Novel Wafer-Scale CMOS Developments Boost X-Ray Imaging

A highly innovative high-resolution wafer-scale digital image

sensor that targets medical imaging applications has been developed at the Science

and Technology Facilities Council's (STFC) Rutherford Appleton Laboratory

(RAL).

One of the key aspects in the development of this CMOS imaging sensor by the STFC's CMOS Sensor Design Group, was the use of advanced analogue tools from Tanner EDA, a leading provider of tools for the design, layout and verification of analogue and mixed-signal integrated circuits (ICs).

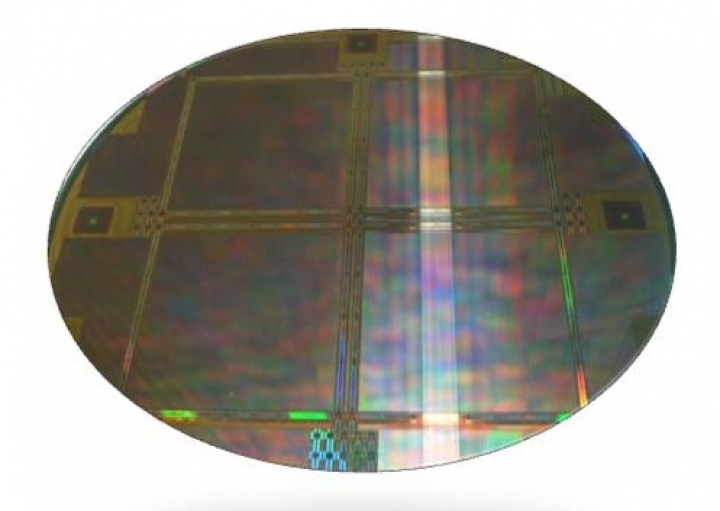

Measuring 120 x 145 mm and effectively using an entire 200 mm silicon wafer in its production, the new image sensor is being manufactured by TowerJazz, a global specialty semiconductor foundry, using its special CMOS sensor process technology.

The primary target application for the new sensor is X-ray medical imaging and more specifically mammography and digital tomosynthesis, the advanced diagnostic technique used to generate 3D representations of patients or other scanned objects. There is increasing interest in the use of solid-state-based X-ray detection systems in the replacement of conventional diagnostic imaging techniques.

One of these technologies is CMOS sensor based imaging, which can bring key advantages in terms of performance such as high resolution, high dynamic range and low noise capabilities. In addition, it can offer significant system cost advantages for X-ray imaging applications, although it can come with an initial penalty in terms of design complexity in the actual development of the CMOS sensor.

As no lens is used in CMOS-imaging-based X-ray applications, the size of an image sensor has to match the size of the target area. While in some medical imaging applications such as extra-oral panoramic dental imaging, a sensor measuring 139 x 120 mm is usually adequate. However, this is not big enough for most medical applications. For example, mammography applications require a sensor that is approximately 290 x 240 mm in size, and even larger for chest radiography. In other applications such as full body scanning for security purposes, an even more extensive sensor area can be necessary.

The new STFC high-resolution and radiation-hard CMOS sensor has been developed to meet these challenges. A unique feature of the device is that it has sensing pixels right up to the edges on three sides of the imager. This allows multiple sensors, manufactured on cost-effective 200 mm silicon wafers, to be "˜butted' or "˜tiled' together in a 2 x 2 arrangement to form a significantly larger imaging area and to meet the requirements for mammography applications. Additionally, any 2 x N sensor arrangements are possible, thus making the device ideal for applications that demand even larger area coverage, such as chest imaging or security scans.

Conventional CMOS imagers have the required electronic circuitry implemented on two sides of an imaging array to address the individual sensor pixels. To achieve this three-side "˜buttable' design, the STFC CMOS Sensor Design Group developed some innovative electronic circuitry IP (Intellectual Property) to implement the necessary pixel readout and row-addressing driver functions on just one edge of each sensor, with extra circuitry embedded in the actual pixel array, while maintaining a high degree of image quality.

The full-custom-design sensor, which offers a focal plane of 139.2 x 120 mm, has 6.7 million (2800 x 2400) pixels on a 50µm pitch, 32 analogue outputs and also features low noise, a high dynamic range and a programmable region-of-interest readout. Each pixel is constructed from a basic three-transistor (3T) base with a low-noise partially pinned photodiode, offering "˜charge-binning' capability to deliver its high signal-to-noise characteristics.

This means the sensor can offer a very high frame rate of 40 frames per second at full resolution and "˜binned' images can be read at an increasingly faster rate. The high frame rate makes the sensor ideal for applications that demand fast acquisition of multiple images such as in digital tomosynthesis, which is receiving increasing interest in the medical field.

The STFC CMOS Sensor Design Group worked with Tanner EDA and its exclusive representative in Europe, EDA Solutions, to use the Tanner tools to develop the innovative pixel-addressing IP, which was almost entirely analogue circuitry with only a small amount of on-chip digital logic.

In particular, the STFC design group used Tanner Tools Pro, in conjunction with Tanner's HiPer Verify tool. Tanner Tools Pro is a comprehensive software suite for the design, layout and verification of analogue, mixed-signal, RF and MEMS ICs. The tool suite comprises fully integrated front-end and back-end tools including schematic capture, circuit simulation, waveform probing, physical layout and verification. Tanner's HiPer Verify is a comprehensive and affordable solution for analogue and mixed-signal IC design rule checking (DRC) and hierarchical netlist extraction.

The STFC design group also worked closely with TowerJazz for the manufacture of the sensor, which is implemented in a 180/350nm dual-gate CMOS Image Sensor (CIS) process technology on 200mm wafers. TowerJazz's CIS technology process enables the customisation of pixels, according to project needs for many digital imaging applications, offering excellent dark current, low noise and dynamic range performance characteristics.

"The STFC works closely with its partners, such as Tanner EDA and TowerJazz, to develop innovative solutions that meet highly demanding requirements in a range of scientific and industrial applications," said Dr. Renato Turchetta, CMOS Sensor Design Group Leader at the Science and Technology Facilities Council's Rutherford Appleton Laboratory.

"The complete set of Tanner EDA tools was extremely well suited for the design of this sensor with its complex analogue architecture. This, in conjunction with the high yield of the TowerJazz CMOS Image Sensor process technology, was instrumental in achieving a first-right-time design with no prerequisite for any initial prototype design."