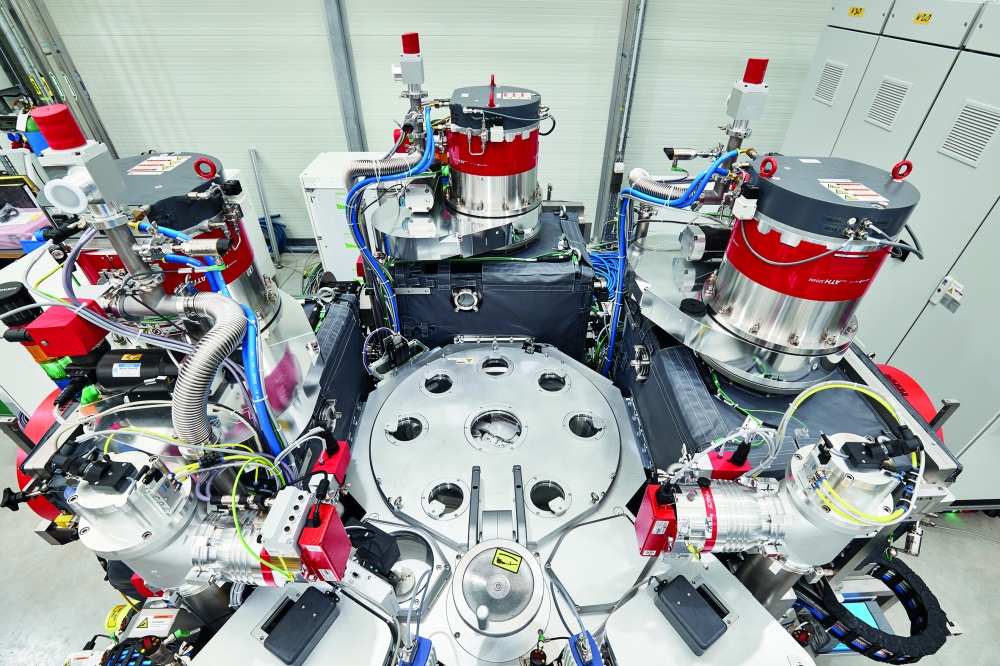

scia Systems provides thin-film processing breakthrough

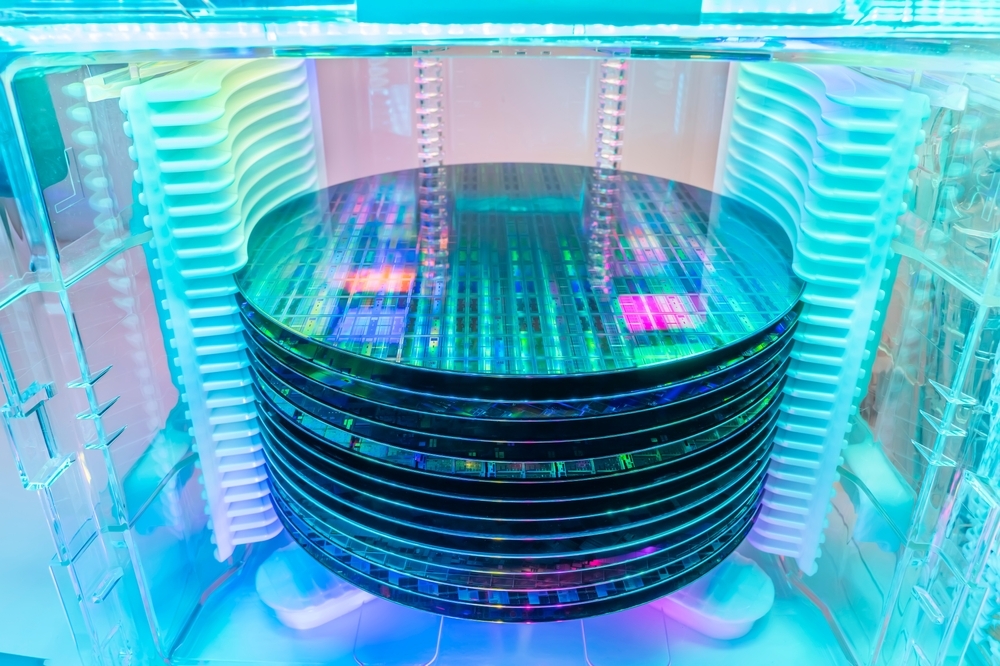

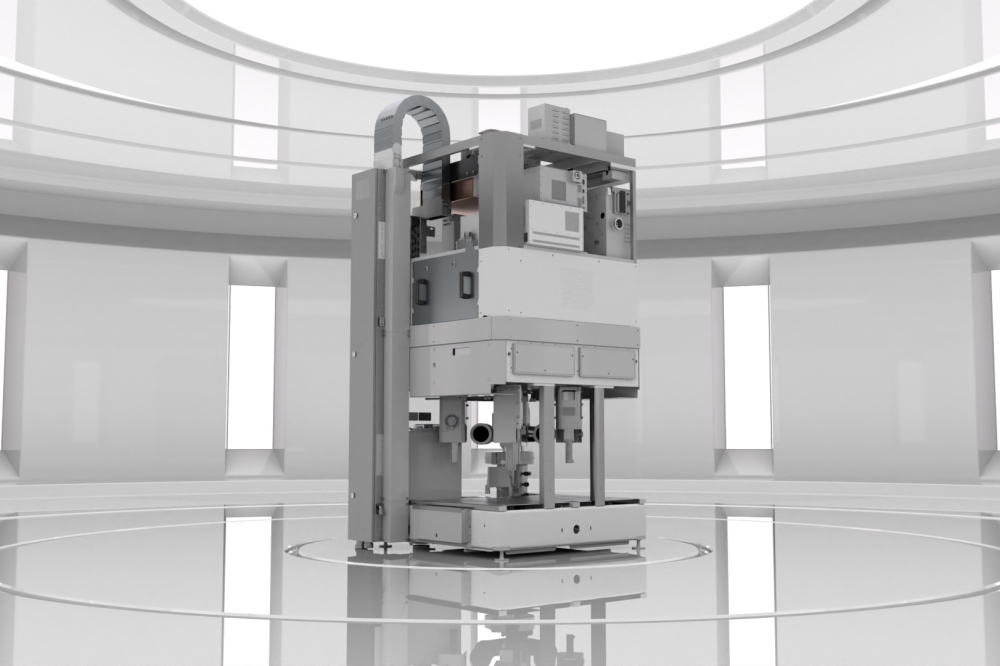

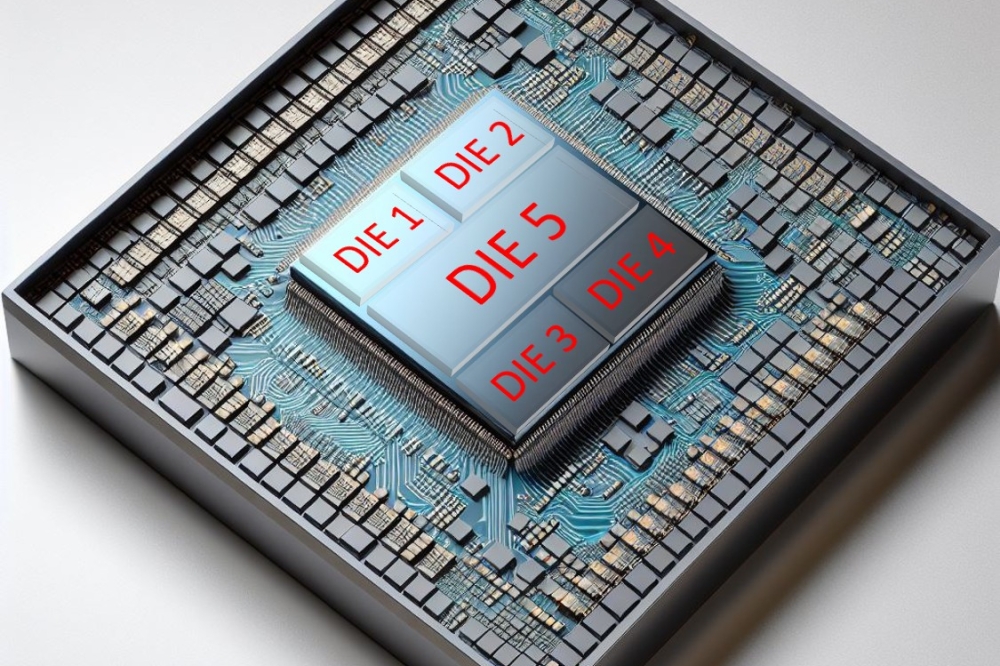

scia Systems has introduced its all-new cluster solution, the scia Cluster 200, a modular platform for coating, etching, and cleaning processes based on advanced ion beam and plasma technologies. The scia Cluster 200 uses multiple identical process chambers that can be combined to significantly increase throughput (up to 5X) or integrate different process technologies for sequential process steps on a single wafer without a vacuum break.

The scia Cluster 200 system can be configured individually according to the customer's application, allowing up to five process chambers and one or more load locks to be installed around the central transfer chamber. Available processes include the industry’s most comprehensive technology portfolio:

· Ion beam etching (IBE/RIBE/CAIBE)

· Ion beam trimming (IBT)

· Ion beam deposition (DIBS)

· Magnetron sputtering

· E-beam evaporation

· Atomic layer deposition (ALD)

· Plasma-enhanced CVD (PECVD)

· Reactive ion etching (RIE)

With this innovative cluster configuration, the scia Cluster 200 also provides a significantly reduced total cost of ownership (TCO) compared to an equivalent number of single-chamber process systems due to its smaller footprint, utility consumption, and logistics. scia Systems’ proven control software, used on all tools and 24/7 installations, provides uniform recipe management across all process modules and integrated measurement tools for best usability. By combining high throughput, precision, and process flexibility in a single platform, the scia Cluster 200 system is ideally suited for both R&D and mass production applications.

Single-process clusters to increase throughput

scia Systems offers cluster solutions for single-process systems, which are designed for high-volume, high-reliability production environments with critical uptime and throughput requirements. In this configuration, the substrates are processed in identical process chambers simultaneously, which guarantees a consistent quality and uniform process results.

Thanks to the new system’s modularity, it is easy to add additional chambers (up to five chambers in maximum configuration) with minimal effort to enable higher throughput. This ensures a future-proof production solution for manufacturers that fits into an intelligent and scalable production line and meets the growing demand for flexibility and scalability.

Furthermore, the cluster configuration enables continuous process improvement (CPI) by testing new process recipes in one chamber while maintaining continuous production in another.

Multi-process cluster systems for sequential process steps without a vacuum break

The scia Cluster 200 is also available as a multi-process cluster, which is ideal for multi-step processing required in high-precision manufacturing of next-generation devices. Various coating,

etching, and cleaning processes can be done sequentially in the same system with high consistency and increased efficiency. This ensures a faster turnaround time because there is no need for inter-system transfers, which reduces total process time.

Furthermore, the substrates move between processes without air exposure, preserving surface quality and helping to avoid contamination and oxidation.

Thanks to the system’s modularity, chambers can be changed or upgraded for tailored configurations.

A variety of module combinations offers unprecedented flexibility in application areas

Besides state-of-the-art ion beam and plasma processes in MEMS and optical manufacturing, the scia Cluster 200 can be used to produce next-generation devices. Examples include: making Josephson Junctions from superconducting materials separated by a thin insulating barrier for quantum devices; fabricating three-dimensional optoelectronic microstructures for PICs, such as waveguides and other optical components; and producing photomasks and masters for nanoimprint lithography.