Deep RIE Technology To Boom In MEMS, DRAM And Packaging

DRIE is becoming increasingly popular. Deep Reactive

Ion Etching (DRIE) is a structuration process which was originally used for

MEMS.

This process enables you to etch hundreds of microns in depth with almost vertical sidewalls with a very high aspect ratio. This can be up to over 50:1 in some cases.

The technology was first developed by Robert Bosch for MEMS, which require these features. But it is also used to excavate trenches for high-density capacitors for DRAM and more recently for creating Through Silicon Vias (TSVs) in advanced 3D wafer level packaging technology.

Equipment manufacturer Sumitomo Precision Products (SPP), obtained a license from Bosch to exploit this technology.

Yolé Developpement says this agreement has led to

incredible growth of the DRIE market. First used for production of

accelerometers, the process is now employed for production of some ink

jet-heads, pressure sensors, gyroscopes, micro phones and micro actuators, for

example, MEMS auto-focus.

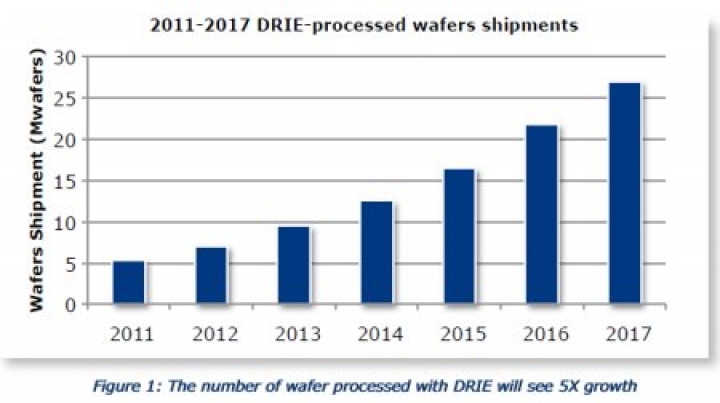

From 2011 to 2017, the number of DRIE-processed wafers is expected to shoot up from 5.4 million to more than 27 million when considering all wafer sizes. This is over 30% CAGR as shown in the figure above.

Competition is strengthening as applications are burgeoning.

Continuous growth for MEMS accelerometers was observed

in 2011. Although the device price pressure is very important in smartphones,

further penetration on feature-phones was observed and new markets appeared,

such as tablets.

What's more, the market for consumer gyroscopes sky-rocketed

in 2011. Indeed most handset OEMs adopted gyroscopes for their flagship

smartphones or tablets.

A new report by Yolé Developpement says 3-axis

gyroscopes will be the hottest MEMS product in the coming years as the

penetration of gyroscopes will keep increasing. Today, most of the inertial

MEMS have a comb-drive structure. Therefore, DRIE needs to be used for

micromachining.

From 2014, combo sensor integration (an integrated device incorporating several inertial sensors) will be largely adopted. This will drive the growth of DRIE for inertial MEMS. The year 2012 is also expected to see new MEMS devices that will also use DRIE. These include MEMS-based compact auto-focus products, offering quicker actuation, lower power consumption and better image quality.

More news articles