Commercialising Lab On A Chip Technology

Lab on a chip (LOC) devices are envisioned to one day revolutionise how laboratory tasks such as diagnosing diseases and investigating forensic evidence are performed.

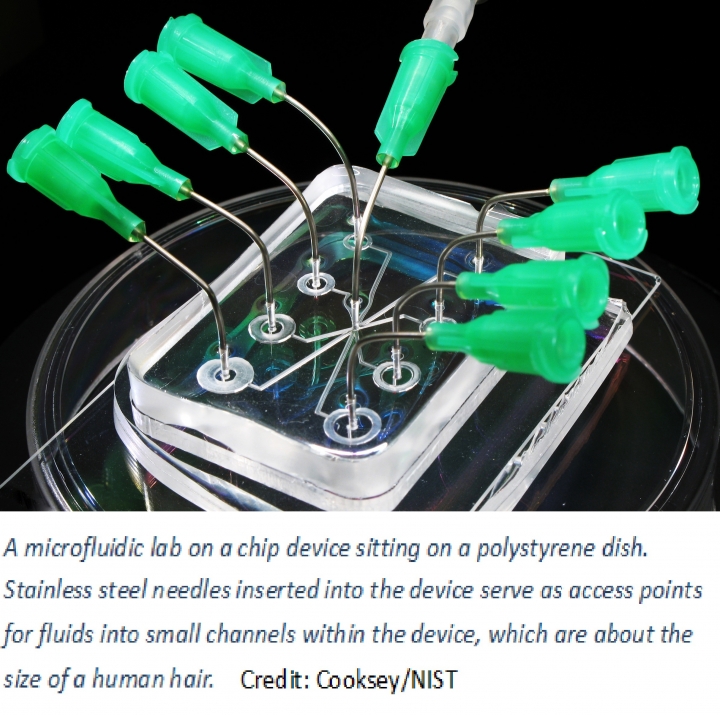

LOC devices are microchip-size systems that can prepare and analyse tiny fluid samples with volumes ranging from a few microlitres (millionth of a litre) to sub-nanolitres (less than a billionth of a litre).

They are a subset of MEMS devices and sometimes referred to as "Micro Total Analysis Systems" (µTAS). Microfluidics is a broader term that describes also mechanical flow control devices like pumps and valves or sensors like flowmeters and viscometers. However, "Lab-on-a-Chip" in general indicates the scaling of single or multiple lab processes down to chip-format. "µTAS" on the other hand refers to the integration of the total sequence of lab processes in order to perform chemical analysis.

However, a recent paper from the National Institute of Standards and Technology (NIST) argues that before LOC technology can be fully commercialised, testing standards need to be developed and implemented.

"A testing standard," explains NIST physical scientist and paper author Samuel Stavis, "defines the procedures used to determine if a lab on a chip device, and the materials from which it is made, conform to specifications."

Standardised testing and measurement methods, Stavis points out, will enable MEMS systems LOC manufacturers at all stages of production. These range from the processing of raw materials to final rollout of products, to accurately determine important physical characteristics of LOC devices such as dimensions, electrical surface properties, and fluid flow rates and temperatures.

To make his case for testing standards, Stavis focuses on autofluorescence, the background fluorescent glow of an LOC device that can interfere with the analysis of a sample.

Stavis points out that multiple factors must be considered in the development of a testing standard for autofluorescence, including: the materials used in the device, the measurement methods used to test the device and how the measurements are interpreted. "All of these factors must be rigorously controlled for, or appropriately excluded from, a meaningful measurement of autofluorescence," according to Stavis.

Quality control during LOC device manufacturing, he stresses, may require different tests of autofluorescence throughout the process. "There may be one measure of autofluorescence from the block of plastic that is the base material for a chip, another once the block has been fashioned into the substrate in which the functional components are embedded, and yet another as the final device is completed," Stavis says. "To manufacture lab on a chip devices with reliably low autofluorescence, accurate measurements may be needed at each stage."

Stavis also emphasises that it is important not to confuse testing standards with product standards, and to understand how the former facilitates the latter. "A product standard specifies the technical requirements for a lab on a chip device to be rated as top quality," he says. "A testing standard is needed to measure those specifications, as well as to make fair comparisons between competing products."