Robots could do your work thanks to MEMS & Lasers

A newly developed scanner technology developed by Fraunhofer IPMS opens up new possibilities for laser scanners and laser projectors.

The Fraunhofer IPMS is part of the Fraunhofer Group Microelectronics, and is engaged in various regional and international networks in microsystems and photonics.

The research institute's new LinScan technology allows switching of the target positions of its laser beam quickly, and a dynamic adjustment of the scanning speed.

3D cameras or miniaturised laser projectors equipped with this technology offer a very high resolution and make innovative solutions possible.

These include robot eyes with sharp vision or compact cell phone projectors with high image quality.

The Fraunhofer Institute for Photonic Microsystems (IPMS) will be presenting this technology to industry professionals at Vision 2012, taking place from November 6th to 8th.

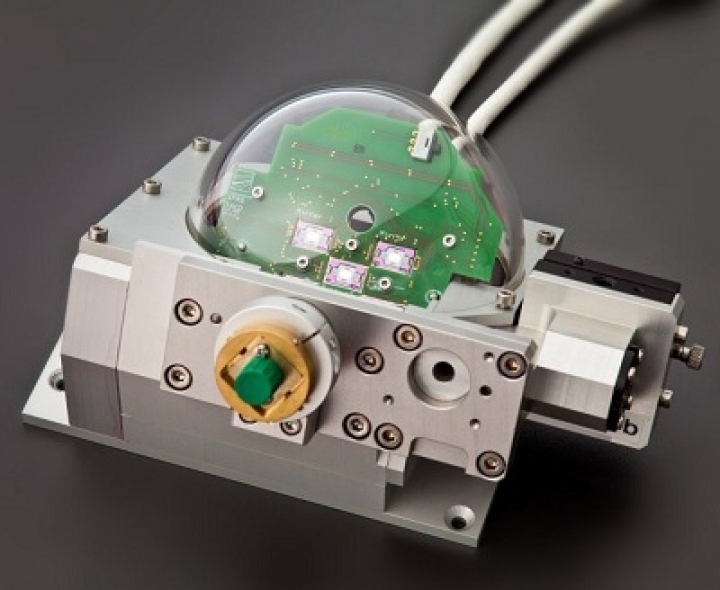

The image above shows an optical scan head of a 3D-TOF-camera with an integrated MEMS scanning mirror array.

IPMS suggests that service robots could replace humans in the future.

In particular, when jobs endanger health and safety, or are too awkward or complicated, or just make life easier for us humans.

However, to rely on the robots to perform such complex tasks independently and reliably, they need to not only see, but also be capable of interpreting their environment. They should also be able to control their vision according to ambient conditions.

This depends on the assumption that their environmental visualisation functions work similarly to the way the human eye does.

In other words, the sharpest area of vision, on the retina of the human eye, or so-called fovea is concentrated upon objects within our surroundings that we deem as interesting or important.

"That is exactly what a camera with LinScan technology is capable of," says Thilo Sandner, Project Manager at Fraunhofer IPMS. He explains, "The camera potentially imitates the human visualisation system by first scanning the surroundings and then resolving interesting objects with greater precision".

Fraunhofer IPMS says the LinScan technology poses a massive developmental leap for applications in compact laser projectors as well.

It is unlike the double-resonant scanning principle used for many pico-projectors. In this technology, the mirror oscillates in a sinusoidal manner with a frequency predefined by the geometry of the component.

LinScan, on the other hand, makes it possible for the laser beam to jump from line to line with a flexible scanning speed.

Image resolutions of SVGA (800 x 600) and more become possible with miniaturised architectures.

The LinScan manufacturing technology developed for resonant microscanners is to tilt the drive combs of the hitherto existing resonant scanner towards each other. This makes the linear drive of the mirror plate on one axis possible.

What's more, a resonant drive with a defined frequency on the fast horizontal axis can be combined with a variable quasi-static oscillation on the vertical axis.

The components are manufactured in the Fraunhofer IPMS cleanroom in a bulk micromachining manufacturing process.

All of the micro-mechanical components are manufactured as two-dimensional structures in a layer of monocrystalline silicon.

The vertical comb electrodes are realised in an adhesive wafer bonding process with a second planar-structured silicon wafer.

Mechanical solid state structures on the second wafer tilt or stagger the in-plane comb drive,The entire device is fixed by subsequent wafer-bonding fusing.

Given the small tolerances of micromachining processes, the structures on the two wafers are optimally aligned to each other. This component concept is extremely flexible and makes it possible to realise a broad spectrum of component characteristics.

One initial prototype of an optical scanning head with five integrated, synchronically operated LinScan scanning mirrors, as well as a linear projector, will illustrate the current technical possibilities of the LinScan component concept.

The double resonant scanning principle will be demonstrated using the examples of both an endomicroscope as well as a confocal 3D fluorescent microscope.

Together, the partners are working on implementing the foveal principle. In other words, the rough scanning of objects appearing within the range of sight, in a 3D camera system to detect the objects looked for, and record objects with a much higher resolution.

The researchers plan to combine the LinScan scanning technology with a three-dimensional object survey. This will be based on time of flight as well as software for ultra-fast object capture to increase comprehension of the surroundings.

Fraunhofer IPMS will be presenting its double resonant scanning technology in addition to LinScan at stand A22 at Vision 2012.