News Article

Recycling Waste Silicon Into Anodes For LI Batteries

Researchers at Rice University and the Université catholique de Louvain,

Belgium, have developed a way to make flexible components for rechargeable

lithium-ion (LI) batteries from discarded silicon.

The research at Rice was led by Pulickel Ajayan, Rice's M. and Mary

Greenwood Anderson Professor in Mechanical Engineering and Materials

Science. The scientists in the Rice lab created forests of nanowires from

high-quality but hard-to-recycle silicon.

Silicon absorbs ten times more lithium than the carbon commonly used in LI

batteries, but because it expands and contracts as it charges and discharges, it

breaks down quickly.

Earlier this month, a paper describing the work was published in the journal,

Proceedings of the National Academy of Science 2012. In the paper, the

technique used by the scientists to make carefully arrayed nanowires encased

in electrically conducting copper and ion-conducting polymer electrolyte into an

anode, is described.

The material gives nanowires the space to grow and shrink as needed, which

prolongs their usefulness. The electrolyte also serves as an efficient spacer

between the anode and cathode.

The first step the researchers took was to pull multiple layers of the anode/

electrolyte composite from a single discarded wafer. Samples of the material

made at Rice look like strips of white tape or bandages as depicted in the

figure below.

Rice University research scientist Arava Leela Mohana Reddy holds strip of anode

material and a piece of waste silicon (left). (Credit: Jeff Fitlow / Rice University)

Following this, colloidal nanosphere lithography, was used to make a silicon

corrosion mask by spreading polystyrene beads suspended in liquid onto a

silicon wafer. The beads on the wafer self-assembled into a hexagonal grid

and stayed put when shrunken chemically.

A thin layer of gold was then sprayed on and the polystyrene was removed. This

left a fine gold mask with evenly spaced holes on top of the wafer. "We could do

this on wafers the size of a pizza in no time," says Vlad.

The mask was used in metal-assisted chemical etching, where the silicon

dissolved in the regions where it was in contact with the metal. Over time in a

chemical bath, the metal catalyst sank into the silicon leaving millions of evenly

spaced nanowires, 50 to 70 µm long, poking through the holes, as shown below.

Silicon nanowires poke through a gold mask on their way to becoming part of a lithium ion battery

Left: Magnification is x6000 Right: Magnification is x50000

(Credit: Alexandru Vlad/Rice University)

The researchers then deposited a thin layer of copper on the nanowires to

improve their ability to absorb lithium and then infused the array with an

electrolyte that not only transported ions to the nanowires but also served as a

separator between the anode and a later-applied cathode.

"Etching is not a new process," points out Reddy, a co-author of the paper. "But

the bottleneck for battery applications had always been taking nanowires off the

silicon wafer because pure, free-standing nanowires quickly crumble."

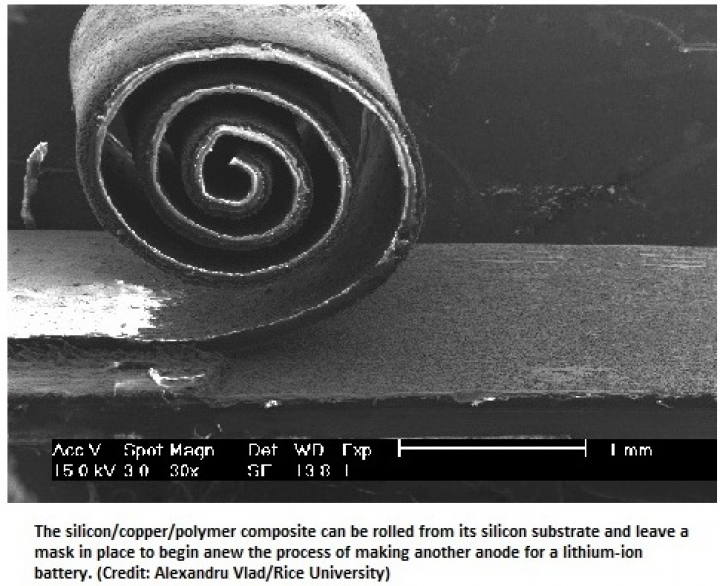

But in the new process, the electrolyte engulfs the nanowire array in a flexible

matrix and facilitates its easy removal. "We just touch it with the razor blade and

it peels right off," Reddy adds. The mask is left on the unperturbed wafer to etch

a new anode. When combined with a spray-on current collector on one side and

a cathode and current collector on the other, the resulting battery showed

promise as it delivered 150 milliamp hours per gram with little decay over 50

charge/discharge cycles.

The researchers are working to enhance those qualities and testing the anodes

in standard battery configurations. The scientists hope their devices are a step

toward a new generation of flexible, efficient, inexpensive batteries that can

conform to any shape. Also, according to Ajayan, transforming waste into

batteries should be a scalable process.

"The novelty of the approach lies in its inherent simplicity. We hope the present

process will provide a solution for electronics waste management by allowing a

new lease on life for silicon chips," Reddy concludes.

Further details of this work have been detailed in the paper, "Roll up nanowire

battery from silicon chips," by Alexandru Vlada et al, in Proceedings of the

National Academy of Science 2012, published ahead of print on September 4th,

2012. DOI:10.1073/pnas.1208638109

The Army Research Office supported research at Rice University. The National

Scientific Research Foundation, the Special Research Fund, the TINTIN project

"“ ARC, the French Community of Belgium, the Fund for Scientific Research

and the Wallonne Region (Programme ERABLE) supported research in Belgium.