Quick-change materials break silicon speed limit for computers

Faster, smaller, greener computers, capable of processing information up to 1,000 times faster than currently available models, could be made possible by replacing silicon with materials that can switch back and forth between different electrical states.

The present size and speed limitations of computer processors and memory could be overcome by replacing silicon with 'phase-change materials' (PCMs), which are capable of reversibly switching between two structural phases with different electrical states -- one crystalline and conducting and the other glassy and insulating -- in billionths of a second.

Modelling and tests of PCM-based devices have shown that logic-processing operations can be performed in non-volatile memory cells using particular combinations of ultra-short voltage pulses, which is not possible with silicon-based devices.

In these new devices, logic operations and memory are co-located, rather than separated, as they are in silicon-based computers. These materials could eventually enable processing speeds between 500 and 1,000 times faster than the current average laptop computer, while using less energy. The results are published in the journal Proceedings of the National Academy of Sciences.

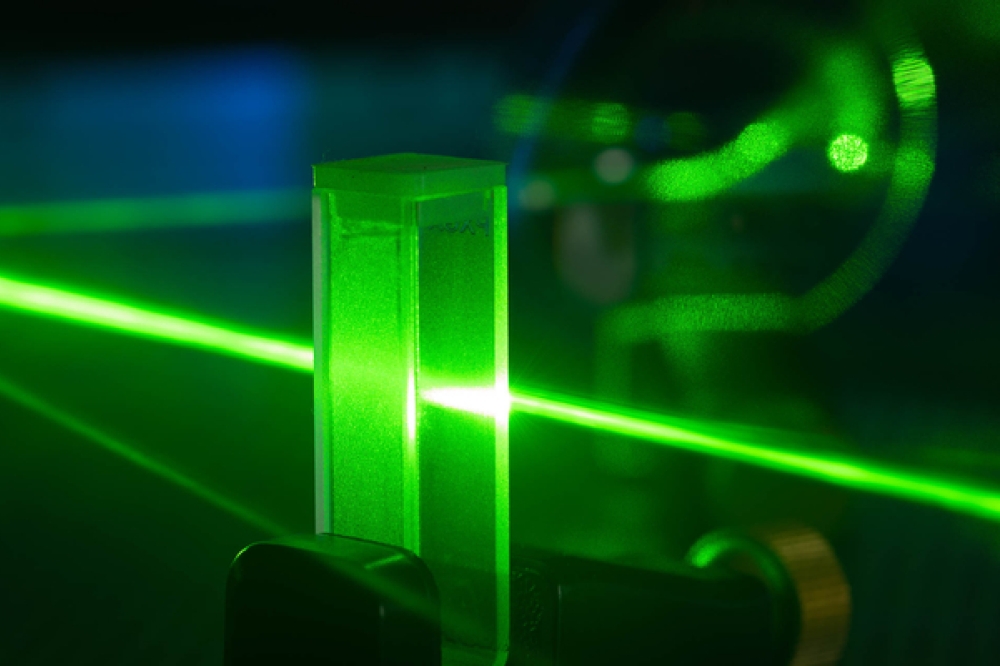

The processors, designed by researchers from the University of Cambridge, the Singapore A*STAR Data-Storage Institute and the Singapore University of Technology and Design, use a type of PCM based on a chalcogenide glass, which can be melted and recrystallized in as little as half a nanosecond (billionth of a second) using appropriate voltage pulses.

The calculations performed by most computers, mobile phones and tablets are carried out by silicon-based logic devices. The solid-state memory used to store the results of such calculations is also silicon-based. "However, as demand for faster computers continues to increase, we are rapidly reaching the limits of silicon's capabilities," said Professor Stephen Elliott of Cambridge's Department of Chemistry, who led the research.

The primary method of increasing the power of computers has previously been to increase the number of logic devices which they contain by progressively reducing the size of the devices, but physical limitations for current device architectures mean that this is quickly becoming nearly impossible to continue.

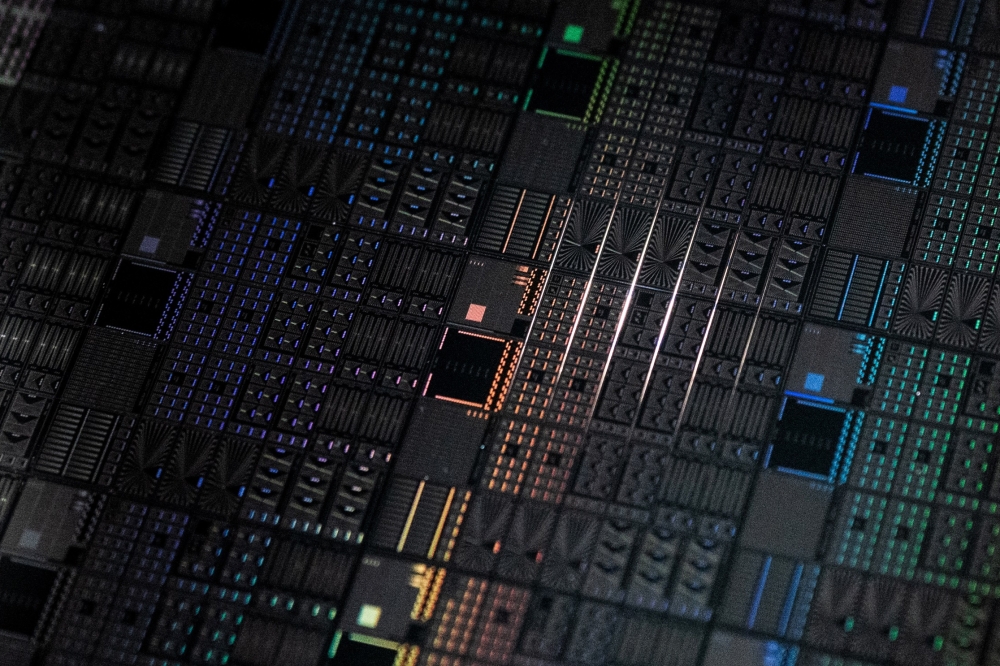

Currently, the smallest logic and memory devices based on silicon are about 20 nanometres in size -- approximately 4000 times thinner than a human hair -- and are constructed in layers. As the devices are made ever smaller in order to increase their numbers on a chip, eventually the gaps between the layers will get so small that electrons which are stored in certain regions of flash non-volatile memory devices will be able to tunnel out of the device, resulting in data loss. PCM devices can overcome this size-scaling limit since they have been shown to function down to about two nanometres.

An alternative for increasing processing speed without increasing the number of logic devices is to increase the number of calculations which each device can perform, which is not possible using silicon, but the researchers have demonstrated that multiple calculations are possible for PCM logic/memory devices.

First developed in the 1960s, PCMs were originally used in optical-memory devices, such as re-writable DVDs. Now, they are starting to be used for electronic-memory applications and are beginning to replace silicon-based flash memory in some makes of smartphones.

The PCM devices recently demonstrated to perform in-memory logic do have shortcomings: currently, they do not perform calculations at the same speeds as silicon, and they exhibit a lack of stability in the starting amorphous phase.

However, the Cambridge and Singapore researchers found that, by performing the logic-operation process in reverse -- starting from the crystalline phase and then melting the PCMs in the cells to perform the logic operations -- the materials are both much more stable and capable of performing operations much faster.

The intrinsic switching, or crystallization, speed of existing PCMs is about ten nanoseconds, making them suitable for replacing flash memory. By increasing speeds even further, to less than one nanosecond (as demonstrated by the Cambridge and Singapore researchers in 2012), they could one day replace computer dynamic random-access memory (DRAM), which needs to be continually refreshed, by a non-volatile PCM replacement.

In a silicon-based system, information is shuffled around, costing both time and energy. "Ideally, we'd like information to be both generated and stored in the same place," said Dr Desmond Loke of the Singapore University of Technology and Design, the paper's lead author. "Silicon is transient: the information is generated, passes through and has to be stored somewhere else. But using PCM logic devices, the information stays in the place where it is generated."

"Eventually, what we really want to do is to replace both DRAM and logic processors in computers by new PCM-based non-volatile devices," said Professor Elliott. "But for that, we need switching speeds approaching one nanosecond. Currently, refreshing of DRAM leaks a huge amount of energy globally, which is costly, both financially and environmentally. Faster PCM switching times would greatly reduce this, resulting in computers which are not just faster, but also much 'greener'."

The research was part-funded by the UK Engineering and Physical Sciences Research Council (EPSRC).

http://www.cam.ac.uk/research/news/quick-change-materials-break-the-silicon-speed-limit-for-computers