Greene Tweed introduces Canted Coil MSE Sealing solution

Reduces power loss and improves precision movement without sacrificing leakage control or durability.

Greene Tweed introduces the new Canted Coil MSE® (metal spring energized) sealing solution, designed to further reduce power loss and improve precision movement without sacrificing leakage control or durability. The seals offer broad chemical compatibility and resistance to extreme temperatures, pressure, and wear.

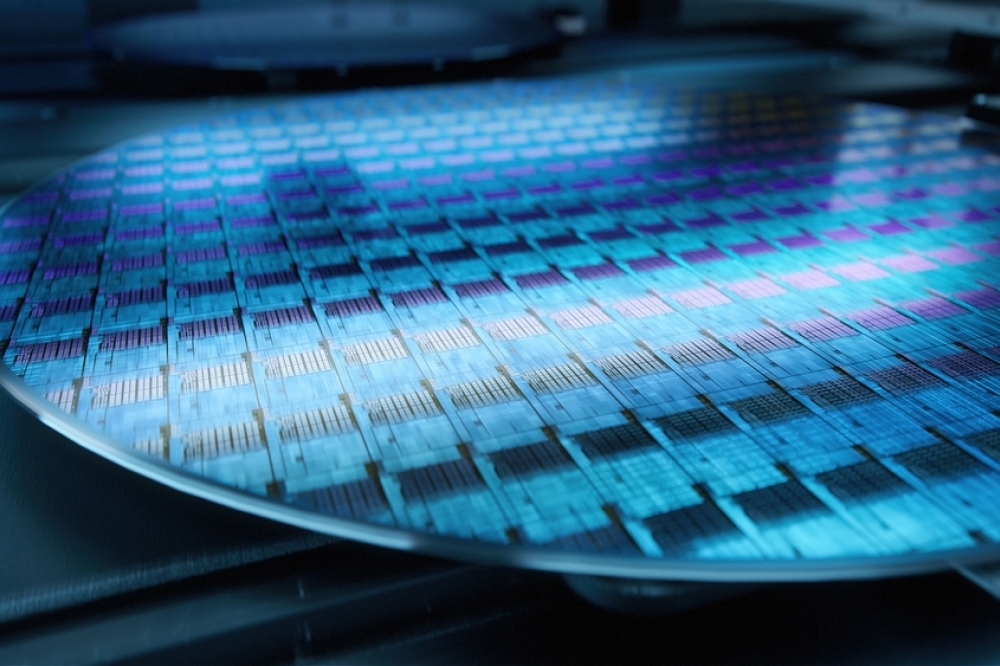

Greene Tweed devoted two years of design development and in-house testing in an attempt to lead the industry in not only friction reduction but also sealing in the most challenging low temperature applications. Benchmark testing against some of the top performing spring energized seals highlighted the compromise in performance at extreme temperatures. Low friction at higher temperatures resulted in high leakage at low temperatures. Prioritizing leakage control at low temperature resulted in higher friction. Greene Tweed’s new canted coil demonstrated a friction improvement of up to 61% across a wide temperature range while improving leakage control up to 74% especially at lower temperatures. All of this makes the new Canted Coil MSE ideal for a variety of smaller diameter applications, including precise robotic movement, precise valve controls, hydraulic actuation, medical dispensing, and semiconductor production.

Another benefit to the Canted Coil design is even as the sealing material wears away, the sealing and friction performance remains consistent.