ClassOne Technology secures Menlo Microsystems' order

Fast-growing microelectronics company to use industry-leading Solstice system for both electroplating and surface preparation in manufacturing of its Ideal Switch.

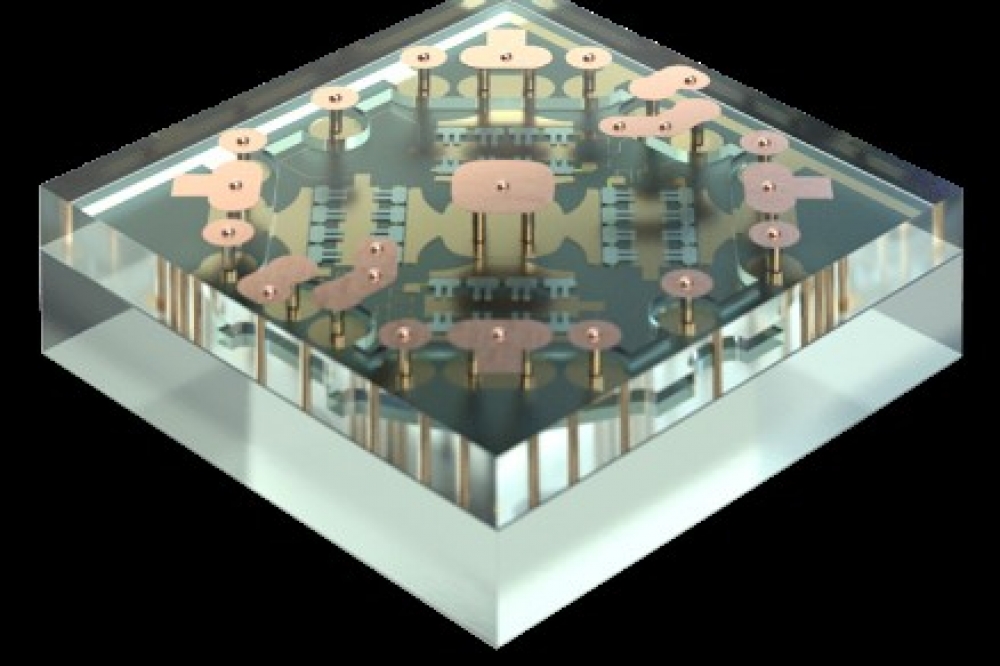

ClassOne Technology has secured an order for its Solstice® S8 single-wafer processing system from award-winning Menlo Microsystems (Irvine, Calif.). The ClassOne system will ship in mid-winter to Menlo Microsystems’ new facility in the Village of Lansing, New York, where it will be used for high-volume manufacture of the company’s Ideal Switch®.

Menlo Microsystems’ Ideal Switch technology combines the benefits of electromechanical and solid-state switches to create best-of-both-worlds solutions that enable 99-percent reductions in switch size, weight, power, and cost. Industries that benefit from Menlo Microsystem’ Ideal Switch include aerospace and defense, telecommunications, medical, industrial IoT, and test and measurement.

“With the launch of our new Ideal Fab™, we are primed to onshore our technology and shift production of our Ideal Switch® into high gear,” said Russ Garcia, CEO, Menlo Microsystems. “The Solstice S8 will help us to achieve our manufacturing goals. We are appreciative of the ClassOne team for their expertise and collaboration on process and tool configuration to help meet our exacting manufacturing requirements.”

Built on ClassOne’s state-of-the-art, high-throughput Solstice platform, the versatile Solstice S8 can perform a host of electroplating and surface preparation processes on a single system. Suitable for R&D as well as high-volume manufacturing, Solstice’s flexible design allows users to create a customized turnkey solution by mixing and matching the processes Menlo Microsystems requires for their patented Ideal Switch manufacturing process.

ClassOne Technology CEO Byron Exarcos stated, “We are thrilled to have the opportunity to work with a true innovator like Menlo Microsystems, which has completely reimagined switching technology. Collaborating with this exciting technology company expands our diverse customer base while further validating our industry-leading position in technologies like RF for 5G and IoT, semiconductors and compound semiconductors.”