US DoD selects Intel Foundry for Phase Three of RAMP-C

Defence customers can now manufacture product prototypes on Intel 18A process technology.

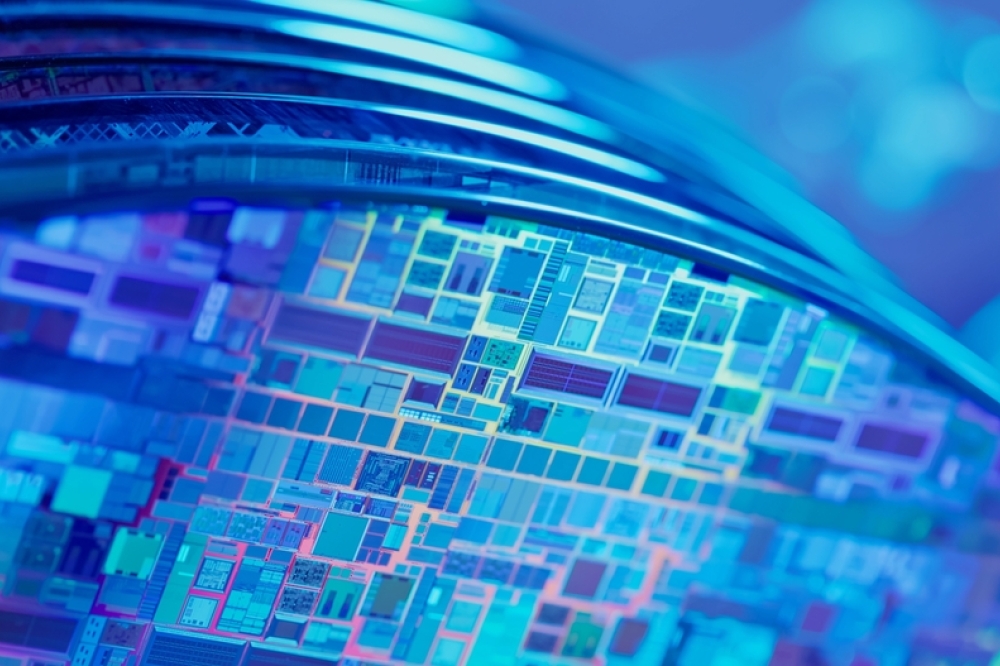

The U.S. Department of Defense (DoD) has awarded Intel Foundry Phase Three of its Rapid Assured Microelectronics Prototypes - Commercial (RAMP-C) program. The award was announced through the National Security Technology Accelerator’s (NSTXL) consortium-based Strategic and Spectrum Missions Advanced Resilient Trusted Systems Other Transaction Authority (S2MARTS OTA) program. The third phase of RAMP-C advances the tape-out and testing of early defense industrial base (DIB) product prototypes, signifying a critical milestone for the program that highlights the readiness of Intel 18A process technology, intellectual property (IP) and ecosystem solutions for high-volume manufacturing (HVM).

As part of the announcement, RAMP-C customers can begin manufacturing commercial and DIB product prototypes on Intel 18A process technology.

“Today marks another significant moment in advancing our collaboration with DoD on this program. We are very excited that for the first time in decades, U.S. government and defense industrial base customers will have access to one of the industry’s leading-edge process technologies at the same time as commercial customers. This milestone reinforces our commitment to making our capabilities, including leading-edge technologies like Intel 18A, available to a wider range of partners, furthering America’s leadership in process technology R&D, advanced manufacturing and microelectronics systems,” said Kapil Wadhera, Intel vice president for Foundry Services and general manager of the Government Engagements and Business Operations Group.

The RAMP-C program aims to restore domestic leadership in leading-edge semiconductors by incentivizing the creation of a sustainable, resilient and trusted commercial foundry ecosystem in the United States. The program enables U.S.-based DIB and commercial customers to fabricate leading-edge custom integrated circuits required for critical DoD systems and commercial products.

In 2021, Intel was selected to lead the first phase of RAMP-C, which laid the groundwork for Intel’s foundry business by establishing the technology and yield plans, developing IP and ecosystem tools, and preparing customers for test chip tape-outs. Phase Two expanded RAMP-C customers by onboarding Boeing and Northrop Grumman to design, develop and tape-out solutions based on Intel 18A while continuing to ramp the IP and ecosystem solutions. Phase three will open the stage of extensive test chips and multiple commercial and DIB product prototype tape-outs based on Intel 18A and using new IP and ecosystem tools.

“RAMP-C is an important project for Office of the Undersecretary of Defense for Research and Engineering Microelectronics as it provides access to leading-edge Intel 18A technology onshore, which is critical for the security of U.S. military systems and platforms. Intel Foundry, a performer on the RAMP-C project, has met their milestones and metrics for Phase Two of the project and has recently been awarded funding to start their Phase Three effort. R&E’s program, managed through Navy Crane and executed through an OTA with NSTXL, is ensuring that the DoD stays at the cutting edge of microelectronics technologies while facilitating close collaboration between the defense industrial base and commercial companies. RAMP-C intends to demonstrate prototype production of Intel 18A chips in 2025 to deliver unprecedented processing performance for the DoD,” said Dr. Dev Shenoy, secretary of defense for Research and Engineering, principal director for Microelectronics.

Intel’s Role in RAMP-C

Under RAMP-C, Intel Foundry has collaborated with industry leaders, including Microsoft, Nvidia, IBM, Cadence, Synopsys, Boeing, Northrop Grumman and others, to support the commercial and U.S. government’s needs for designing and manufacturing integrated circuits by establishing and demonstrating a semiconductor IP ecosystem to develop and fabricate test chips on Intel 18A, the company's leading process technology. Intel Foundry also established a U.S. Military, Aerospace and Government (USMAG) Alliance comprising ecosystem partners across electronic design automation (EDA), IP and design service providers to work with DIB customers for delivering the functional and operational security required by USMAG applications with Intel foundry technology and offerings.