PulseForge and NADAtech join forces

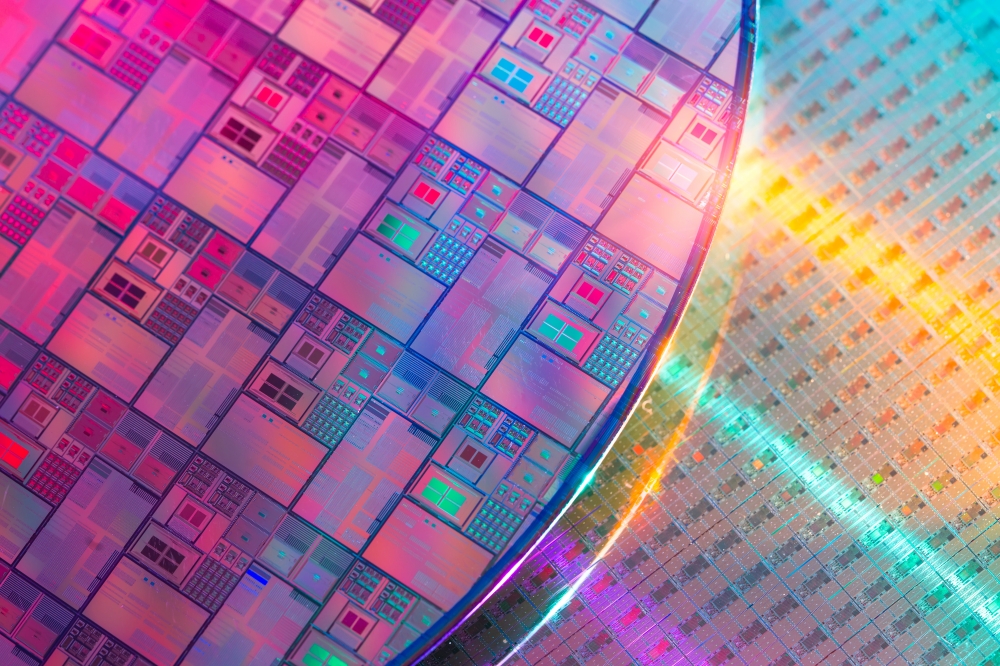

PulseForge and NADA Technologies are collaborating to bring a high-volume, fully-automated solution for debonding to the semiconductor industry.

This collaboration brings together two innovative US companies in the semiconductor space. NADAtech is the global leader in tailored wafer automation solutions for semiconductor manufacturing and PulseForge is an industry leader in applied thermal energy.

We are so excited to partner with PulseForge and bring this new technology to market. There is significant interest in this new debonding platform from customers and we will begin shipments in 2024.

NADAtech is known for engineering dual and triple functionality into their automation solutions for increased capacity and yield while minimizing their equipment footprint. The integration of PulseForge’s patented Photonic Debonding process introduces a new capability to NADAtech’s product line. The combined offering will significantly reduce the total cost of ownership versus traditional debonding methods while improving yields.

The NADAtech fully automated photonic debonding solution will be ideal for wafer thinning, hybrid bonding and micro-LED transfer applications. In addition, the solution can debond warped wafers without expensive warpage adjustment hardware or process changes, and provides a clean, ash-free process.

“It is great to be working closely with another US innovator in the semiconductor space.” said Jonathan Gibson, CEO of PulseForge, Inc. “This collaboration will provide customers with significantly lower costs for debonding processing while improving yields.”

“We are so excited to partner with PulseForge and bring this new technology to market. There is significant interest in this new debonding platform from multiple customers and we will begin shipments in 2024. Our collaboration will open new backend markets to NADAtech while offering greater efficiency to our customers.” said Tim Ewald, CEO/CTO of NADAtech.