imec Process Correlates FinFET Doping With Device Performance

Imec has developed a new method of probing the 3D-dopant distribution inside FinFET devices and extract important parameters like gate overlap and profile steepness.

The method, which is based on atom probe tomography (APT), has proven successful in linking dopant distributions with device performance. The tool is useful for optimising 3D-doping profiles in next-generation FinFET devices.

In non-planar devices like FinFETs, the formation and optimisation of 3D-dopant profiles is a major challenge, requiring accurate 3D-dopant profiling metrology. Imec has developed an appropriate methodology with sub-nm resolution that is based on the APT technique.

It allows extracting important parameters like dopant gate overlap (i.e., under-diffused dopant depth into the channel) and doping conformality (i.e., similar dopant distribution at top and side walls of the fin). These issues can have a large impact on the FinFET device performance. By using this technique, doping conformality is demonstrated to be a key parameter in controlling gate overlap.

The basic concept of APT is to peel, atom by atom, the surface of a needle shaped sample by means of ionisation and field evaporation. The sequence of atomic emission (peeling) and detection then leads to the re-construction of a 3D volume.

As the field of view in APT is fairly limited, a crucial step is to position the area of interest in the final APT tip. Therefore, it was important to perform a judicious procedure for defining and securing the area of interest during annular milling of the APT tip.

The FinFET devices used for the experiments were fabricated with a standard process flow in which two different doping steps were used, i.e. self regulatory plasma doping (SRPD) and traditional beam-line ion implantation.

The APT results on samples with different doping processes are entirely consistent with the device performances (Ion vs. Ioff). APT is also helpful during the optimisation of the doping process. In case of non-optimised doping (SRPD process A), APT successfully reveals the non-conformality of the dopant distribution by extracting the dopant profiles at the source/drain region as shown in the image below.

![]()

APT image of arsenic (orange) distribution with native oxide (SiO2) at top and side wall of the fin in the source/drain region

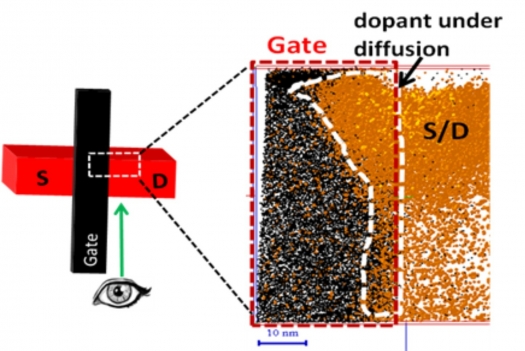

In these samples, the technique demonstrates a much higher doping at the top of the fin, which induces a larger under-diffusion at the top of the fin and thus gate overlap as depicted in the image at the very top of this story.

This image at the very top of this story shows an APT image of arsenic under-diffusion from source/drain region to under the gate (see the schematic) for SRPD process A. Silicon atoms are not shown; orange = As, black = HfO2. The dotted line shows the volume used to construct the 2D distribution. The viewing angle is perpendicular to the dotted line, as the eye shows.

From the electrical measurements, an average gate overlap value of 10nm is deduced, which appears consistent with the 3D measurements.

The conformality in the source/drain region plays a dominant role in the final device performance. Imec used the new methodology to further explore doping process optimisation as illustrated in the graph below.

![]()

Comparison of conformality vs. average concentration in the source/drain region extracted from APT and electrical analysis

The results indicate that the dose at the sidewalls of the fin is the dominant factor influencing the device performance.