scia System receives NIST order

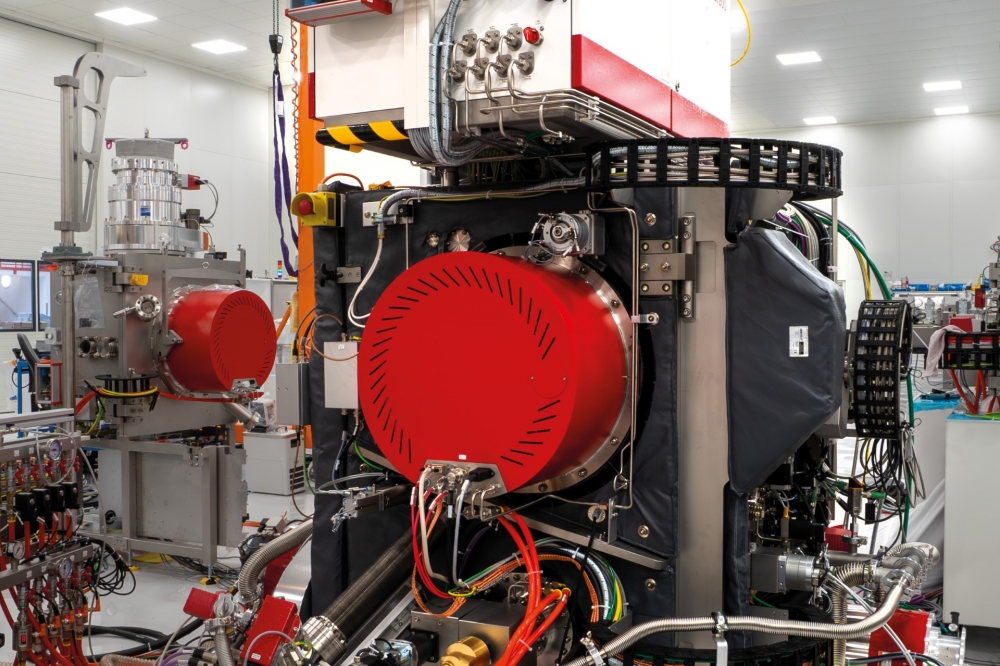

The scia Coat 200 system provides excellent uniformity for coating and etching processes using ion beam sputter deposition (IBSD) and ion beam etching (IBE).

The National Institute of Standards and Technology (NIST), one of the longest established physical science laboratories in the U.S., has purchased a scia Coat 200 system from scia Systems.

The customer will install the new scia Coat 200 in its Boulder Microfabrication Facility (BMF), a class 100 microelectronics processing facility. The state-of-the-art research laboratory supports the most sensitive research done at NIST to fabricate its next-generation microelectronic and microelectromechanical devices. The BMF will use the scia Coat 200 to deposit metals and dielectric materials as well as for the structuring of sensors and other devices.

High-Quality Multilayer Deposition with scia Coat 200

The scia Coat 200 uses ion beam sputtering (IBS) to achieve smooth, defect-free thin-film deposition. The IBS technology provides excellent uniformity for any coating by substrate rotation and tilt on up to 200 mm substrates. The system is equipped with a second ion beam source, used as an assist source, making the system capable of homogenous full surface ion beam etching. In-situ process control analysis ensures excellent process stability. The system enables the handling of wafers as well as arbitrarily shaped substrates.

A milestone for scia Systems

Although more than 500 advanced ion beam technologies of scia Systems have already been sold worldwide to industrial manufacturing and research institutes, this order marks a significant milestone for scia Systems and its local sales partner AARD Technology, LLC, because it is the first ion beam system sold to NIST. “We are pleased to have the opportunity to work with the BMF on their first installation and to support them to accelerate their path to production for their next-generation microelectronic and MEMS devices,” stated Dr. Michael Zeuner, CEO of scia Systems.