Self-calibrating MEMS promise more accurate measurements

US researchers have demonstrated MEMS that could lead to extremely accurate sensors and motors

Purdue University, US, researchers have developed a self-calibrating micro-electromechanical system that paves the way to accurate sensors and motors that could be used in lithography to create next-generation computer circuits.

While MEMS are already in commercial use, this new device is the first of its kind that can calibrate itself, a step that is critical in high accuracy applications.

"Self-calibration is needed as each MEMS device is slightly different, due to manufacturing variations," says Professor Jason Vaughn Clark from computer and mechanical engineering at Purdue University. "Variations in geometry, stiffness and mass can significantly affect performance... and no two MEMS behave identically."

"Since conventional methods to measure MEMS properties are usually impractical, expensive, have unknown accuracy and large uncertainty, enabling MEMS to calibrate themselves is a game-changing innovation," he adds.

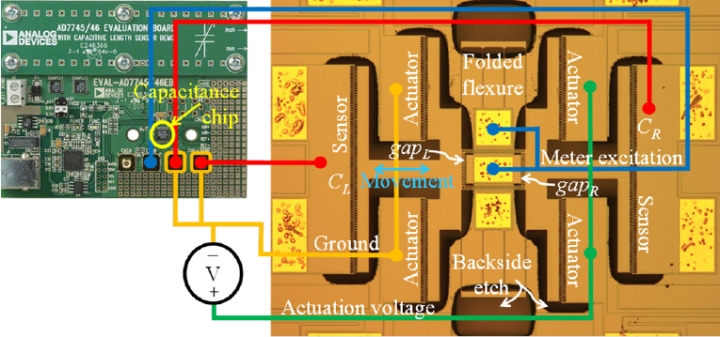

The devices contain two opposing comb drives - comb-shaped linear motors - that are drawn together when a voltage is applied and then return to their original position when the voltage is turned off.

"We apply enough voltage to close two unequal gaps and measure the resulting changes in capacitance," he says. "We use this measurement to determine the geometrical difference between layout and fabrication... and once you have this measurement you have calibrated the device."

The capacitance measurements can be used to calculate other properties such as displacement, force, stiffness and mass, and as Clark highlights, existing MEMS designs with comb drives can easily be modified to become self-calibrating.

"Accurate metrology is a problem that has eluded researchers since the beginning of MEMS and nano-technology in the late 1980s," he says. "But now, using a $15 chip that you can fit on your fingertip, we have a technology that is able to measure MEMS displacements better than a $500,000 electron microscope."

Clark and his team now intend to use their self-calibrating MEMS to boost the accuracy of atomic force microscopes at the university and build more accurate gravity meters for detecting underground petroleum reserves.