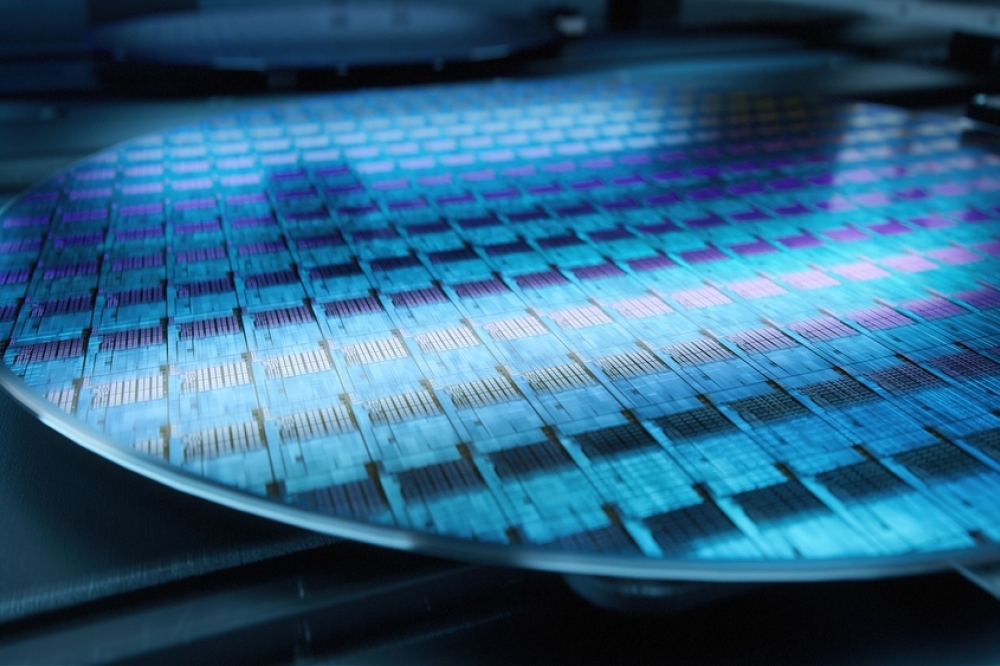

New generation of transient electronic devices

![]()

Credit: J.Rogers/UIUC

Electronic devices that dissolve completely in water, leaving behind only harmless end products, are part of a rapidly emerging class of technology pioneered by researchers at the University of Illinois at Urbana-Champaign.

Early results demonstrate the entire complement of building blocks for integrated circuits, along with various sensors and actuators with relevance to clinical medicine, including most recently intracranial monitors for patients with traumatic brain injury. The advances suggest a new era of devices that range from green consumer electronics to 'electroceutical' therapies, to biomedical sensor systems that do their work and then disappear.

John A. Rogers' research group at the Department of Materials Science and Engineering Frederick Seitz Materials Research Laboratory is leading the development of such concepts, along with all of the required materials, device designs and fabrication techniques for applications that lie beyond the scope of semiconductor technologies that are available today.

"Our most recent combined developments in devices that address real challenges in clinical medicine and in advanced, high volume manufacturing strategies suggest a promising future for this new class of technology," said Rogers. He will present these and other results at the AVS 61st International Symposium & Exhibition, being held November 9-14, 2014 in Baltimore, Md.

Practical applications might include: bioresorbable devices that reduce infection at a surgical site. Other examples are temporary implantable systems, such as electrical brain monitors to aid rehabilitation from traumatic injuries or electrical simulators to accelerate bone growth. Additional classes of devices can even be used for programmed drug delivery, Rogers said.

Such envisioned uses are all best satisfied by devices that provide robust, reliable, high performance operation, but only for a finite period of time dictated, for example, by the healing process -- they are not only biologically compatible, but they are biologically punctual, performing when and as the body needs them.

After their function has been fulfilled, they disappear through resorption into the body, thereby eliminating unnecessary device load, without the need for additional surgical operations. In terms of consumer electronics, the technology holds promise for reducing the environmental footprint of the next generation of "green" devices.