PulseForge and ERS electronic collaborate

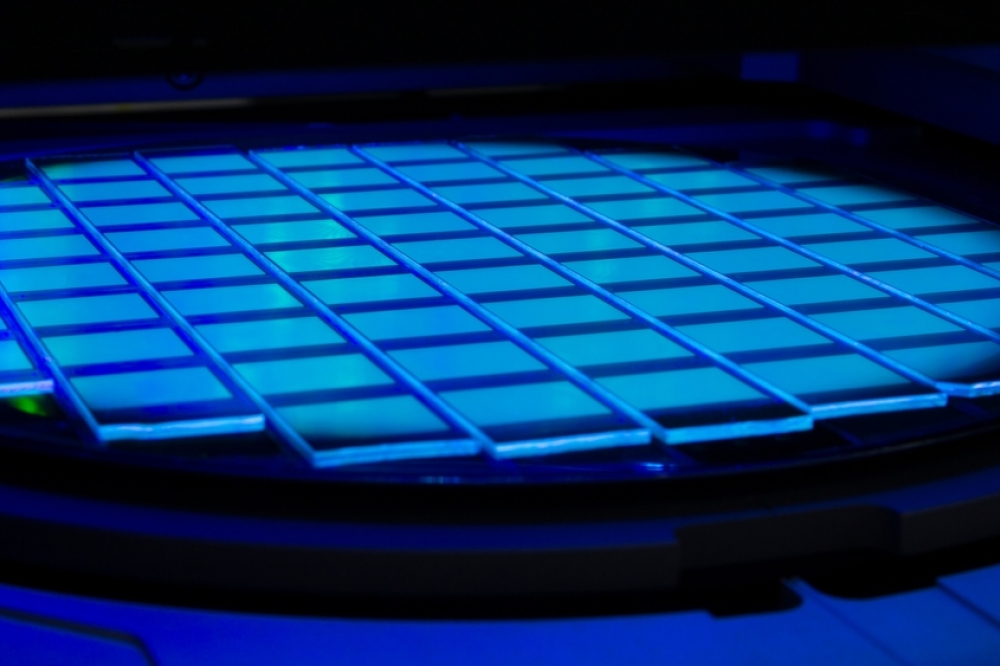

PulseForge, Inc. and ERS electronic GmbH have announced a strategic alliance to bring a fully-automated photonic debonding solution to the semiconductor industry.

This collaboration brings together the industry leader in thermal management solutions for semiconductor manufacturing, ERS electronic, and an industry innovator in applied thermal energy, PulseForge, Inc. ERS electronic will incorporate PulseForge’s patented Photonic Debonding process, thereby expanding their existing portfolio of thermal debond machines, which have already processed more than 2 billion IC.

The ERS fully-automated photonic debonding solution will be ideal for the fan-out wafer-level packaging industry, combining the process and economic benefits of photonic debonding with ERS’s automation capabilities and patented AirCushion transport technology for contactless handling. Together, this will allow for streamlined operations and increased output, while maintaining the highest standards of quality. In addition, this collaboration aims to offer a fully automated debonding solution on both wafer and panel-level to address the various format requirements of the advanced packaging industry. The integration of PulseForge’s patented Photonic Debonding process will significantly reduce the total cost of ownership for debonding customers versus traditional debonding methods providing a clean and cost-effective debonding solution.

“We are excited to bring fully-automated systems to our customers for high-volume manufacturing environments by partnering with ERS electronic.” said Jonathan Gibson, CEO of PulseForge, Inc. “This partnership will provide customers with significantly lower costs for debonding processing.”

“We are thrilled to partner with the PulseForge team and combine our respective strengths to bring large-scale photonic debonding to Advanced Packaging,” says Laurent Giai-Miniet, CEO of ERS electronic. “Our 15 years of customer experience in high-volume thermal debonding will allow us to deliver a reliable, cost-effective, and high-yield system to the semiconductor manufacturing industry.”