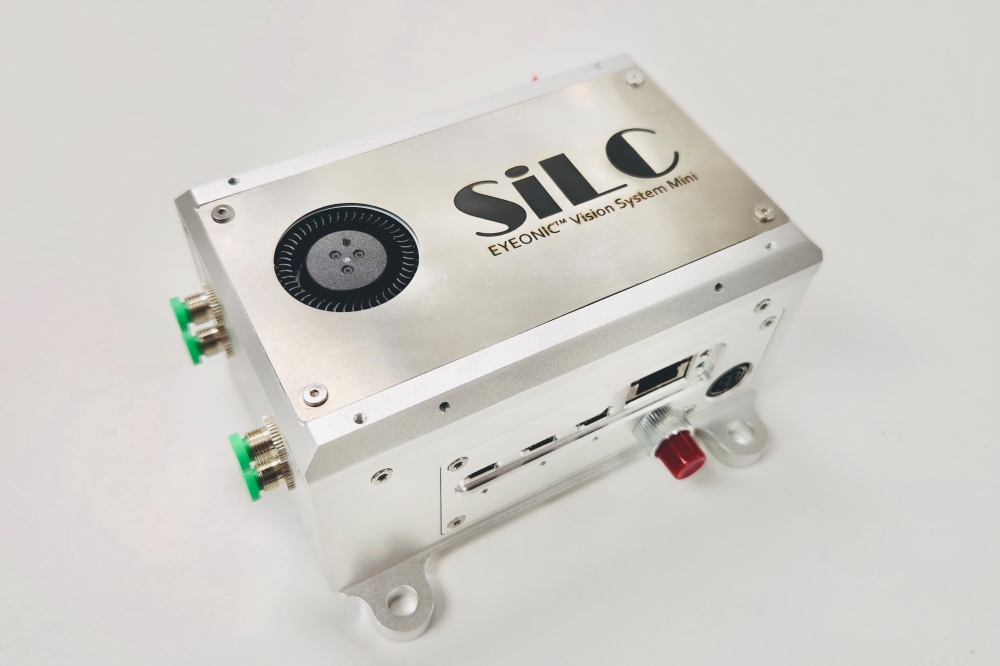

SiLC Technologies unveils Eyeonic Vision System Mini

A leap in precision LiDAR technology, the Eyeonic Mini offers 'unmatched' sub-millimeter resolution in a significantly reduced size.

The Eyeonic Mini is targeted to machine vision applications that require short-range vision detection with the highest levels of precision including robotics, warehouse logistics, industrial automation and more.

SiLC Technologies has launched the Eyeonic™ Vision System Mini (Eyeonic Mini), a groundbreaking advancement in LiDAR technology. This innovative system, integrating a full multi-channel FMCW LiDAR on a single silicon photonics chip and an integrated FMCW LiDAR System-on-Chip (SoC), is said to set a new industry benchmark in precision.

Utilizing the purpose-built digital LiDAR processor SoC, the iND83301 (“Surya”) developed by indie Semiconductor, the Eyeonic Mini achieves an 'unprecedented' level of detail, delivering an order of magnitude greater precision than existing technologies while being one-third the size of last year's model. This latest innovation builds upon the success of SiLC’s first commercial FMCW LiDAR system, the Eyeonic Vision System, founded on an integrated silicon photonics chip and designed specifically for machine vision applications.

SiLC’s Eyeonic Vision Chip, central to the system, amalgamates all essential photonics functions into a coherent vision sensor, delivering a compact solution that meets the demands for performance, affordability and low-power consumption. The system’s accuracy is driven by a 4-channel FMCW LiDAR chip, complemented by indie’s innovative Surya SoC, and equips robots with sub-millimeter depth precision from distances exceeding 10 meters.

This level of precision opens new doors in automation, particularly in warehouse logistics and AI machine vision applications. For instance, AI-driven palletizing robots equipped with the Eyeonic Mini can fully view and interact with pallets, optimizing package placement and loading onto trucks with efficiency and safety. In the context of the U.S., with its over 13 million commercial trucks, this technology promises to revolutionize warehouse operations and the broader trucking industry, significantly boosting efficiency in loading and unloading processes.

Giving robots the intelligence to see, move, touch, think and learn, Dexterity is working on incorporating SiLC technology into their robot autonomy platform. “At Dexterity, we focus on AI, machine learning and robotic intelligence to make warehouses more productive, efficient and safe,” remarked CEO Samir Menon. "We are excited to partner with SiLC to unlock LiDAR for the robotics and logistics markets. Their technology is a revolution in depth sensing and will enable easier and faster adoption of warehouse automation and robotic truck load and unload."

“Our FMCW LiDAR platform aims to enable a highly versatile and scalable platform to address the needs of many applications,” added Dr. Mehdi Asghari, CEO of SiLC Technologies. “At CES this year, we’re demonstrating our long-range vision capabilities of over two kilometers. With the Eyeonic Mini we’re showcasing our high precision at shorter distances. Our FMCW LiDAR solutions, at short or long distances, bring superior vision to machines to truly enable the next generation of AI-based automation.”

“The Eyeonic Mini represents the next evolution of our close collaboration with SiLC. The combination of our two unique technologies has created an industry-leading solution in performance, size, cost, and power,” said Chet Babla, SVP Strategic Marketing at indie Semiconductor. “This creates a strong foundation for our partnership to grow and address multiple markets, including industrial automation and automotive.”

For machines to be capable of truly augmenting our lives, their vision solution must be powerful, compact, scalable, and unaffected by complex, unpredictable environments and conditions, including interference from other systems. It must provide motion, velocity, polarization, and precision - prerequisites which exclude existing, time-of-flight-based solutions and instead point to FMCW as the needed platform. FMCW technology enables a new generation of imaging solutions that can directly capture images for AI machine vision, factory robots, home security, autonomous vehicles, and perimeter security