EtherCAT Semiconductor Technical Working Group publishes further standards

The aim of the EtherCAT Technology Group Working Group, founded in 2011, is to develop EtherCAT standards for the semiconductor industry.

While the basic technology - i.e., the "how" of communication - naturally remains unchanged, the device profiles define the "what" for industry-specific devices such as mass flow controllers, high-vacuum pumps, plasma and high-frequency generators. To this end, the Working Group meets twice a year for meetings which last several days. The meetings, which have alternated between Silicon Valley in California and online since the pandemic, are regularly attended by 50-80 experts. These include both suppliers of devices and manufacturers of semiconductor production equipment. Their customers - the chip manufacturers - also attend consistently. The working group thus covers the entire supply chain and ensures that the specifications developed meet the requirements of both suppliers and their customers.

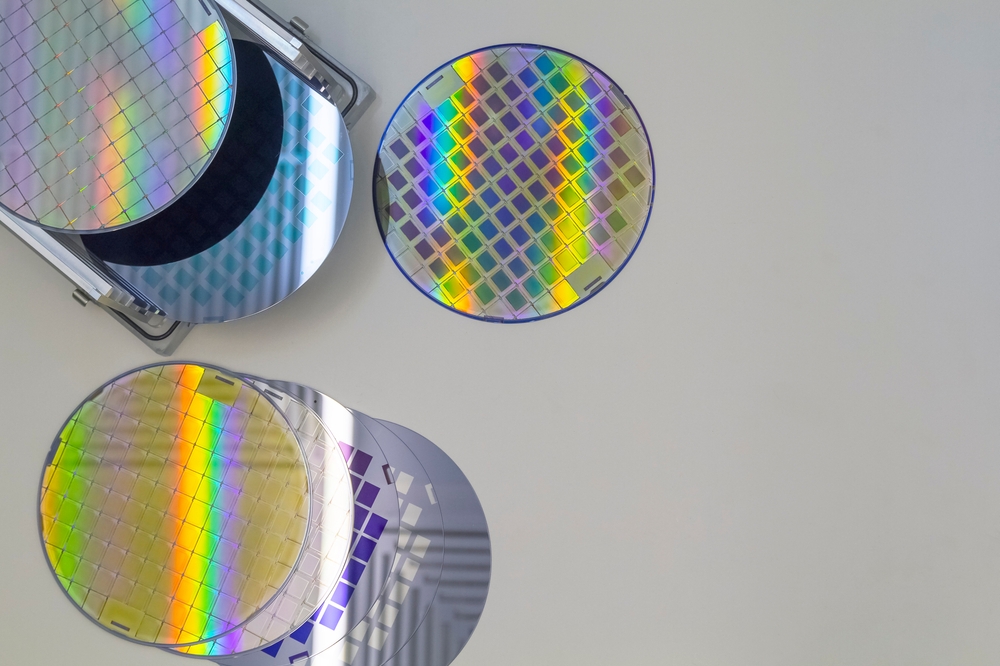

At the 24th meeting, which was held recently, four further profile specifications were approved, successfully concluding the work of the corresponding task groups: a variety of profiles for liquid flow controllers, for temperature sensors for wafer processing chambers, for sensors for voltage and current frequency analysis and for special process control valves. A further task group with the aim of developing the device profile for optical emission spectroscopy (OES) was also launched at this meeting. This profile will really benefit from the EtherCAT protocol's efficient utilization of bandwidth: up to 500 bytes of cyclical raw data must be transmitted to the controller per communication cycle. The series of special EtherCAT device profiles for the semiconductor industry has thus grown to a total of 24 specifications.

The experts will meet again in person at the 25th anniversary meeting in Silicon Valley in May 2024, where the working group will be hosted by two industry giants, Applied Materials and LAM Research. Regular face-to-face contact helps to maintain and build the trust and cooperation that has characterized TWG Semi over many years.