U.S. Government accredits GlobalFoundries

Securely manufactured chips to be used in DoD systems on land, air, sea, and in space.

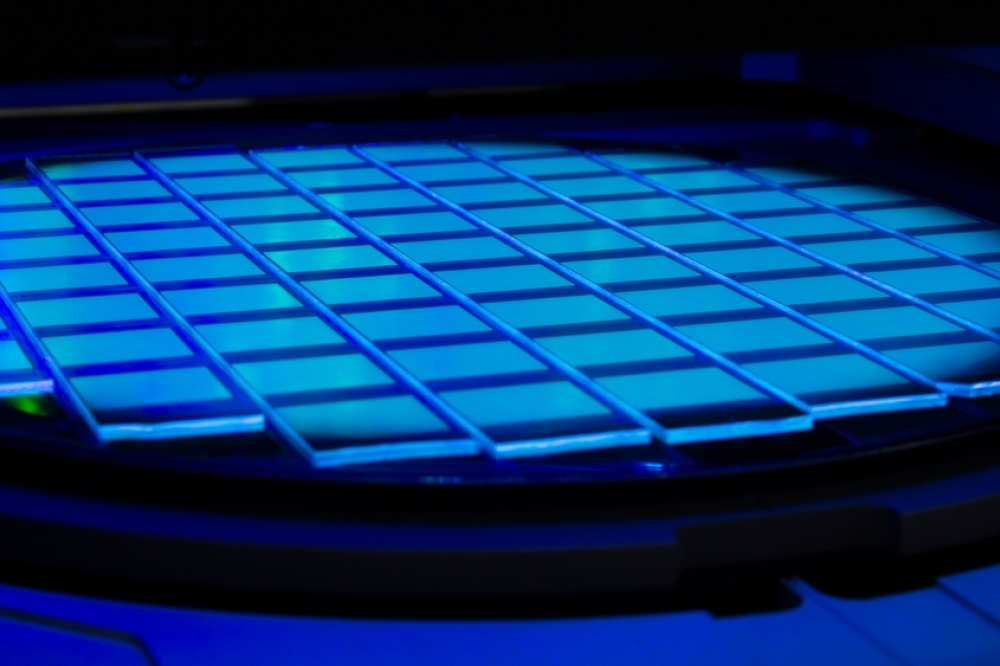

The U.S. Department of Defense (DoD), through the Defense Microelectronics Activity (DMEA), Trusted Access Program Office (TAPO), has accredited GlobalFoundries’ (Nasdaq: GFS) (GF) advanced manufacturing facility in Malta, New York, as a Category 1A Trusted Supplier with the ability to manufacture secure semiconductors for a range of critical aerospace and defense applications.

The latest milestone in the longstanding partnership between the DoD and GF, the accreditation was enabled by GF’s ability to meet DoD requirements for having stringent security processes, equipment, and oversight in place to accept and protect sensitive information and manufacture Trusted chips in a way that ensures they are secure and uncompromised. These securely manufactured chips include those manufactured on GF’s most advanced 12nm FinFET technologies, and will be used in DoD systems on land, air, sea, and in space.

“The secure manufacturing of semiconductors is critical to safeguarding the confidentiality, integrity, and reliability of the technology that powers our modern world, and nowhere is this more important than aerospace, defense, and critical infrastructure systems,” said Dr. Thomas Caulfield, president and CEO of GF. “We are proud to deepen our relationship with the Defense Department, and to receive DMEA accreditation at our New York manufacturing facility. GF’s differentiated chip technologies provide optimized performance for critical DoD systems, and we are uniquely positioned by our ability to provide secure semiconductor manufacturing at scale.”

Dr. Nicholas Martin, DMEA Director, said: “This accreditation at the Malta site will enable the Department to have access to the most advanced ASIC technology node available from a DMEA accredited Trusted Supplier. Accrediting GlobalFoundries to manufacture our country’s sensitive chips strengthens the domestic microelectronics industrial base and our nation’s efforts to fortify its semiconductor supply chain for national and economic security. Trusted Supplier accreditation continues to be a benchmark in semiconductor assurance and will ensure the DoD has reliable access to a range of securely manufactured chips it needs for its defense systems and is the latest collaboration in the longstanding partnership between the DoD and GF to provide silicon-based semiconductors for defense and aerospace applications.”

In 2022, the DoD, through the Manufacturing Capability Expansion and Investment Prioritization (MCEIP) Directorate, entered a $117 million agreement with GF to provide a strategic supply of U.S.-made semiconductors built in Malta, New York, on GF’s differentiated 45nm SOI platform. This accreditation adds to GF’s New York Facility’s compliance with U.S. International Traffic in Arms Regulations (ITAR) and highly restrictive Export Control Classification Numbers under the Export Administration Regulations (EAR). GF employs approximately 2,500 people in Malta, New York, and has invested more than $15 billion in the facility. GF also manufactures Trusted semiconductor chips for the DoD at its facility in Vermont.