Intel launches Systems Foundry designed for the AI era

Intel announces expanded process roadmap, customers and ecosystem partners to deliver on ambition to be the No. 2 foundry by 2030.

Intel has launched Intel Foundry as a more sustainable systems foundry business designed for the AI era and announced an expanded process roadmap designed to establish leadership into the latter part of this decade. The company also highlighted customer momentum and support from ecosystem partners – including Synopsys, Cadence, Siemens and Ansys – who outlined their readiness to accelerate Intel Foundry customers’ chip designs with tools, design flows and IP portfolios validated for Intel’s advanced packaging and Intel 18A process technologies.

The announcements were made at Intel’s first foundry event, Intel Foundry Direct Connect, where the company gathered customers, ecosystem companies and leaders from across the industry. Among the participants and speakers were U.S. Secretary of Commerce Gina Raimondo, Arm CEO Rene Haas, Microsoft CEO Satya Nadella, OpenAI CEO Sam Altman and others.

An Intel factory employee holds a wafer with 3D stacked Foveros technology at an Intel fab in Hillsboro, Oregon, in December 2023. In February 2024, Intel Corporation launched Intel Foundry as the world’s first systems foundry for the AI era, delivering leadership in technology, resiliency and sustainability. (Credit: Intel Corporation)

“AI is profoundly transforming the world and how we think about technology and the silicon that powers it,” said Intel CEO Pat Gelsinger. “This is creating an unprecedented opportunity for the world’s most innovative chip designers and for Intel Foundry, the world’s first systems foundry for the AI era. Together, we can create new markets and revolutionize how the world uses technology to improve people’s lives.”

Process Roadmap Expands Beyond 5N4Y

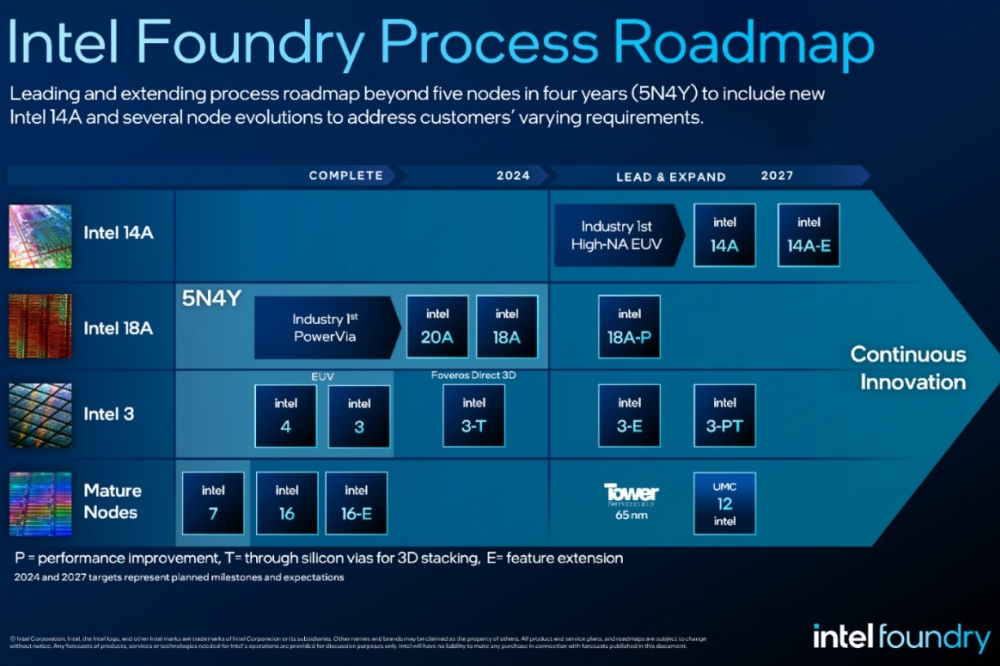

Intel’s extended process technology roadmap adds Intel 14A to the company’s leading-edge node plan, in addition to several specialized node evolutions. Intel also affirmed that its ambitious five-nodes-in-four-years (5N4Y) process roadmap remains on track and will deliver the industry’s first backside power solution. Company leaders expect Intel will regain process leadership with Intel 18A in 2025.

The new roadmap includes evolutions for Intel 3, Intel 18A and Intel 14A process technologies. It includes Intel 3-T, which is optimized with through-silicon vias for 3D advanced packaging designs and will soon reach manufacturing readiness. Also highlighted are mature process nodes, including new 12 nanometer nodes expected through the joint development with UMC announced last month. These evolutions are designed to enable customers to develop and deliver products tailored to their specific needs. Intel Foundry plans a new node every two years and node evolutions along the way, giving customers a path to continuously evolve their offerings on Intel’s leading process technology.

Intel also announced the addition of Intel Foundry FCBGA 2D+ to its comprehensive suite of ASAT offerings, which already include FCBGA 2D, EMIB, Foveros and Foveros Direct.

Microsoft Design on Intel 18A Headlines Customer Momentum

Customers are supporting Intel’s long-term systems foundry approach. During Pat Gelsinger’s keynote, Microsoft Chairman and CEO Satya Nadella stated that Microsoft has chosen a chip design it plans to produce on the Intel 18A process.

“We are in the midst of a very exciting platform shift that will fundamentally transform productivity for every individual organization and the entire industry,” Nadella said. “To achieve this vision, we need a reliable supply of the most advanced, high-performance and high-quality semiconductors. That’s why we are so excited to work with Intel Foundry, and why we have chosen a chip design that we plan to produce on Intel 18A process.”

Intel Foundry has design wins across foundry process generations, including Intel 18A, Intel 16 and Intel 3, along with significant customer volume on Intel Foundry ASAT capabilities, including advanced packaging.

In total, across wafer and advanced packaging, Intel Foundry’s expected lifetime deal value is greater than $15 billion.

IP and EDA Vendors Declare Readiness for Intel Process and Packaging Designs

Intellectual property and electronic design automation (EDA) partners Synopsys, Cadence, Siemens, Ansys, Lorentz and Keysight disclosed tool qualification and IP readiness to enable foundry customers to accelerate advanced chip designs on Intel 18A, which offers the foundry industry’s first backside power solution. These companies also affirmed EDA and IP enablement across Intel node families.

At the same time, several vendors announced plans to collaborate on assembly technology and design flows for Intel’s embedded multi-die interconnect bridge (EMIB) 2.5D packaging technology. These EDA solutions will ensure faster development and delivery of advanced packaging solutions for foundry customers.

Intel also unveiled an "Emerging Business Initiative" that showcases a collaboration with Arm to provide cutting-edge foundry services for Arm-based system-on-chips (SoCs). This initiative presents an important opportunity for Arm and Intel to support startups in developing Arm-based technology and offering essential IP, manufacturing support and financial assistance to foster innovation and growth.

Systems Approach Differentiates Intel Foundry in the AI Era

Intel’s systems foundry approach offers full-stack optimization from the factory network to software. Intel and its ecosystem empower customers to innovate across the entire system through continuous technology improvements, reference designs and new standards.

Stuart Pann, senior vice president of Intel Foundry at Intel said, “We are offering a world-class foundry, delivered from a resilient, more sustainable and secure source of supply, and complemented by unparalleled systems of chips capabilities. Bringing these strengths together gives customers everything they need to engineer and deliver solutions for the most demanding applications.”

Global, Resilient, More Sustainable and Trusted Systems Foundry

Resilient supply chains must also be increasingly sustainable, and today Intel shared its goal of becoming the industry’s most sustainable foundry. In 2023, preliminary estimates show that Intel used 99% renewable electricity in its factories worldwide. Today, the company redoubled its commitment to achieving 100% renewable electricity worldwide, net-positive water and zero waste to landfills by 2030. Intel also reinforced its commitment to net-zero Scope 1 and Scope 2 GHG emissions by 2040 and net-zero upstream Scope 3 emissions by 2050.