SPTS wins multi-system etch order from Tessera

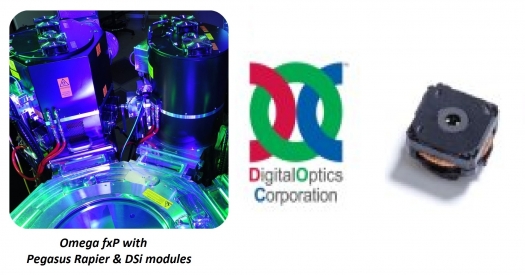

SPTS Technologies has a multi-system order from DigitalOptics Corporation (DOC), a wholly-owned subsidiary of Tessera.

The "Pegasus Rapier" deep silicon etch and "Primaxx HF Vapor" release systems.will be used to manufacture MEMS-based autofocus actuators for smart phone cameras.

Increasingly seen in high-end smart phones, MEMS devices such as the DOC's MEMs actuators are used to automatically position lens elements within the camera to provide a sharper image of the photo's subject.

Micromachined from silicon, successful production of these devices relies on the critical performance of the silicon etch module followed by the stiction-free HF vapour release of the micro-machined components.

Powered by a patented dual source configuration to produce uniform plasma density across the wafer, the Pegasus Rapier DRIE module creates high aspect-ratio features with exceptional profile uniformity and low tilt - key contributors to better device yields translating into cost savings per die. The patented Primaxx HF vapour technology utilises a "dry" etch environment ensuring stiction free release of the lens elements.

"Producing high-performance MEMS autofocus devices requires robust, repeatable and precise manufacturing," says Tony Tang from GM DigitalOptics MEMS. "The Pegasus Rapier met our demanding profile uniformity and tilt goals at cost effective throughputs. These attributes are of critical importance as we commercialise our camera modules. In addition, as an existing user of the Primaxx HF vapour system, we know it delivers the zero stiction, high yield performance we need."

"SPTS continues to expand the use of our systems in major MEMS market applications, with smart phone imaging devices as one key growth area," concludes Kevin T. Crofton, executive vice president and chief operating officer of SPTS."This order confirms SPTS's technology leadership across all areas of MEMS manufacturing."