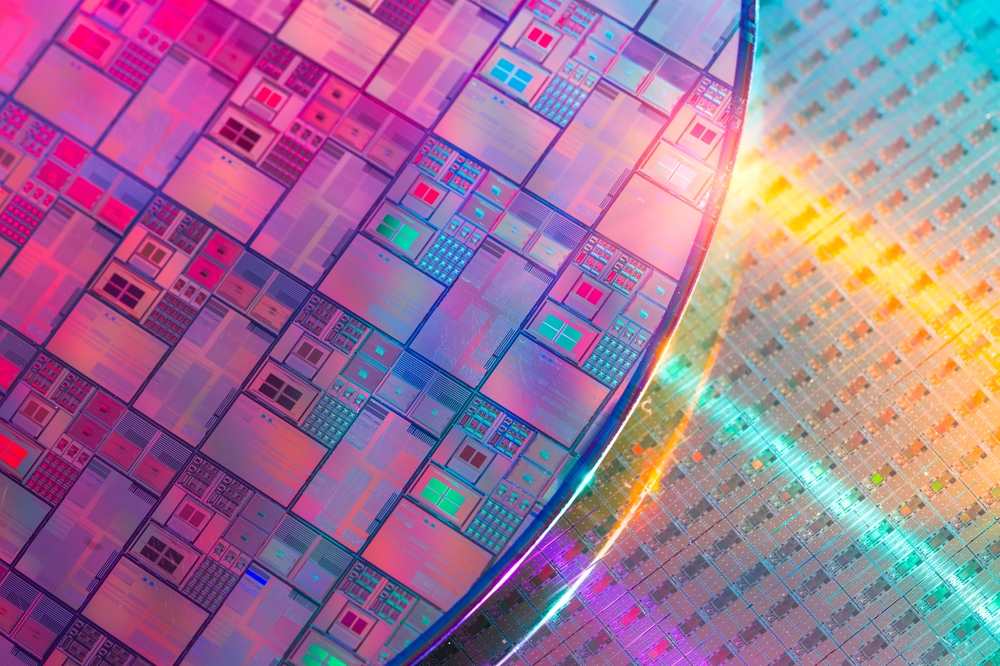

The Growing Complexity of Semiconductor Production

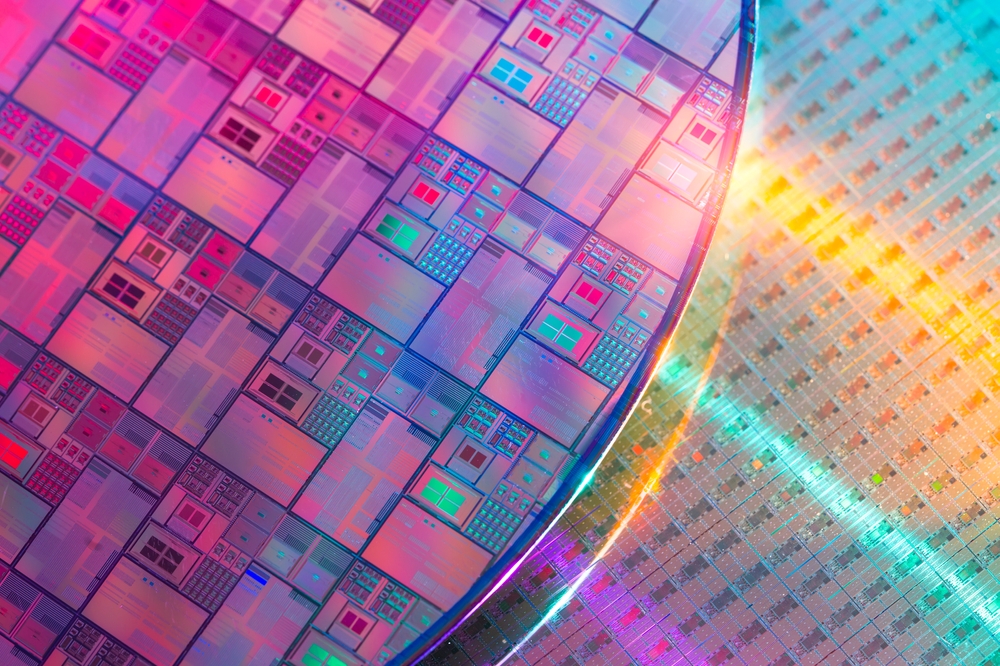

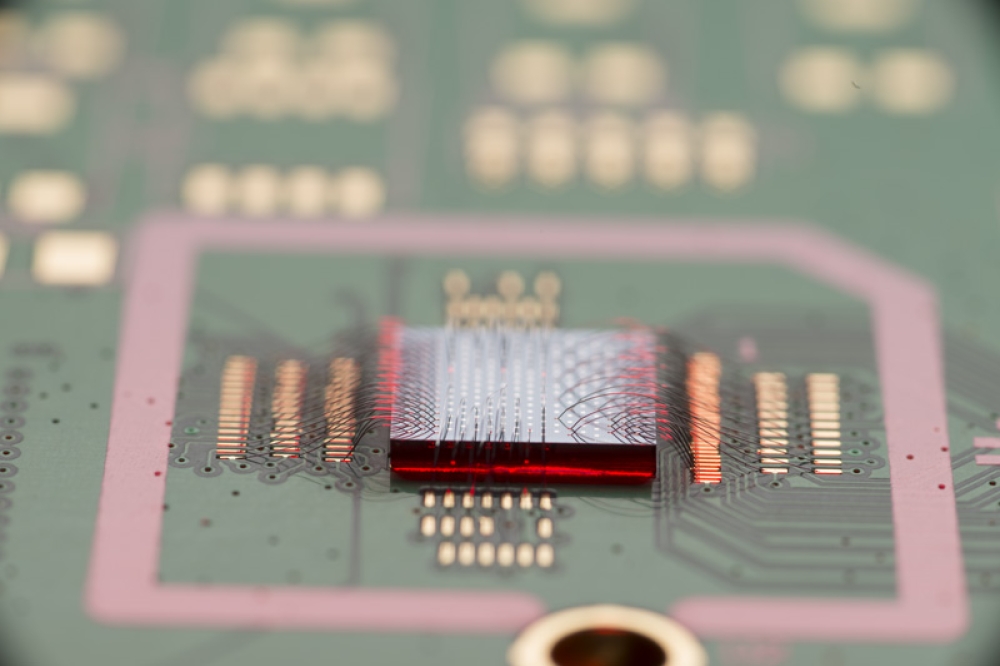

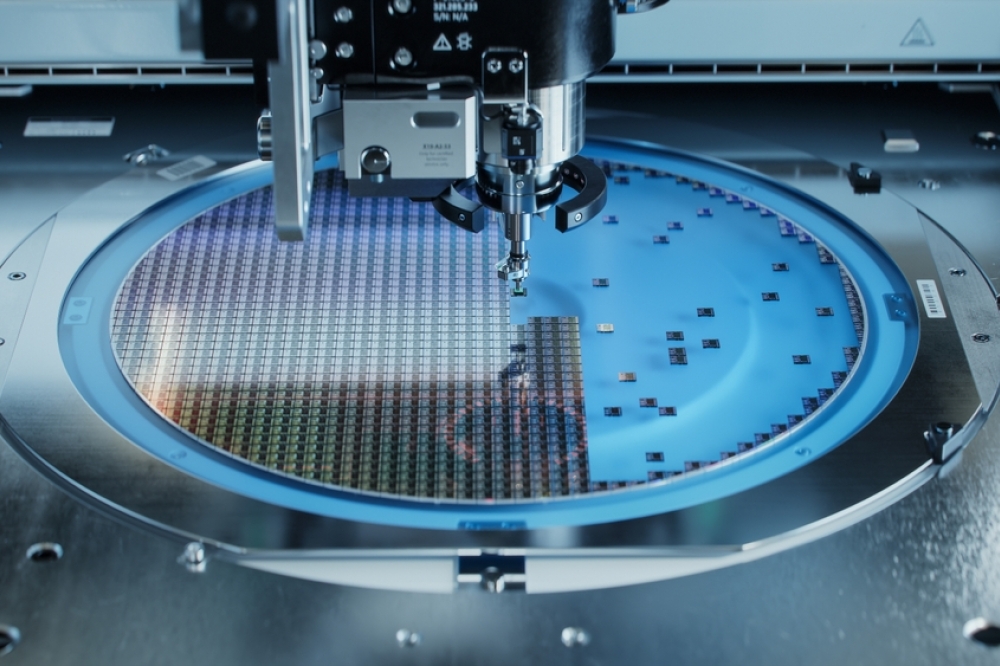

Semiconductor manufacturing involves hundreds of intricate steps, including wafer fabrication, lithography, etching, and packaging. With each new generation of chips, transistors shrink to nanoscale levels, pushing the limits of physics and precision engineering. AI helps overcome these challenges by providing predictive insights, automating defect detection, and optimizing process efficiency.

Key Applications of AI in Semiconductor Manufacturing

1. Predictive Maintenance

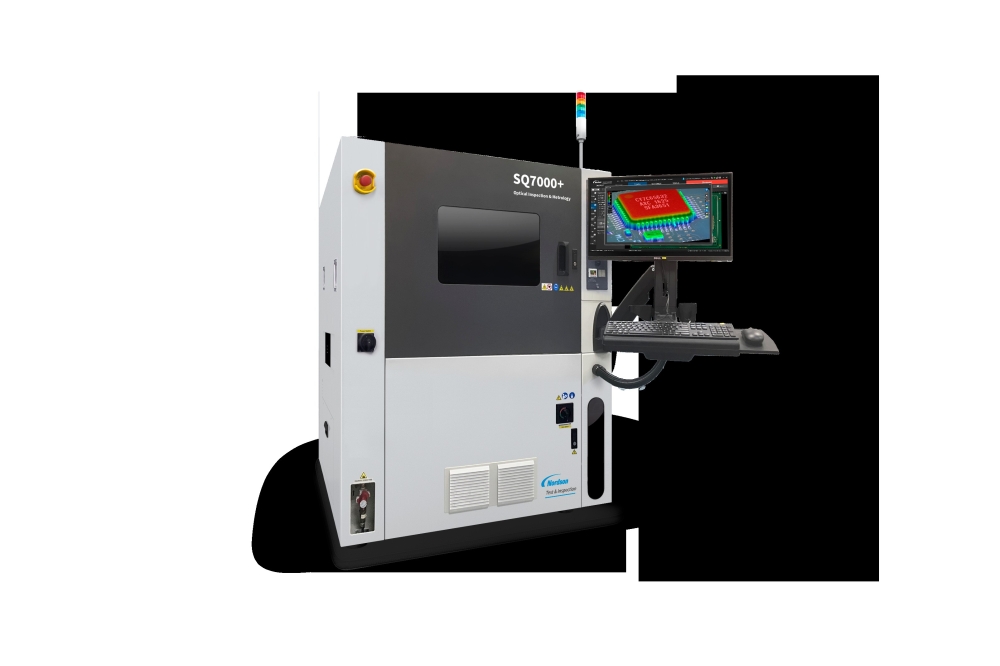

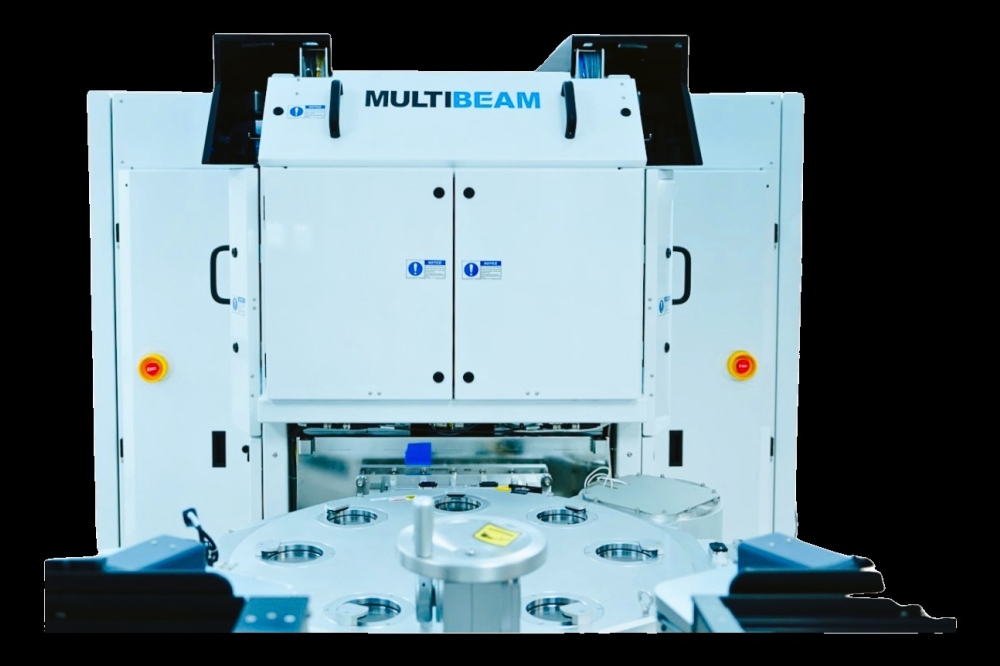

Manufacturing equipment in semiconductor fabs is highly complex and prone to wear. AI-powered predictive maintenance detects anomalies in machines, reducing downtime and preventing costly failures.

2. Yield Optimization

AI algorithms analyze vast amounts of production data to identify defects, improve yields, and enhance product quality. This ensures minimal wastage and greater cost efficiency.

3. Process Automation

From wafer inspection to testing integrated circuits, AI-driven automation reduces manual intervention and speeds up production cycles.

4. Supply Chain Management

AI models forecast demand, optimize inventory, and enhance logistics efficiency, ensuring semiconductor manufacturers remain resilient in times of global shortages.

Benefits of AI Adoption in Semiconductor Manufacturing

· Higher Production Efficiency: Reduced errors and faster production cycles.

· Cost Reduction: Lower downtime, reduced scrap, and optimized resource allocation.

· Improved Quality: Enhanced defect detection and precise manufacturing.

· Innovation Acceleration: Faster design-to-manufacturing transitions.

· Sustainability: Optimized use of energy and raw materials.

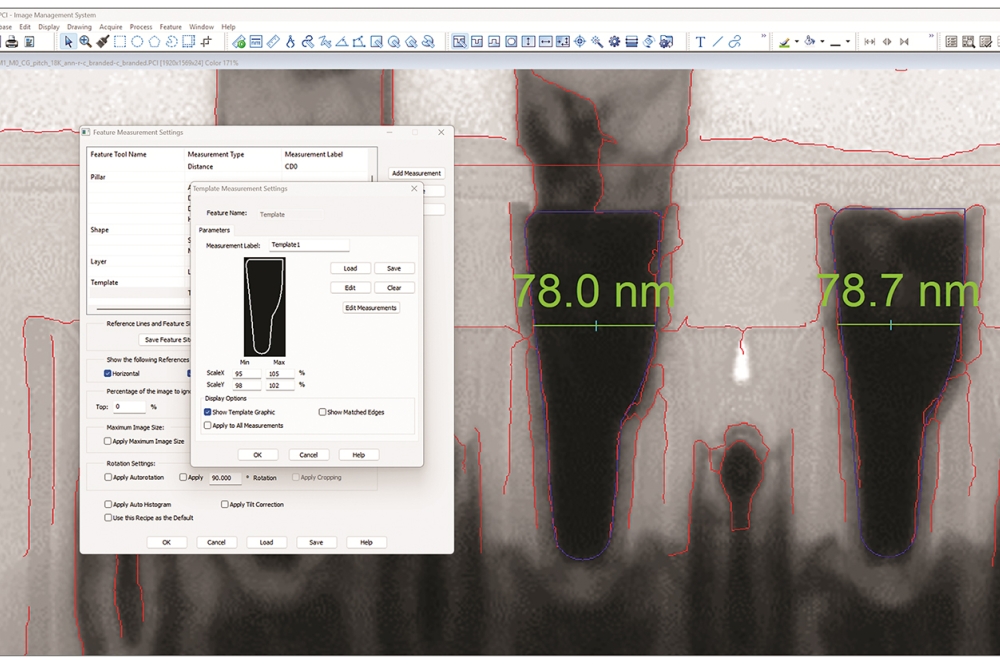

AI in Wafer Fabrication and Inspection

Wafer fabrication is one of the most critical steps in chip manufacturing, where even microscopic errors can impact chip performance. AI-based imaging systems enable:

· Real-time defect detection.

· Improved lithography pattern recognition.

· Accurate alignment of nanoscale structures.

These advancements help manufacturers achieve higher yields and improve the reliability of finished chips.

Challenges in AI Integration

Despite its promise, AI adoption in semiconductor manufacturing faces hurdles:

· Data Privacy Concerns: Handling proprietary design and manufacturing data.

· High Implementation Costs: AI infrastructure requires significant investment.

· Skilled Workforce Shortage: Combining AI expertise with semiconductor domain knowledge is rare.

· System Integration: Ensuring AI tools align with existing manufacturing processes.

Future Outlook: AI-Powered Semiconductor Ecosystem

The future of semiconductor manufacturing lies in intelligent automation and adaptive processes. AI will continue to evolve with advancements in:

· Generative AI for Chip Design: Automating early-stage circuit design.

· Digital Twins of Fabs: Creating virtual replicas of manufacturing plants for simulation and optimization.

· Edge AI: Deploying smart chips that manage their own performance.

· Sustainable Manufacturing: Using AI to minimize energy and water consumption in fabs.

Conclusion

AI is no longer an experimental tool—it is becoming a cornerstone of semiconductor manufacturing. By enhancing efficiency, reducing costs, and enabling innovation, AI is driving the industry toward a new era of intelligent, sustainable, and resilient chip production. As demand for advanced electronics accelerates, AI will play a critical role in shaping the future of the semiconductor ecosystem. Source: https://researchintelo.com/report/ai-in-semiconductor-manufacturing-market