News Article

How IBM & GLOBALFOUNDRIES Improve Computer Chips

A refined method developed at the National Institute of Standards and Technology (NIST) for measuring nanometre-sized objects may help computer manufacturers more effectively size up the myriad tiny switches packed onto chips' surfaces.

The process, which makes use of multiple measuring instruments and statistical techniques, is already drawing attention from the semiconductor industry.

According to NIST scientist Richard Silver, "IBM and GLOBALFOUNDRIES have already begun developing the technique since we first described it at a 2009 conference, and they are improving their measurements using this hybrid approach."

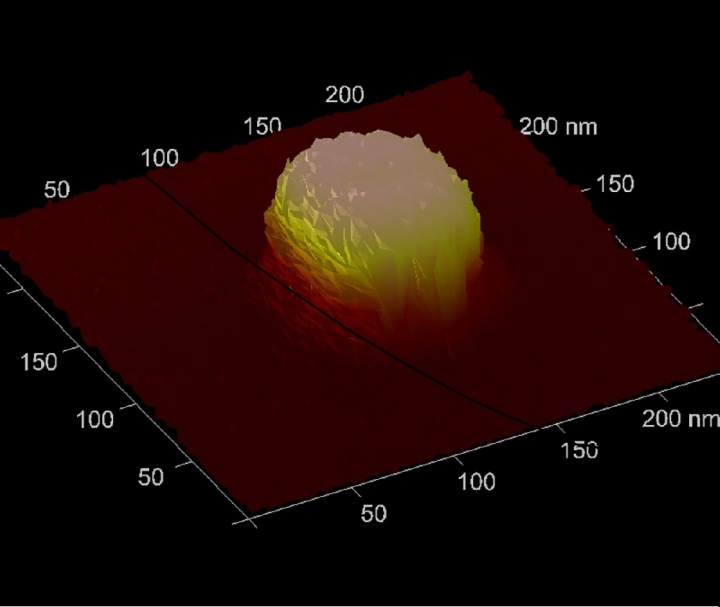

The image above, showing a tiny silicon pillar measuring less than 100 nm along any of its sides, is the sort of computer chip feature that manufacturers can now measure more precisely with NIST's hybrid metrology method. This information can reduce the nagging uncertainties that have long plagued industry's measurement efforts.

Nothing in life is certain except maybe death and taxes, but in the world of computer chip manufacturing, uncertainty is a particularly annoying issue, especially when measuring features smaller than a few dozen nanometres. Precision and accuracy are essential to controlling a complex and expensive manufacturing process to ensure the final chips actually work.

But features on modern chips are so tiny that optical microscopes cannot make them out directly. Metrologists have to use indirect methods, like "scatterometry" to deduce their shape from sampling the pattern light creates as it scatters off the features' edges. When this isn't enough, there's atomic force microscopy (AFM). It's expensive and slow, but it can give distinct measurements of the height and width of a nanoscale object while light scattering occasionally has trouble distinguishing between them.

Even with these measurement techniques, however, there's always a nagging margin of error. "Maybe scatterometry tells you the width of an object is 40 nanometres, but it's plus or minus three nanometres, a relatively large variance," says NIST scientist Richard Silver. "Making things worse, the total uncertainty usually increases when measurement techniques are combined, making our vision even hazier."

What the NIST team needed was a more precise yet less expensive method of measuring what sits on a chip, and their answer has turned out to be a combination of scanning techniques and statistical analysis. They first created a library of simulated data based on typical chip feature dimensions to which they can compare their actual measurements, made with AFM, scatterometry and other means.

A complex statistical analysis of library values is then compared with actual measurements to extract valid measurement values, but this is often at a cost of high uncertainty. But NIST statistician Nien Fan Zhang found an elegant way to use a statistical method called Bayesian analysis to incorporate a few key additional measured values from other tools into the library model before performing the comparison.

In doing so, the team was able to reduce the uncertainty in some of the measurements, lowering them by more than a factor of three in some cases. This approach is expected to be essential when measuring complex three-dimensional transistors 16 nm in size or smaller in the near future.

The math wizardry is a little counter-intuitive. "In essence, if you've got a really small uncertainty in your AFM measurement but a big one in your optical measurements, the final uncertainty will end up even smaller than either of them," says Silver.

The hybrid method has been described in detail in the paper, "Improving optical measurement uncertainty with combined multitool metrology using a Bayesian approach," by N.F. Zhang et al, in Applied Optics, Vol. 51, No. 25. Sept. 1, 2012. DOI: http://dx.doi.org/10.1364/AO.51.006196