Black Silicon Solar Cell Efficiency Doubled

Unlike standard silicon solar cells, black silicon absorbs nearly all of the sunlight that hits it, including infrared radiation, and converts it into electricity

Solar cells convert three-quarters of the energy contained in the sun"˜s spectrum into electricity, yet the infrared spectrum is entirely lost in standard solar cells.

In contrast, black silicon solar cells are specifically designed to absorb this part of the sun"˜s spectrum . And researchers have recently succeeded in doubling their overall efficiency.

Another company has previously explored this technology, but not in the solar market. SiOnyx, an innovator in advanced imaging systems,earlier this year, made a strategic investment and technology development agreement with In-Q-Tel (IQT). Together the collaborators aim to accelerate the integration of what is its proprietary "Black Silicon" technology into image sensors in imaging systems.

The sun blazes down from a deep blue sky, and rooftop solar cells convert this solar energy into electricity. But not all of it. Around a quarter of the sun's spectrum is made up of infrared radiation which cannot be converted by standard solar cells, so this heat radiation is lost.

One way to overcome this is to use black silicon. This material absorbs nearly all of the sunlight that hits it, including infrared radiation, and converts it into electricity.

But how is this material produced?

"Black silicon is produced by irradiating standard silicon with femtosecond laser pulses under a sulphur containing atmosphere," explains Stefan Kontermann, who heads the Research group "Nanomaterials for Energy Conversion." The project is part of the Fraunhofer Project Group for Fibre Optical Sensor Systems at the Fraunhofer Institute for Telecommunications, Heinrich-Hertz-Institut, HHI.

"This structures the surface and integrates sulphur atoms into the silicon lattice, making the treated material appear black." If manufacturers were to equip their solar cells with this black silicon, it would significantly boost the cells' efficiency by enabling them to utilise the full sun spectrum.

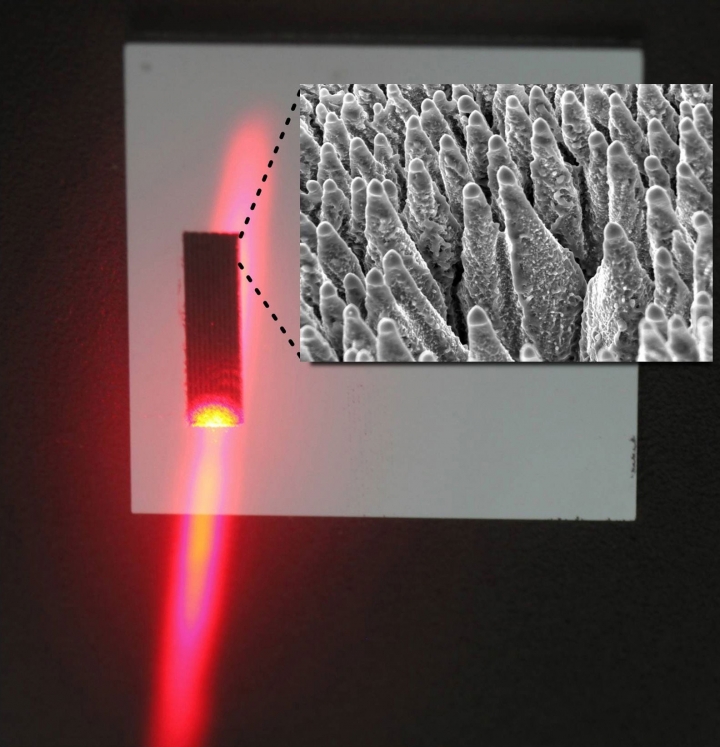

The image above shows black silicon being irradiated with a laser. The smaller image is a scanning electron image of the black silicon.

Researchers at HHI have now managed to double the efficiency of black silicon solar cells. In other words, they have created cells that can produce more electricity from the infrared spectrum. "We achieved that by modifying the shape of the laser pulse we use to irradiate the silicon," says Kontermann.

This enabled the scientists to solve a key problem of black silicon. In normal silicon, infrared light does not have enough energy to excite the electrons into the conduction band and convert them into electricity, but the sulphur incorporated in black silicon forms a kind of intermediate level.

You could compare this to climbing a wall. The first time you fail because the wall is too high, but the second time you succeed in two steps by using an intermediate level. However, in sulphur this intermediate level not only enables electrons to climb the "˜wall', it also works in reverse, enabling electrons from the conduction band to jump back via this intermediate level, which causes electricity to be lost once again.

By modifying the laser pulse that drives the sulphur atoms into the atomic lattice, researchers can change the positions that these atoms adopt in the lattice and change the height of their "˜levels', in other words their energy level. "We used the laser pulses to alter the embedded sulphur in order to maximize the number of electrons that can climb up while minimising the number that can go back down," Kontermann sums up.

In the first stage of the project, the scientists modified the laser pulses and investigated how this changed the properties of black silicon and the efficiency of solar cells made from this material. Now they are working on using different shapes of laser pulses and analysing how this changes the energy level of the sulphur.

In the future, they hope that a system of algorithms will automatically identify how the laser pulse should be modified in order to achieve optimum efficiency. The "˜Customised light pulses' project was one of this year's winners in the "˜365 Places in the Land of Ideas' competition; the awards ceremony is due to be held in Goslar on October 11th, 2012.

The researchers have already successfully built prototypes of black silicon solar cells and their next step will be to try and merge these cells with commercial technology. "We hope to be able to increase the efficiency of commercial solar cells - which currently stands at approximately 17 percent - by 1 percent by combining them with black silicon," Kontermann says.

Their starting point is a standard commercial solar cell. The experts simply remove the back cover and incorporate black silicon in part of the cell, thereby creating a tandem solar cell that contains both normal and black silicon.

The researchers are also planning a spin-off. This company will be used to market the laser system that manufacturers will be able to acquire to expand their existing solar cell production lines. Manufacturers would then be able to produce the black silicon themselves and include it in the cells as standard.