Solution To Machining Semiconductors

A process developed by µ-LAM may eliminate the need for multiple sequential procedures, such as grinding, lapping and polishing

µ-LAM has introduced a process which it says provides an effective technique for machining nominally hard and brittle semiconductor materials, without fracture.

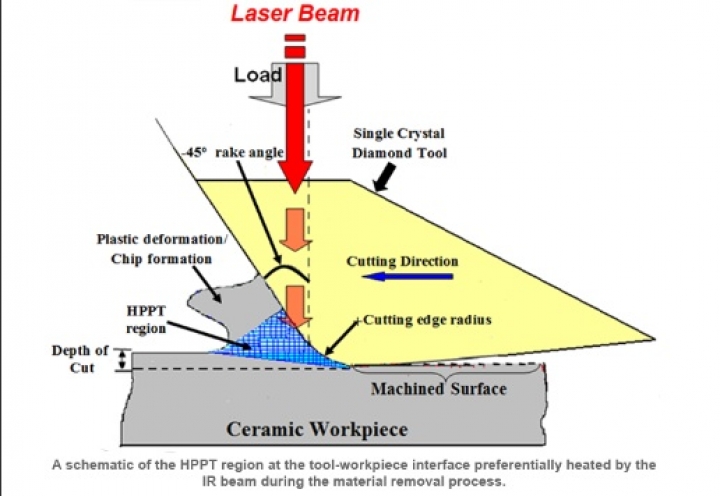

The process uses a combination of generating a ductile high pressure phase (via the HPPT) and then heating and thermally softening the transformed material with the laser energy. This results in a more ductile/pliable (plastic) and less brittle material.

The firm says not only can fracture free surfaces (free of subsurface cracks also) be generated, but other surface and subsurface damage can be minimised or eliminated altogether.

Competing technologies and processes such as traditional single point diamond turning (SPDT), grinding, lapping and polishing all entail some deficiencies that µ-LAM says its process overcomes. These include reduced tool wear (as a result of the softer material response due to the laser heating), and reduced brittleness (also a result of laser heating).

Less machining is another advantage due to induced brittle fracture which is typically associated with grinding, increased form accuracy (compared to grinding, lapping or polishing), shorter overall processing times and thus increased productivity. µ-LAM says its process has the potential to displace multiple sequential processes, such as grinding, lapping and polishing.

µ-LAM also believes another promising side benefit of the laser heating associated with its process is that a healing, annealing or recrystallisation occurs in-situ during the actual machining process.