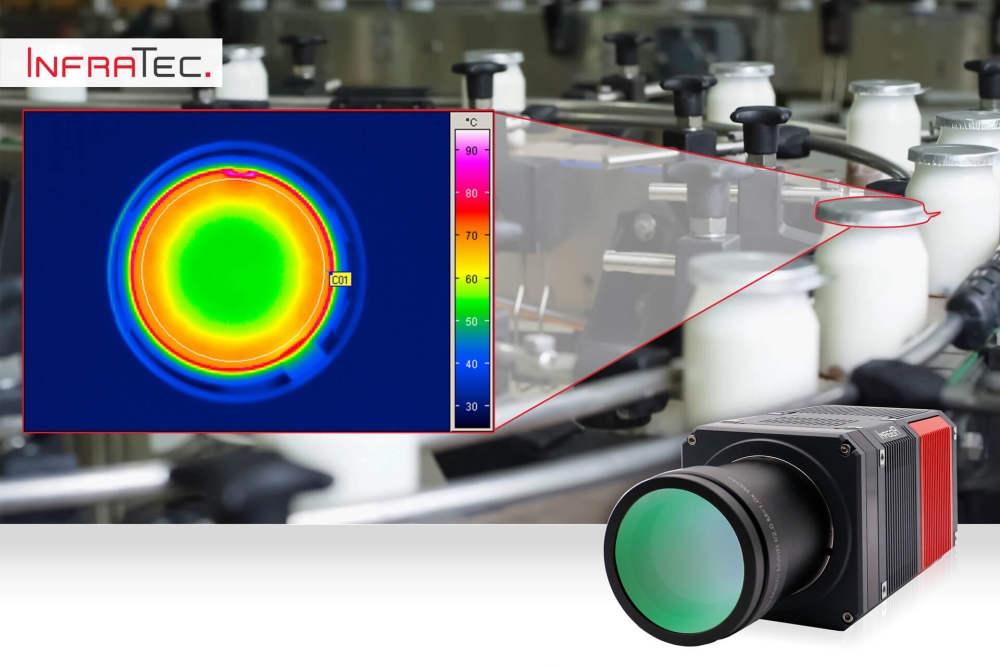

ImageIR 6300: Cooled Thermographic Camera for Continuous Industrial Operation

New MWIR System Camera from InfraTec Offers Top Performance at a Very Good Price-Performance Ratio

The radiometrically calibrated system camera ImageIR® 6300 is equipped with a cooled focal plane array photon detector of the latest generation. By combining the detector format of (640 × 512) IR pixels with the very small pixel pitch of 10 μm, the camera delivers razor-sharp images. Due to its snapshot mode, moving objects can also be displayed without distortion.

The innovative XBn detector technology allows the detector to be operated at a significantly higher working temperature than the usual approximately 80 K. This allows the size, weight and power (SWaP) of the integrated detector/cooler unit to be minimised. The service life of the implemented cooler can thus be significantly increased to about 18,000 hours. Using this technology, the power consumption, dimensions and weight of the ImageIR® 6300 have been significantly reduced and its maintenance-free service life has been considerably extended. These are key features that qualify the camera for use in OEM and continuous operation applications.

Its pixel pitch of only 10 μm gives the system camera a comparatively small pixel size. This allows a compact optical design while maintaining high image quality. In combination with radiometric calibration, most precise measurement results can be achieved. With an optionally available integrated solid state drive (SSD), large amounts of data can be stored directly on the camera.

Technical Refinements of the ImageIR® 6300

The ImageIR® 6300 is the first model in the ImageIR® series to feature a new integrated operating system. This opens a wide range of new functions, such as fully autonomous camera operation without the need for an additional control PC. The camera can also be controlled via a web interface using a smartphone or tablet. In addition, users can run their own software directly on the camera and access the data stream directly via the integrated SDK. Together with the option of power supply via a wide-range input (9–36 V) or Power over Ethernet (PoE), these features make the infrared camera much easier to use. This is particularly true for plant-integrated applications and in hard-to-reach places.

Measurements with the ImageIR® 6300 can be carried out at two speeds. In normal mode, the camera achieves full frame rates of up to 180 Hz. With the binning function, the frame rate can be increased by more than three times to up to 620 Hz. This is made possible by combining four detector pixels into a single one. Thereby the sensitive pixel area is increased to compensate for the shorter integration times, and the readout of the pixel data is accelerated. At the same time, the thermal resolution improves by a factor of two in high-speed mode.

Several other features of the ImageIR® series are also available for the new camera, such as the HighSense and Multi Integration Time functions for setting up individual measurement ranges or integration times and for flexible adaption to changing temperature measurement ranges or integration times.

A wide range of different interchangeable lenses (12 mm, 25 mm, 50 mm with optional 300 mm close-up, 1x microscope, 50 mm close-up) is available for the ImageIR® 6300. This allows the camera to be optimally configured for different applications, from inline inspection to laboratory testing.