LAND completes its SPOT+ range

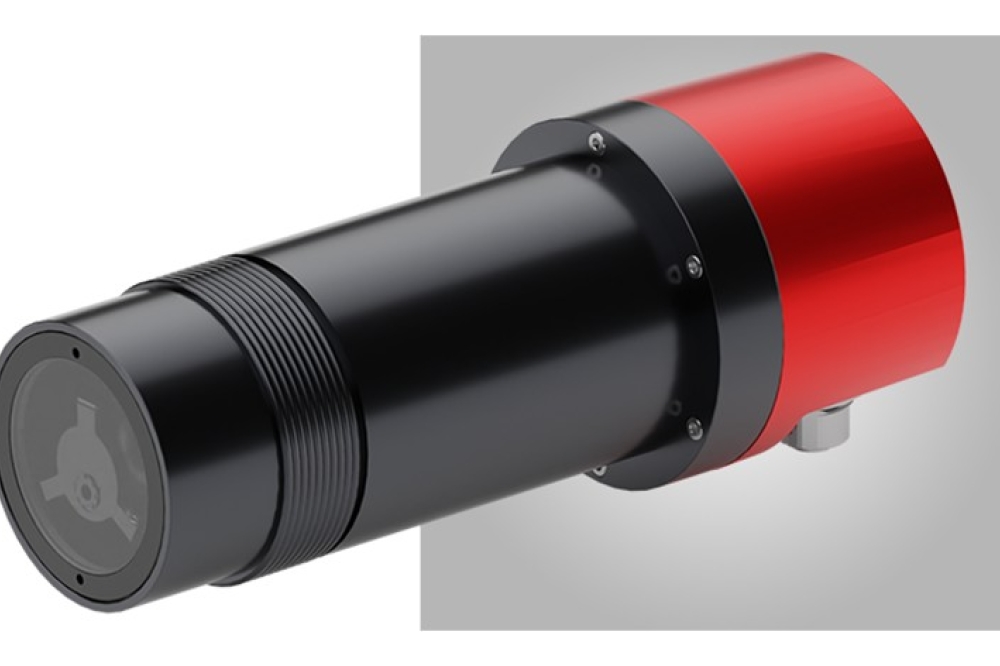

LAND, a business of AMETEK Inc., has expanded its range of SPOT+ smart high-precision pyrometers with the launch of the M390, M3-5, and TMT for wider temperature measurement capabilities.

The SPOT+ M390 joins the M-Series of pyrometers for use in furnaces. This pyrometer is ideal for furnaces where the background is hotter than the object being measured. The SPOT+ M390 overcomes this through its background compensation algorithm. The 3.9 µm wavelength means the measurement is not affected by flames in the measurement path. Its fast 1 ms response time makes it ideal for measurements of moving objects. The wavelength of 3.9 µm, a Field of View (FoV) of 30:1 and temperature measurement range of 150 to 1800 °C (302 to 3272 °F).

With its low temperature measurement capability, the SPOT+ M3-5 is designed for use in processes such as heat treatment, rolling mill coilers and semiconductors where there are typically lower temperatures. It ranges from 0 to 500 °C (32 to 932 °F) and has a FoV of 30:1, with a response time of 10 ms and uses internal temperature for background compensation.

The M3-5 is also perfect for cold rolling mill applications. Cold rolling improves the mechanical characteristics of the metal strip, so a lower temperature measurement is needed to ensure accuracy in the process for a quality product.

For specific tube-wall metal temperature measurements, the SPOT+ TMT has been developed for applications including boilers, steam reformers, steam crackers, cokers and platformers. As with the M390, it is unaffected by flames in the measurement path and includes a background correction algorithm. It provides an industry-leading FoV of 230:1 for measuring small targets at long distances, and a 3.9 µm wavelength.

With measurements of 300 to 1800 °C (572 to 3272 °F) and a response time of 10 ms, it is also compatible with EXSH flameproof housing for hazardous areas and suitable for use in Zone 1, Zone 2, Zone 21 and Zone 22 hazardous areas.

In addition, the SPOT+ TMT can be used in steam methane reformers (SMR) where pyrometers are used as an alternative to thermocouples which can fail in this challenging environment.

Like all SPOT+ pyrometers, they are designed for integration with the Internet of Things, offering Modbus TCP/IP, REST API and EtherNet/IP communications as well as traditional analogue outputs.

Derek Stuart, Global Product Manager said: “I’m pleased to announce the latest models in the SPOT+ range. These allow us to measure temperatures from freezing up to 3500 °C (6332 °F) across a wide range of applications in metals, hydrocarbon processing and other industries. The three new models have been designed for maximum reliability with sapphire windows and no moving parts other than the focus mechanism”.

The SPOT+ range brings high precision to temperature measurements in challenging applications as a standalone solution without the need for additional processors.