Silicon anodes promise better batteries

US researchers have developed a new method to fabricate several high-performance anodes from a single silicon wafer.

The process uses porous silicon to replace graphite as an element in rechargeable lithium-ion batteries, laying the groundwork for longer-lasting, more powerful batteries for commercial electronics and electric vehicles.

Silicon holds great promise as an anode material in lithium ion batteries, thanks to its large specific capacity for lithium.

Previous research carried out by Professor Sibani Lisa Biswal and colleagues at Rice University and Lockheed Martin revealed that porous silicon can soak up to ten times more lithium than the usual anode material, graphite, as the silicon expands to absorb the lithium ions.

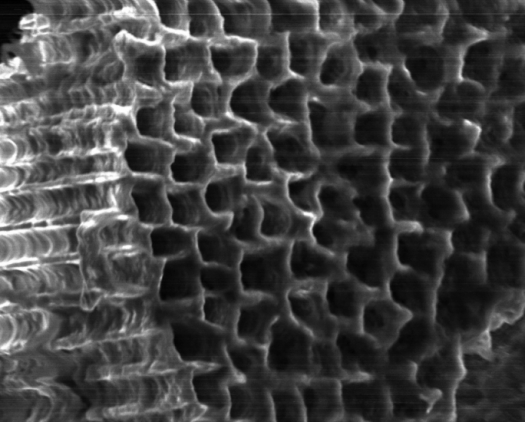

With this in mind, Biswal and researchers have developed a novel "lift-off" process in which a free-standing macroporous silicon film, or "silicon sponge" is electro-chemically detached from an underlying silicon wafer. The film is then soaked in a conductive polymer binder, pyrolysed polyacrylonitrile to enhance its conductivity.

"At least four films can be drawn from a standard 250-micron-thick wafer, and the substrate can be reused to make more sponges," explains Biswal.

According to the researcher, attaching the films to a cathode current collector - in this case, a thin layer of titanium on copper - and placing in a battery configuration gives a working lithium-ion battery.

The team is now investigating techniques to increase the number of charge-discharge cycles, a critical feature for commercial applications in which rechargeable batteries are expected to last for years.