Greene Tweed introduces Fusion® F07

Performance-enhanced FKM for subfab exhaust lines.

Greene Tweed has introduced the Fusion® F07, a performance-enhanced fluoroelastomer. Developed by Greene Tweed material scientists and application engineers, Fusion® F07 is specifically crafted to withstand common Etch and CVD oxygen/fluorine based gases in semiconductor processing subfab lines, at temperatures up to 355°F (180°C).

With an expected lifetime of at least six months, Fusion® F07 lasts longer than standard FKM in subfab vacuum system lines. As a result, the new performance enhanced FKM extends the time between planned maintenance activities. Notably, it provides a better total cost of ownership where applications do not require an FFKM compound.

“At Greene Tweed, we enable customers to operate efficiently and safely in the world’s most demanding environments. We understand that the semiconductor industry needs reliability and longevity. Fusion® F07 is a result of meticulous research and development, aimed at not only extending the life of their system but also improve operational efficiency,” says Magen Buterbaugh, President and CEO, Greene Tweed.

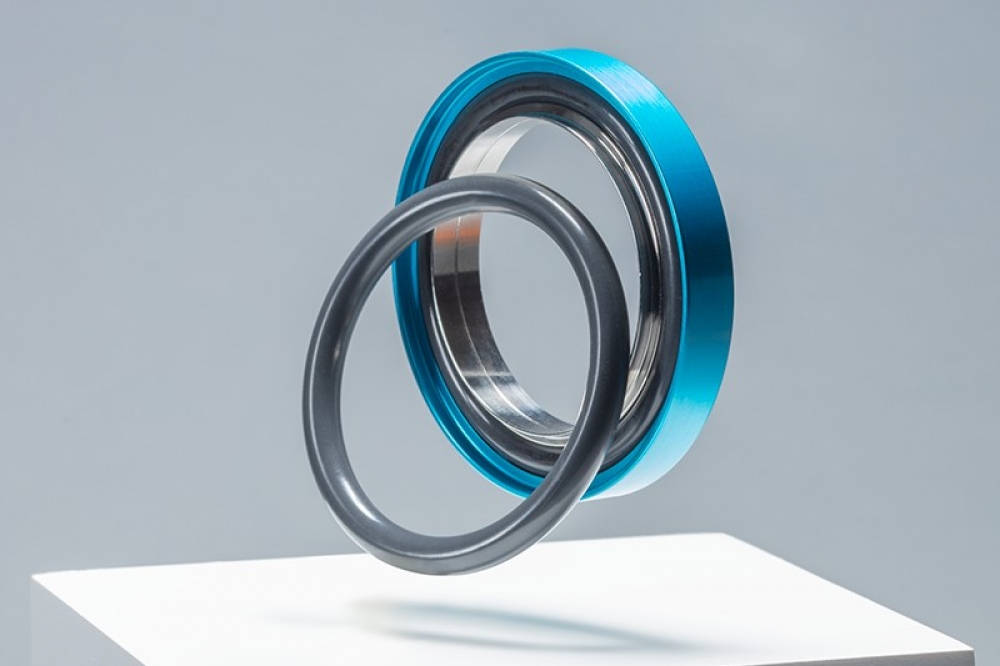

Fusion® F07 can be purchased as a seal assembly or as an individual O-Ring. Customers can effortlessly upgrade to Fusion® F07 and experience the benefits of extended lifetime and the resultant reduced operating costs as the seals are form-fit replaceable with other industry standard (KF/ISO flange fittings) seals. A blue outer ring allows for easier identification upon installation and replacement. Fusion® F07 seals are available in most typical sizes, including KF16, KF25, KF40, KF50, ISO63, ISO80, ISO100, ISO160, and ISO200.

As a leading global provider of sealing solutions to the semiconductor industry for over four decades, Greene Tweed engineers advanced elastomer seals and thermoplastic components that are found in a broad range of mission-critical equipment in key process areas of the world’s semiconductor fabs, including etch, deposition, aqueous, and electro-chemical (electroplating). The company is now investing in Korea with its upcoming state-of-the-art manufacturing facility expected to commence production this year. “Greene Tweed has a history of investing to meet the demands of our global customers and the Korea expansion offers the organization an opportunity to support the continued growth of the semiconductor industry in the region. The multi-million-dollar investment represents a significant increase in the company’s global manufacturing capacity while enabling supply chain resiliency,” said Magen Buterbaugh.