Sono-Tek to showcase SPT200 with wafer handling system

Attendees are invited to visit Booth 6280 to explore Sono-Tek’s advanced coating technologies for semiconductor manufacturing, including enhanced wafer handling and an early look at 300mm system expansion.

Featured Technologies at SEMICON West 2025:

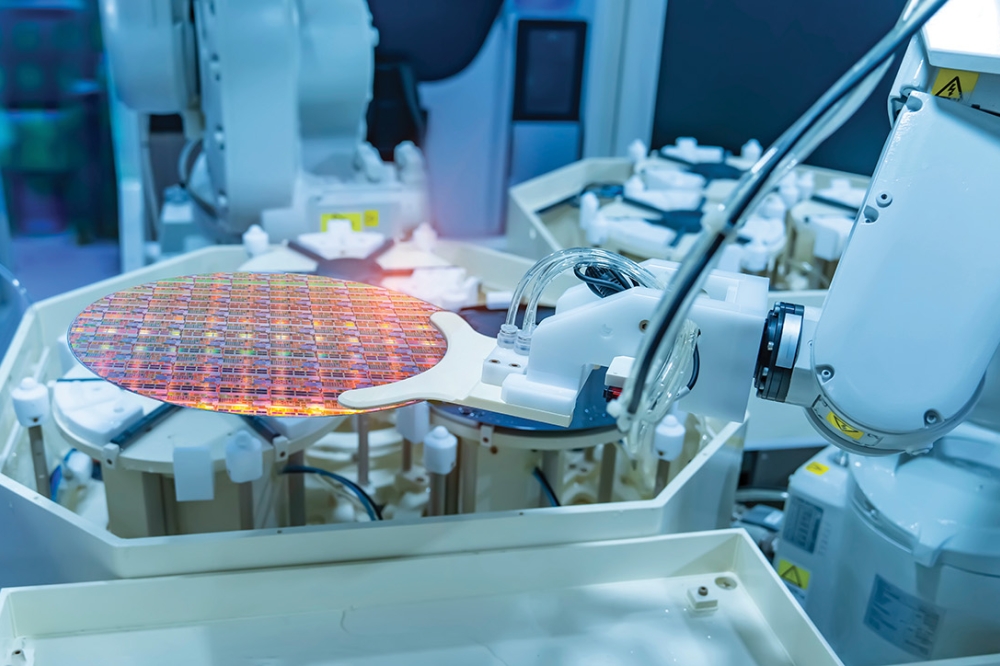

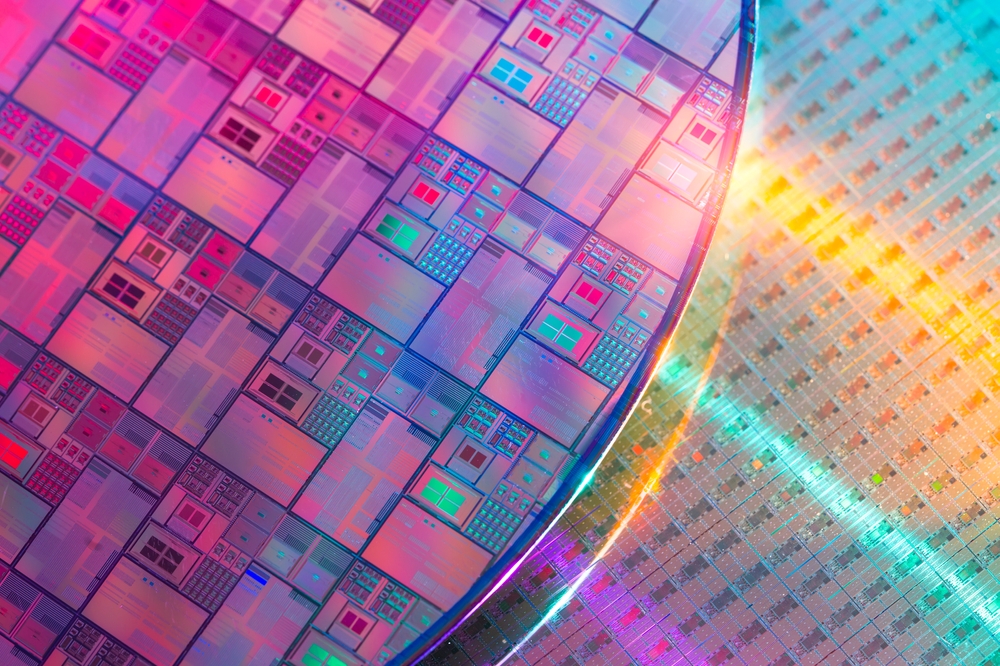

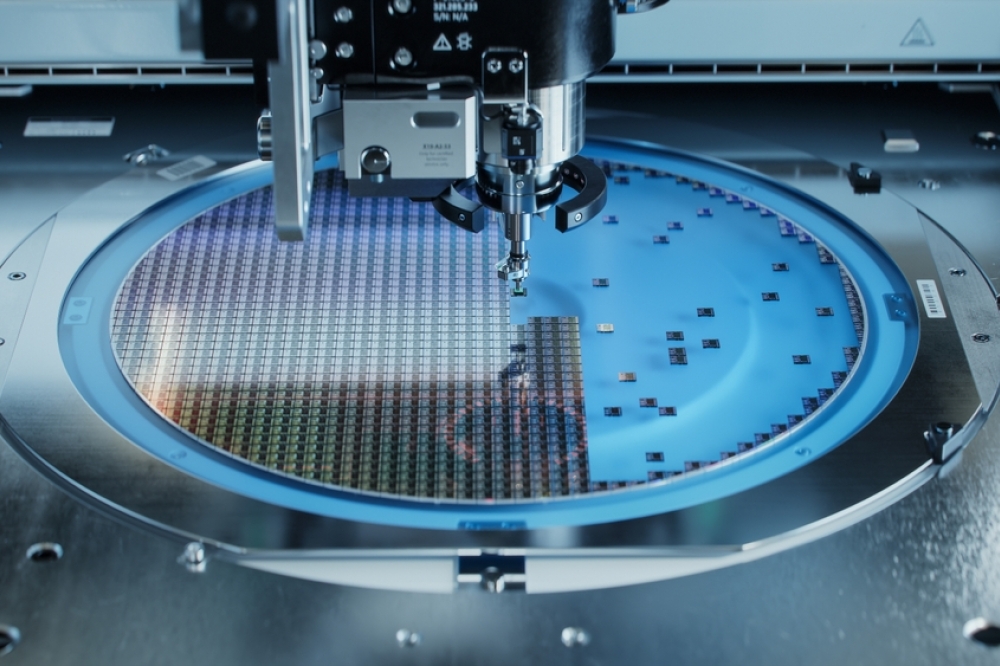

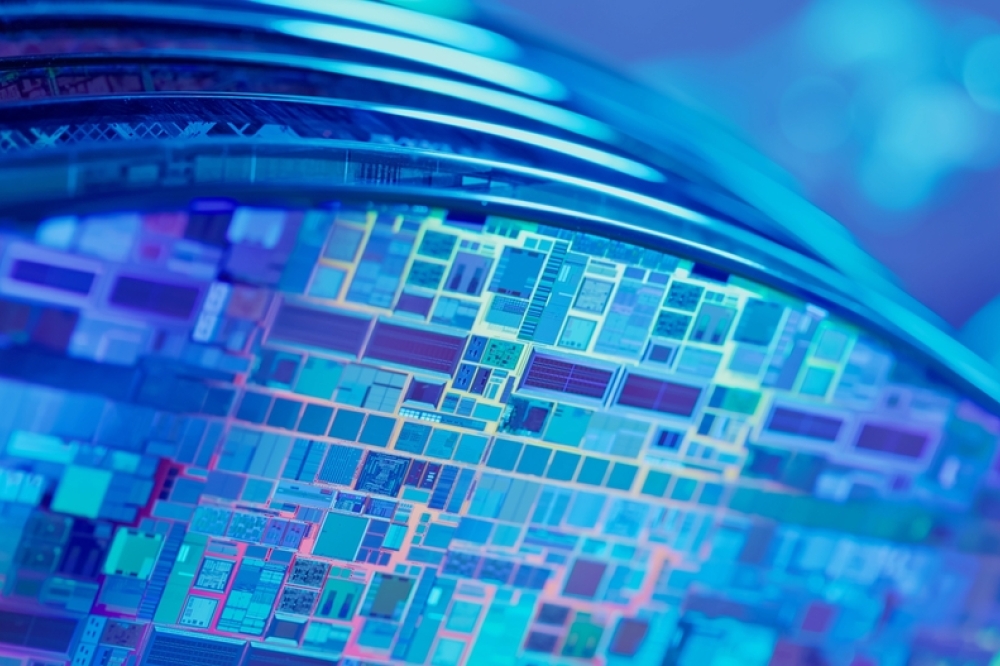

SPT200 Photoresist Coating System with Wafer Handler The SPT200 delivers uniform, repeatable photoresist coatings on challenging MEMs and high-aspect-ratio topographies using ultrasonic atomization. Designed for 100mm to 200mm wafers, the system ensures highly controlled droplet formation for optimal thin-film coverage.

The integrated Wafer Handling System, currently supporting 4–8" wafers, provides full automation to increase throughput and minimize operator intervention. A new project to expand support to 300mm (12-inch) wafers is underway and will be previewed during the event.

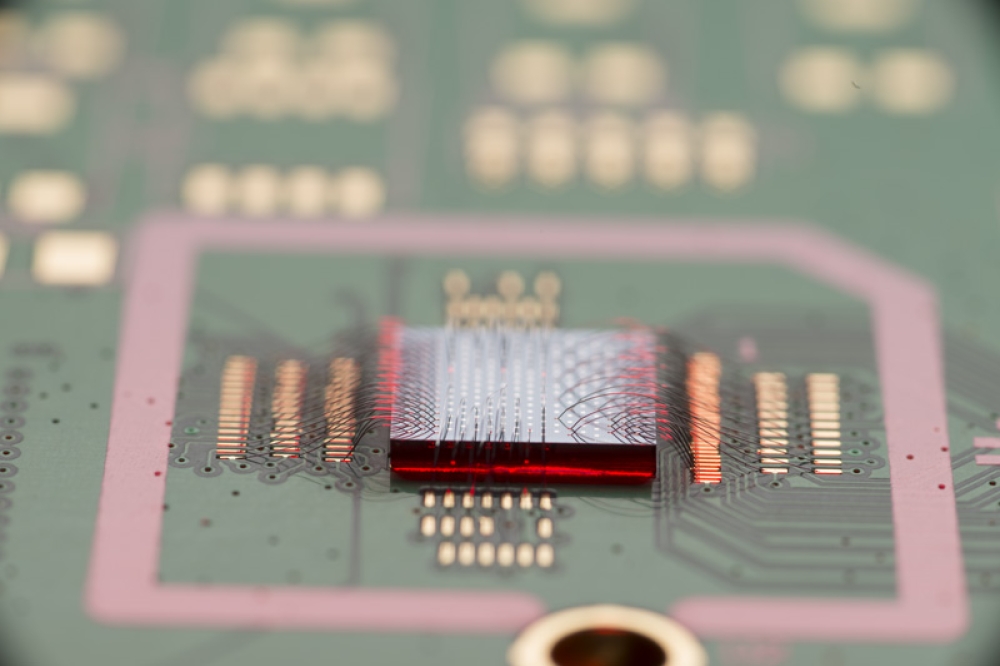

FlexiCoat System for EMI Shielding Sono-Tek’s FlexiCoat system offers a cost-effective, reliable alternative to sputtering for EMI shielding at the packaging level. Using ultrasonic spray nozzles, the system achieves precise, clog-free coatings over complex geometries with minimal overspray and high material transfer efficiency.

Additional Applications on Display:

· Polyimide and Protective Coatings for dicing and wafer-level packaging

· Flux Dispensing for flip chip and advanced interconnect assemblies

· Thin Film Deposition for displays and solar, including TCOs, CNTs, OPVs, AR coatings, and perovskites

Visit Booth 6280 to learn how Sono-Tek’s ultrasonic spray coating technologies are enabling greater efficiency, precision, and scalability semiconductor manufacturing.