Automated Thickness Measurement System Speeds Production

The labor-intensive, manual process of recording precise measurements across various wafer coordinates is now programmable for automated data collection and report generation.

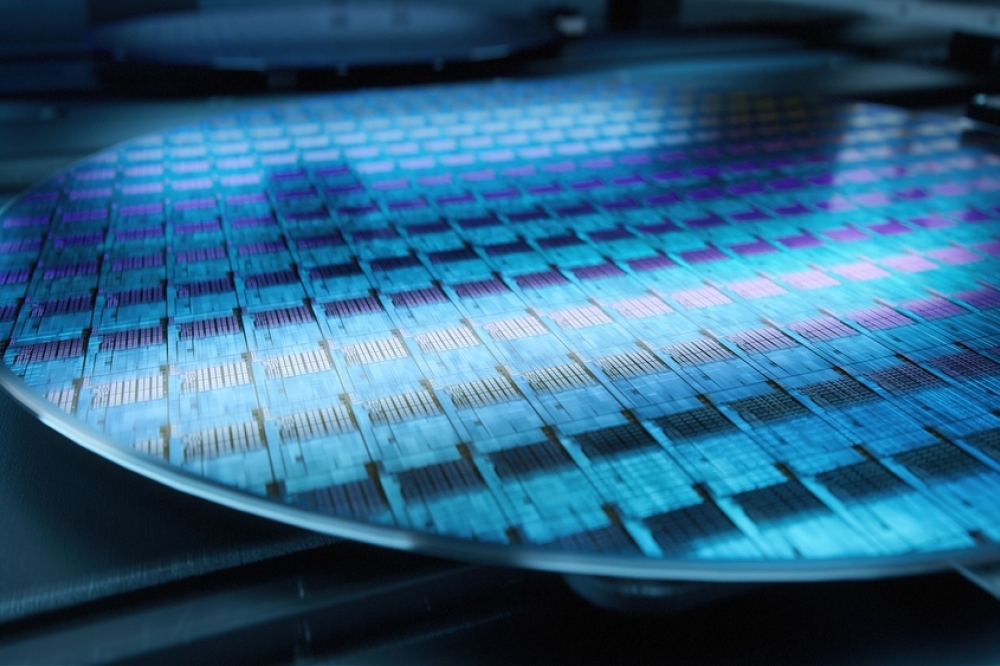

ACU-THIK is an automated thickness measurement tool incorporating dual contact probes for high accuracy inspection of semiconductor wafers. Six Heidenhain measuring devices are integrated into the ACU-THIK system which can be configured to accommodate wafer diameters of 100 mm "“ 400 mm and larger. Acu-Gage customers can have a system customized for their precise needs to make differential gage measurement faster and easier.

Diagnosing as well as controlling thickness, bow and warp in semiconductor wafer production is now automated when using ACU-THIK. Users can preprogram multiple pattern operations to fulfill planned production cycles. Additionally, the system supports robotics integration to further free up operators for other important tasks.

ACU-THIK's automated measurements can improve quality-assured production yields by:

"¢ Calculating wafer thickness across X/Y points to resolution and repeatability of .00025mm/.00001 inch (10 millionths of an inch)

"¢ Determining the amount of bow deviation in an unclamped wafer established by three or more points at equidistant locations

"¢ Examining the entire wafer for warp by incorporating more comprehensive data points to provide a more useful measurement of the full wafer shape

"¢ Accelerating throughput with 15 data points of X/Y thickness measurements in under two minutes as well as increasing accuracy of wafer thickness and flatness definitions

"¢ Validating pre- and post-measurement integrity of data collection for each wafer inspection - ACU-THIK calculates the thickness of a certified gage block prior to as well as after the wafer inspection routine is complete.

The X/Y location for each thickness data point automatically outputs to Excel for further analysis. Programming software runs on Windows 7. Both hardware and software come delivered as a turnkey system including installation and training.