Accelerating production of next-generation DRAM

Lam Research's Aether dry photoresist technology has been selected by a leading memory manufacturer as production tool of record for the most advanced DRAM processes.

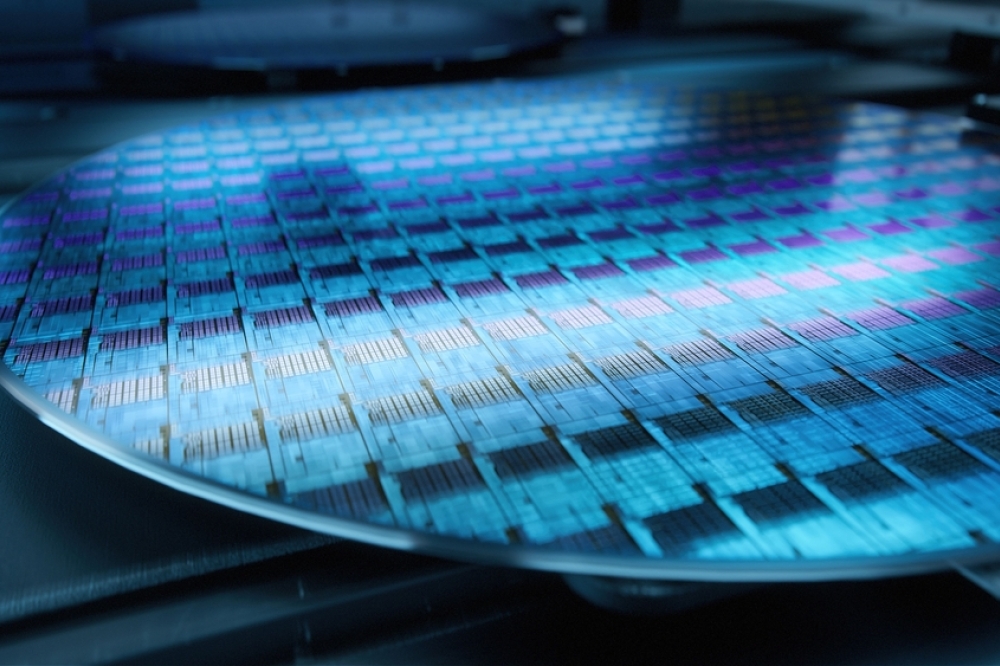

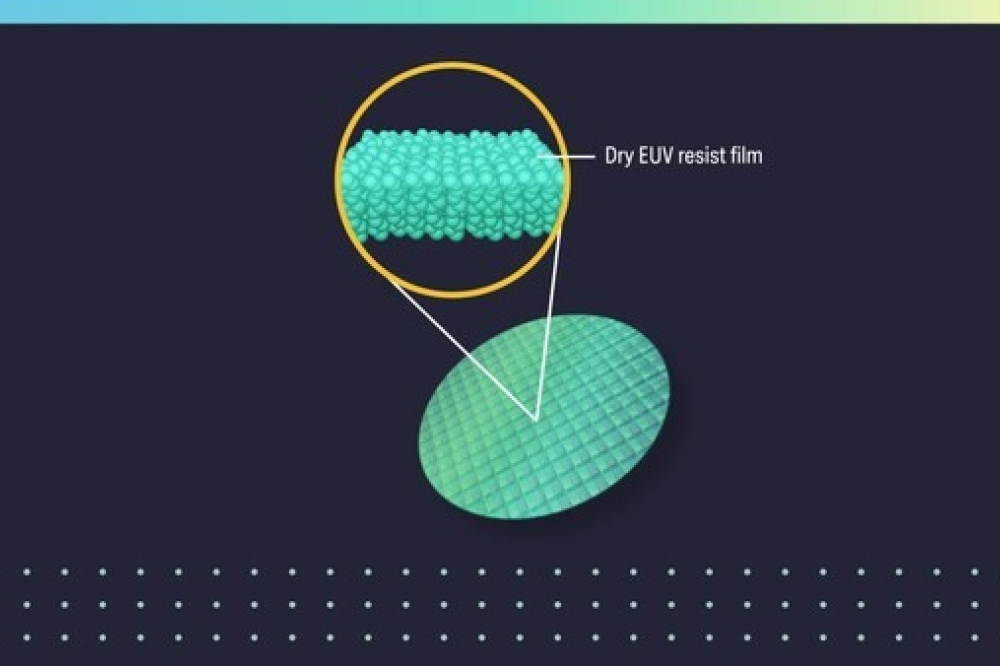

A breakthrough introduced by Lam in 2020, dry resist extends the resolution, productivity, and yield of Extreme Ultraviolet (EUV) lithography, a pivotal technology used in the production of next-generation semiconductor devices.

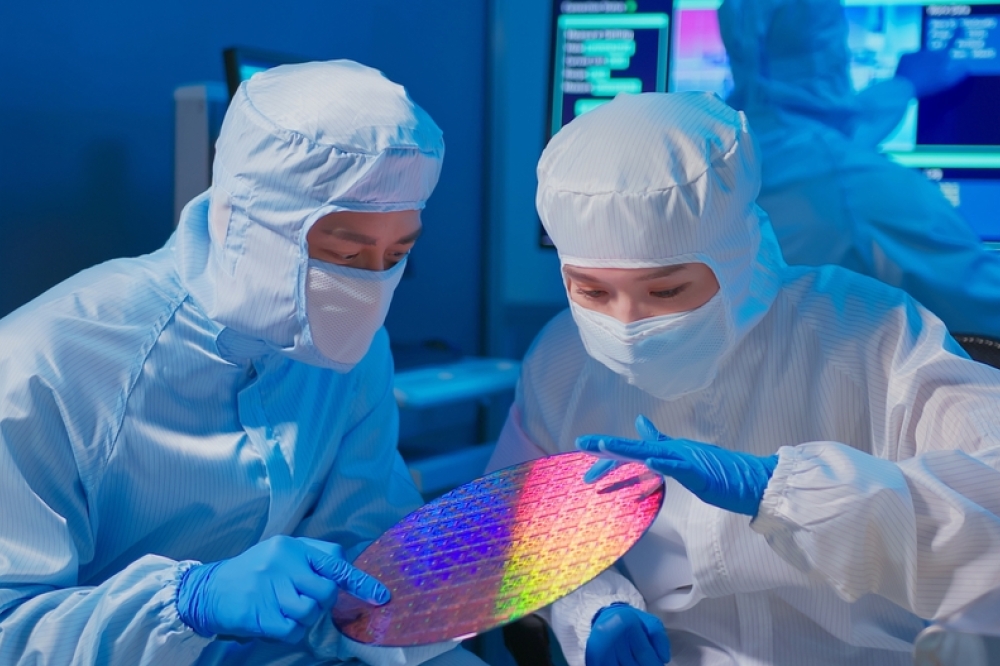

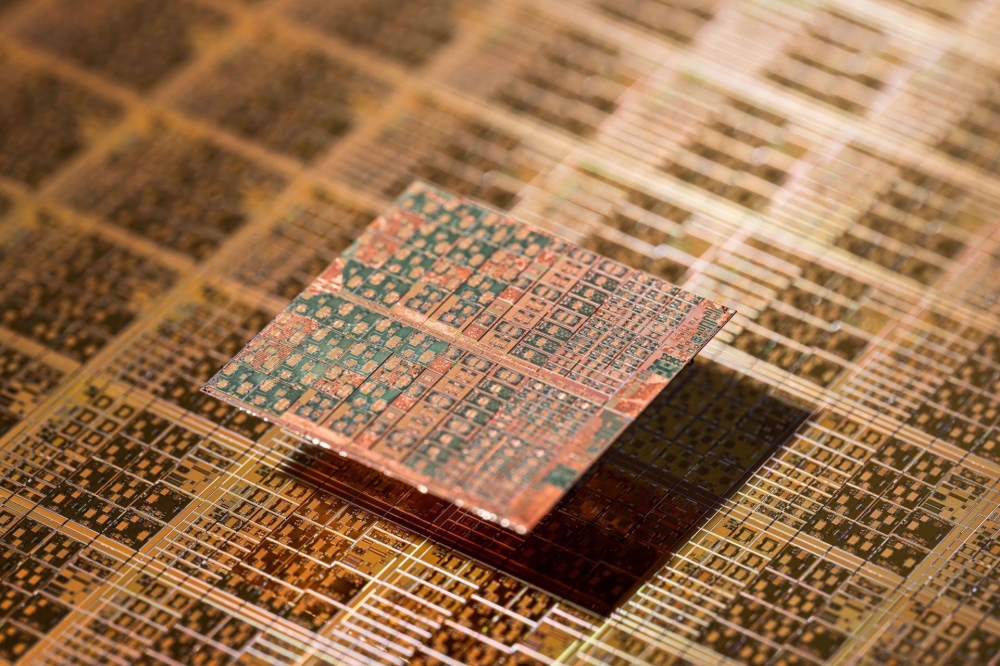

Lam's dry resist approach overcomes the biggest challenges of transferring fine DRAM designs to a wafer.

"Lam's dry resist approach overcomes the biggest challenges of transferring fine DRAM designs to a wafer, delivering low-defect, high fidelity precision, while also offering key advantages in cost and sustainability," said Vahid Vahedi, chief technology and sustainability officer at Lam Research. "We are proud to collaborate with industry leaders to accelerate this DRAM patterning innovation into high-volume manufacturing."

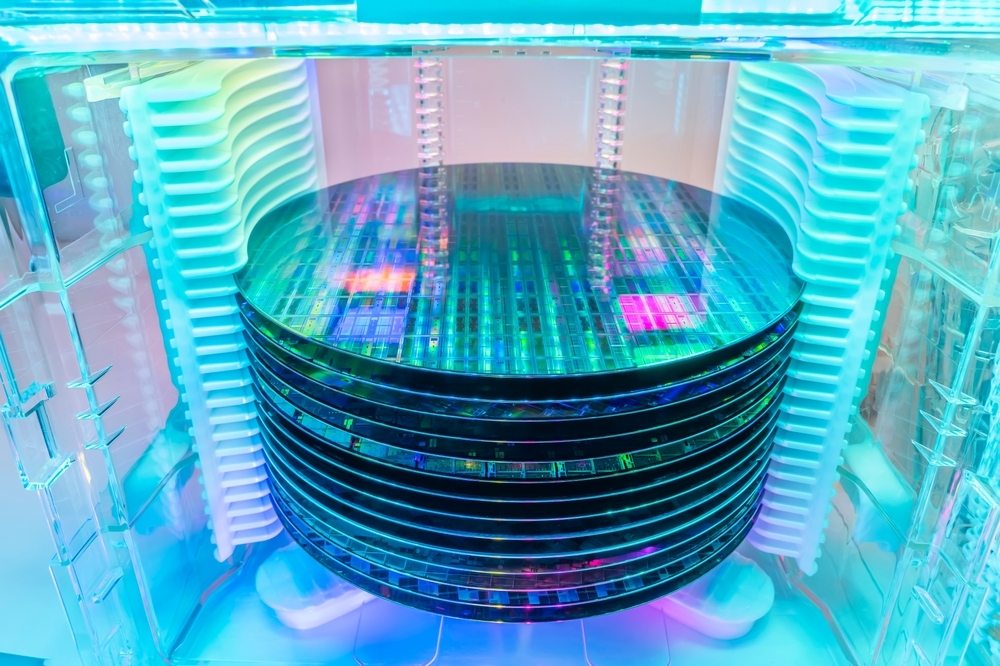

The memory manufacturer will employ the Aether® tools in its most advanced DRAM nodes to form dry resist underlayers and films, and to use dry development processes. These processes overcome the traditional tradeoff between exposure dose and manufacturing defectivity to enable precise, low-defect patterning. This advancement drives down costs and enhances scanner productivity in the manufacturing of next-generation semiconductor devices.

Energy and compute intensive applications require continued scaling of memory capacity in an ever-smaller footprint to enable lower cost per bit of data. A key enabler of this scaling is industry-wide adoption of EUV lithography. Lam's dry photoresist technologies optimize the patterning process from resist application and stack deposition through final etching and cleaning, offering several advantages over conventional chemically amplified resist patterning.

Aether® significantly enhances EUV sensitivity and the resolution of each wafer pass, enabling the most challenging patterns to better adhere to the wafer and improving performance and yield. In addition, it offers key sustainability benefits by consuming less energy and five to ten times less chemicals than traditional wet chemical resist processes.