Dow unveils first CMP polishing pads from IKONIC platform

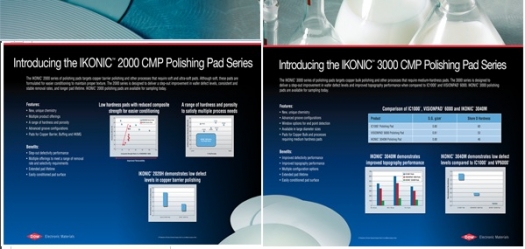

Dow Electronic Materials has launched its first chemical mechanical planarisation (CMP) polishing pads from its IKONI 2000 and IKONIC 3000 series.

All pads in the IKONIC CMP polishing pad platform are designed for use at the 28nm manufacturing node and below, with IKONIC 2000 polishing pads targeting copper barrier, HKMG and buffing applications, and IKONIC 3000 polishing pads developed initially for use in bulk copper polishing.

"We are setting a new benchmark in performance with the launch of the first pads from our new IKONIC pad platform," says Colin Cameron, CMP global marketing director for Dow Electronic Materials. "The new technology used in Dow's IKONIC polishing pads will support our customers' ever-evolving technical requirements demanded by their most advanced processes."

The company says its IKONIC 2020H achieves defectivity levels significantly lower than traditional pads while maintaining removal rate. Also, every pad in the IKONIC 2000 series is formulated to be easily conditioned for optimal texture and longer pad life time. This improves polishing consistency and lowers overall cost of ownership.

IKONIC 3040M is the first polishing pad in the IKONIC 3000 series. This pad delivers a significant reduction in scratch defects compared to other bulk copper pads.

What's more, the IKONIC 3040M has improved topography performance and lower cost of ownership. This pad is available in a range of configurations and options for multiple applications.

"While the IKONIC 2020H and IKONIC 3040M pads are being introduced today, additional pads are in active development in each series that are designed to address a myriad of customer specific requirements. Our IKONIC platform combines a unique set of chemistries with flexible design density, thus allowing us to offer our customers a wide range of customised solutions," concludes Cameron.

Samples are currently available and are going through beta testing with customers.