AAF International teams with Airtho and the University of New Hampshire

AAF’s dynamic AstroFan EC FFU and MEGACel II duo used to create ultimate particulate filtration solution for new, state-of-the-art clean room at the University’s renowned John Olson Advanced Manufacturing Center.

AAF International recently joined The Honorable Kelly Ayotte, Governor of New Hampshire, as well as local dignitaries and leaders from the University of New Hampshire (UNH) to unveil a new, state-of-the art ISO 7 Clean Room at the University’s John Olson Advanced Manufacturing Center.

Led by the University and Airtho, a leader in developing controlled environment solutions, the clean room is a technology hub for high-tech industrial partners looking for spaces to advance innovation, while giving University students the opportunity for real-world, hands-on learning. Governor Ayotte was joined today by Brandon Bogard, President and Founder of Airtho; John Roth, Director - John Olson Advanced Manufacturing Center and Professor - Mechanical Engineering; Cyndee Gruden, the Dean of UNH's College of Engineering and Physical Sciences (CEPS); and Kay Devlin, Senior Director of Marketing for AAF International, as well as other dignitaries.

“We are thrilled to partner with our friends at Airtho and the distinguished staff and faculty at the renowned Olson Center on such a dynamic project,” says Mike Sehgal, Global Director High Purity Segment Microelectronics & EV Battery, AAF International. “This project advances industry and creates valuable learning experiences for today’s students and tomorrow’s leaders.”

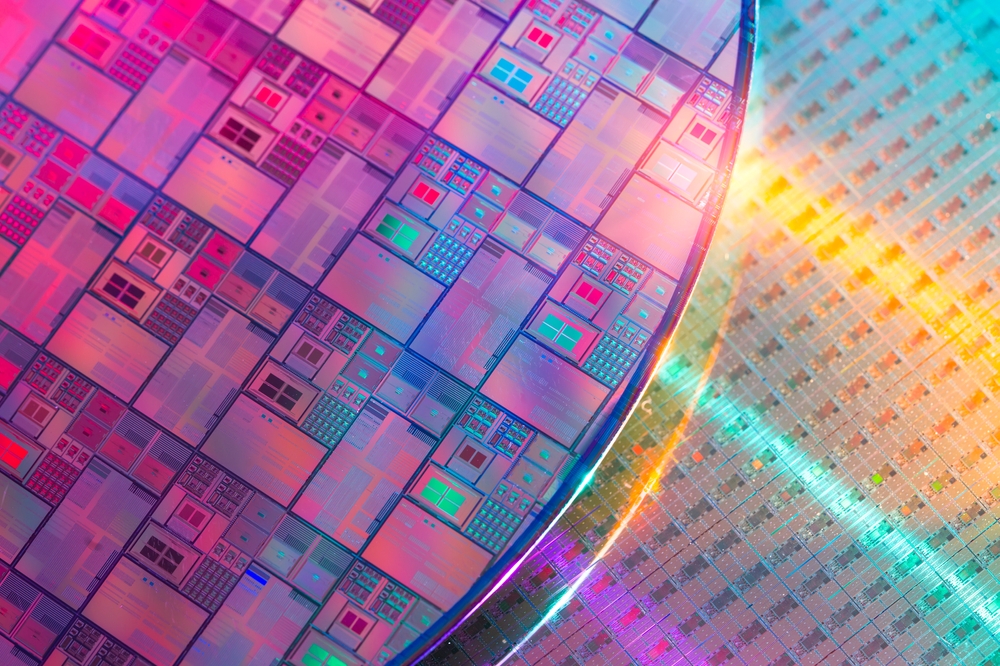

Key to the clean room’s construction is the use of advanced filtration products from AAF International which are vital to many industries, particularly electronics, pharmaceuticals, semiconductors, medical equipment, space, and marine. “Advanced HEPA filtration is critical to clean room applications to remove pollutants such as dust, airborne microbes, and aerosol particles to maintain the highest levels of cleanliness and hygiene,” adds Sehgal.”

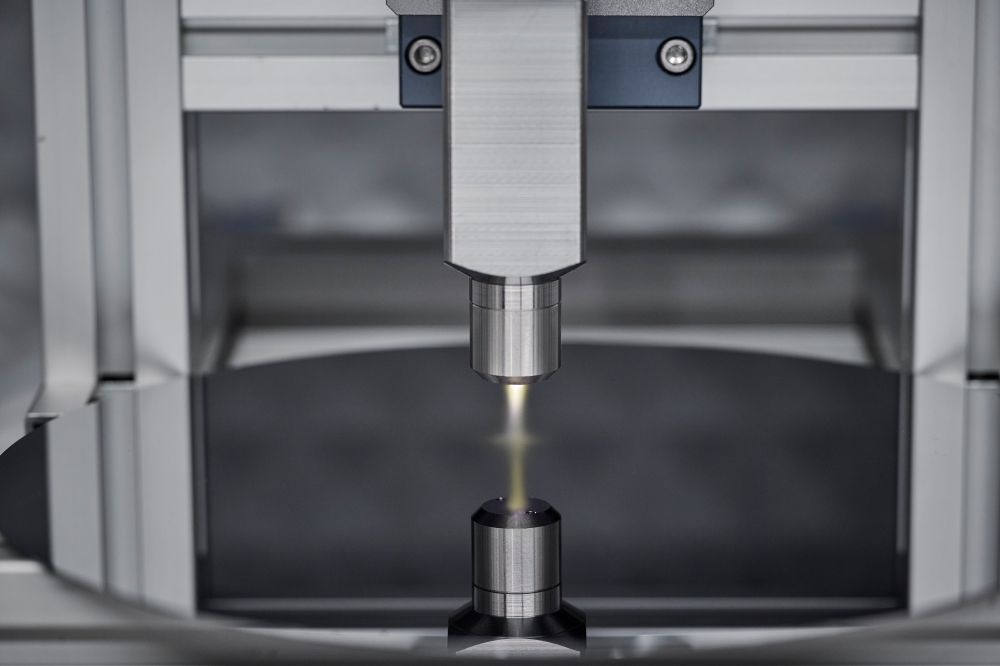

The Olson Center Clean Room features the combination of AAF’s AstroFanTM EC FFU and MEGACel® II ME, designed for maximum airflow efficiency, ease of use, and powerful filtration. The tandem is well-suited for cleanrooms supporting microelectronic fabrication, semiconductor manufacturing, medical device manufacturing and assembly, pharmaceutical processing, sterile compounding pharmacies, hazardous drug and/or material handling, as well as all other regimented and regulated applications.

AstroFan EC Fan Filter Units are ideal for use in all applications requiring controlled clean air, with whisper-quiet operation, top-side servicing or room-side replacement, high efficiency airflow rates, and multiple sizes.

For the Olson Center clean room application, AAF’s MEGACel® II ME membrane-media HEPA filter is designed to help increase cleanroom uptime and reduce risks. In addition to its durability, high particulate filtration efficiency and lowest pressure drop, the MEGAcel II ME is the industry’s first and only membrane media compatible with polyalphaolefin (PAO) for HVAC validation.

“The Olson Center Clean Room will serve as a catalyst for advancing the next generation of manufacturing, empowering students and businesses to shape the future of innovation,” continues Sehgal. “We are extremely proud to support this collaboration as it helps highlight the importance advanced filtration plays in bringing innovation to the marketplace.”