How simulation-driven engineering optimises sealing performance for semiconductors

The semiconductor industry operates under extreme

precision requirements where even microscopic failures can result in

significant yield losses and costly downtime. Traditional testing

methods, while reliable, often require months or

years to validate

seal performance under real-world conditions. Offered by component

partners like Trelleborg Sealing Solutions, simulation-driven

engineering is an approach that can predict seal behavior years into the

future within hours of computational analysis.

By Alan Astbury, Simulation Methods Developer, Trelleborg Sealing Solutions

This advanced methodology combines material science expertise with sophisticated computational tools to optimize sealing solutions before they reach production environments. By leveraging simulation technology, engineers can now predict compression set behavior, analyze dynamic responses and optimize seal designs to maximize performance in semiconductor applications.

Understanding Simulation Capabilities in Sealing Applications

Modern simulation technology extends far beyond basic stress analysis. Advanced simulation platforms can model complex material behaviors including hyperelastic properties, viscoelastic responses and long-term aging effects that directly impact seal performance.

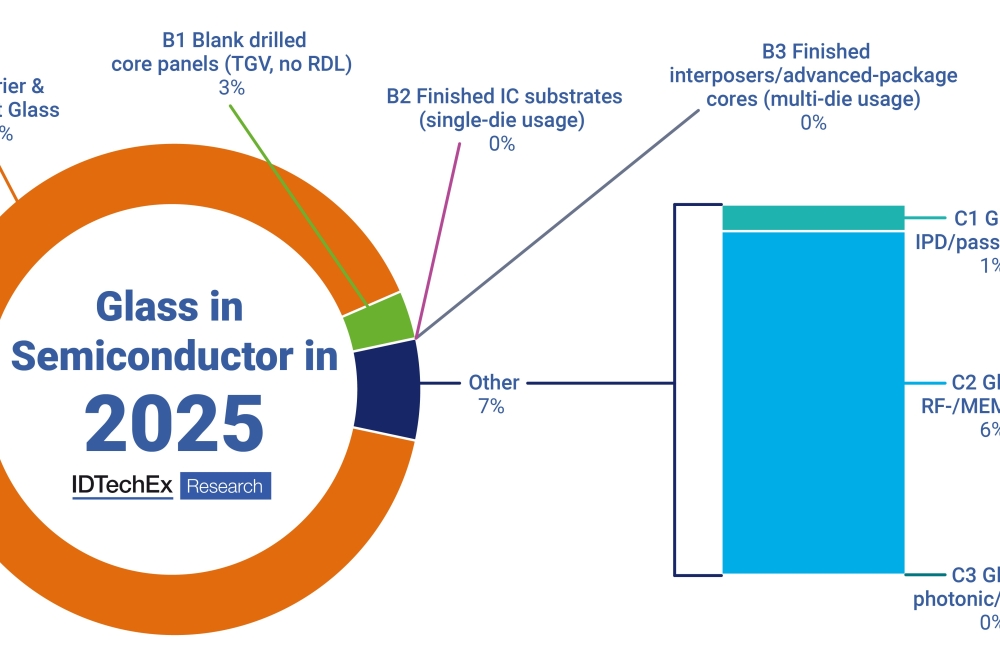

Compression set control volume detecting leakage after a period of time, which is talked about in the article.

Material Behavior Modeling

Elastomer seals exhibit nonlinear behavior under various conditions. Simulation software accounts for these complexities by incorporating hyperelastic material models that accurately represent how seals respond to deformation, temperature changes and dynamic loading conditions. This includes modeling the Mullins effect, where loading and unloading cycles on a material follow different stress-strain paths.

The simulation process begins with comprehensive material characterization using standard tensile testing equipment and dynamic mechanical analyzers (DMA). The DMA generates frequency sweeps at various temperatures, providing essential data for calibrating simulation models to match real-world material behavior.

Multi-Stage Analysis Approach

Expert seal suppliers like Trelleborg approach seal simulation with a multi-stage analysis. The process typically begins with thermomechanical analysis, where engineers couple mechanical responses with temperature effects and thermal expansion. This is followed by aging simulation using specialized subroutines that predict long-term material property changes. Finally, the analysis concludes by bringing the model back to normal conditions to assess final seal performance.

One of the most valuable applications of simulation-driven engineering is predicting compression set behavior over extended periods. Compression set occurs when elastomer seals lose their ability to return to original dimensions after prolonged compression, directly impacting sealing effectiveness.

At the molecular level, elastomers consist of long polymer chains connected by cross-links. Under sustained compression and elevated temperatures, these cross-links break and reform at shorter distances, preventing the seal from returning to its original shape. Simulation models replicate this behavior by tracking bond breaking and reformation processes over time.

Temperature and time are the primary drivers of compression set. Higher temperatures accelerate the process, which simulation engineers leverage through time-temperature shifting principles. This approach allows validation of years-long predictions using accelerated testing at elevated temperatures.

Compression set after 37 years compared to a real O-Ring.

Practical Applications in Semiconductor Equipment

Consider a dual seal arrangement in semiconductor processing equipment designed to operate for seven years. Through aging simulation, engineers can predict when contact pressure will drop below critical thresholds, enabling proactive maintenance scheduling. The simulation might reveal that a pressure relief channel will lose contact after seven years while maintaining primary sealing function, providing an early warning system for maintenance needs. This predictive capability eliminates the need for extensive long-term testing while providing confidence in seal performance throughout the equipment’s operational life.

Dynamic Response Analysis and Optimization

Semiconductor manufacturing equipment often involves dynamic conditions including vibrations, pressure fluctuations and mechanical movements. Nonlinear viscoelastic simulation addresses these challenges by modeling both elastic and damping properties of seal materials. In a nonlinear viscoelastic simulation, the material’s response to stress or strain is not directly proportional to the applied load. This means that the relationship between stress and strain is more complex and can change depending on the magnitude and duration of the applied forces.

Vibration Isolation and Damping Optimization

Dynamic simulation enables engineers to optimize seal designs for specific frequency responses. For applications requiring vibration isolation, such as protecting sensitive measurement equipment from environmental disturbances, simulation can identify optimal material properties and geometric configurations. The analysis considers natural frequencies and damping characteristics to achieve desired isolation performance. By testing multiple material formulations virtually, engineers can select the optimal combination before manufacturing prototype parts.

Advanced Simulation Capabilities

Simulation extends beyond seal performance to manufacturing process optimization.

Wear Prediction Modeling

Seals in semiconductor equipment experience continuous wear throughout their service life. Advanced simulation techniques can predict wear patterns over months of operation, showing how sharp seal edges gradually wear to flat surfaces. This capability enables engineers to optimize seal geometries for extended service life. Wear simulation correlates well with real-world measurements, providing confidence in predicted maintenance intervals and helping prevent unexpected failures.

Design Optimization Techniques

Modern simulation platforms offer both parametric and non-parametric optimization capabilities. Parametric optimization adjusts specific dimensional parameters to achieve performance targets, such as reducing stress concentrations by 11 percent through heel geometry modifications. Non-parametric optimization, while less applicable to sealing applications due to its tendency to create holes in components, proves to be a valuable technique for structural elements and assembly tooling design.

.

Manufacturing Integration and Quality Assurance

Simulation also ensures part quality from production. Injection molding simulation optimizes heating channel designs, gate locations and process parameters to achieve uniform material flow and minimize defects. It enables proactive quality management by identifying potential failure modes before they occur in service. Simulations account for material shrinkage, enabling precise tolerance control in final parts. This capability is particularly important for semiconductor seals where dimensional accuracy directly impacts performance.

Preventative Maintenance Scheduling

Advanced aging simulation provides specific timelines for seal replacement, enabling equipment operators to schedule maintenance during planned downtime rather than responding to unexpected failures. This approach significantly reduces overall maintenance costs and improves equipment uptime.

Material Selection Optimization

Simulation facilitates rapid comparison of different seal materials for specific applications. Engineers can evaluate how various elastomer formulations respond to temperature cycling, chemical exposure and mechanical stress without extensive physical testing.

The Future of Simulation in Sealing Technology

Emerging trends in simulation technology point toward molecular-level modeling capabilities that will enable virtual chemical compatibility testing. While these advanced techniques remain several years from practical implementation, they represent the next frontier in predictive seal engineering.

Multi-scale modeling approaches will eventually bridge molecular behavior with macroscopic seal performance, providing unprecedented insight into material behavior under various service conditions.

Maximizing Value Through Simulation Partnership

Simulation-driven engineering delivers the greatest value when integrated early in the design process. It also requires close collaboration between a seal supplier like Trelleborg, equipment manufacturers and end users, to ensure models accurately represent real-world operating conditions. Engineers can explore multiple design alternatives and optimize performance before committing to tooling and production.

This partnership approach maximizes the predictive value of simulation analysis and ensures optimal seal performance throughout the equipment lifecycle.

Modern semiconductor manufacturing demands precision and reliability that traditional design approaches cannot guarantee. Simulation-driven engineering provides the predictive capabilities necessary to meet these demanding requirements while reducing development time and costs. As simulation technology continues advancing, its role in sealing optimization will only grow more critical to industry success.