"˜Cloned' Carbon Nanotubes Could Outclass Silicon In Electronics

The heart of the computer industry is known as "Silicon Valley" for a reason. Integrated circuit computer chips have been made from silicon since computing's infancy in the 1960s.

Now, thanks to a team of USC researchers, carbon nanotubes may emerge as a contender to silicon's throne.

Scientists and industry experts have long speculated that carbon nanotube transistors would one day replace their silicon predecessors. In 1998, Delft University built the world's first carbon nanotube transistors.

And according to the USC researchers, carbon nanotubes have the potential to be far smaller faster, and consume less power than silicon transistors.

A key reason carbon nanotubes are not in computers right now is that they are difficult to manufacture in a consistent way. Scientists have had a difficult time controlling the manufacture of nanotubes to the correct diameter, type and ultimately chirality - factors that control nanotubes' electrical and mechanical properties.

You could think of chirality like this: If you took a sheet of notebook paper and rolled it straight up into a tube, it would have a certain chirality. If you rolled that same sheet up at an angle, it would have a different chirality. In this example, the notebook paper represents a sheet of latticed carbon atoms that are rolled up to create a nanotube.

A team led by Professor Chongwu Zhou of the USC Viterbi School of Engineering and Ming Zheng of the National Institute of Standards and Technology (NIST) in Maryland solved the problem by designing a system that consistently produces carbon nanotubes of a predictable diameter and chirality.

"Controlling the chirality of carbon nanotubes has been a dream for many researchers. Now the dream has come true," Zhou says.

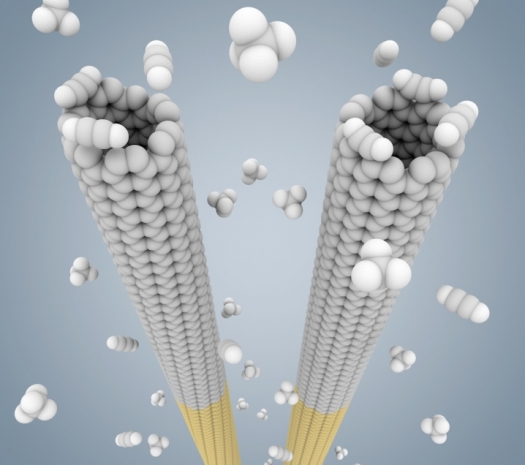

Carbon nanotubes are typically grown using a chemical vapour deposition (CVD) system in which a chemical-laced gas is pumped into a chamber containing substrates with metal catalyst nanoparticles, upon which the nanotubes grow. It is generally believed that the diameters of the nanotubes are determined by the size of the catalytic metal nanoparticles. However, attempts to control the catalysts in hopes of achieving chirality-controlled nanotube growth have not been successful.

To overcome this, the USC team's approach is to use a technique similar to vapour phase epitaxy (VPE).

They jettison the catalyst and plant pieces of carbon nanotubes that have been separated and pre-selected based on chirality, using a nanotube-separation technique developed and perfected by Zheng and his co-workers. Using those pieces as seeds, the team use CVD to extend the seeds to get much longer nanotubes, which were shown to have the same chirality as the seeds.

The process is referred to as "nanotube cloning." The team has already patented its innovation.

The researchers used Raman spectroscopy to show unambiguously that the original chiralities of the nanotube seeds are preserved. They also performed electrical measurements on synthesised individual (7, 6), (6, 5) and (7, 7) nanotubes, confirming their semiconducting nature.

The next steps in the research will be to carefully study the mechanism of the nanotube growth in this system, to scale up the cloning process to obtain large quantities of chirality-controlled nanotubes and to use those nanotubes for electronic applications.

Further details of this research have been published in the paper, "Chirality-controlled synthesis of single-wall carbon nanotubes using vapour-phase epitaxy," by Jia Liu et al in Nature Communications, 3, 1199. DOI:10.1038/ncomms2205