Wave Photonics launches QPICPAC Chip Packaging solution

Wave Photonics, a Cambridge-based deep tech start-up, has launched an 'easy-to-use' turnkey packaging solution for prototyping and R&D.

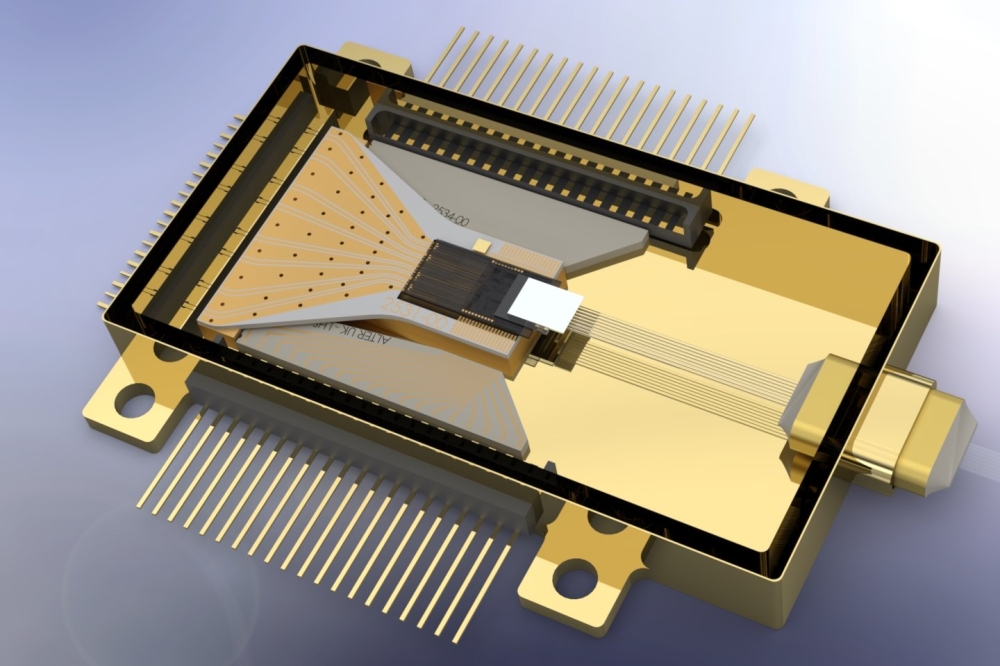

Wave Photonics, SENKO Advanced Components, a company producing high-quality optical components, and Alter Technology, who offer advanced packaging solutions, have worked together as part of an Innovate UK project referred to as Quantum Photonic Integrated Circuit PACkaging (QPICPAC), to produce packaging solutions for Quantum Photonic Integrated Circuits (QPICs).

The packaging solution, which includes design templates and components, can minimise custom development requirements and costs for quantum technology companies.

Jiangbo Zhu, Senior Photonics Engineer at Wave Photonics who led the photonics design work on the project said “We are thrilled to introduce our new packaging service for QPICs, which is specifically designed to meet the needs of quantum companies requiring rapid prototyping and dependable packaging. Our service is meticulously verified, ensuring streamlined processes and high reliability, all while maintaining cost efficiency. With this offering, we aim to accelerate innovation and support our customers in pushing the boundaries of quantum technology.”

Bernard Lee, Director of Technology and Innovation at SENKO Advanced Components, said, “SENKO is honoured to have been part of this project and has continued to actively invest in many quantum international standards and industrial bodies. We hope to continue to introduce the very best in leading edge optical interconnect technology for future quantum applications.”

Liam Moroney, Business Development Manager – Photonics (Alter Technology, UK) said “This represents a (quantum) leap towards the much-needed standardised approach to affordable complex photonic integrated circuit (PIC) based product realisation. Demonstrated here is a full UK supply chain and workflow for an end-to-end PIC solution, beginning with manufacturing-compatible PIC design and layout guidance using process and assembly design kits (PDK, ADK), and finishing up with robust packaging and device characterisation available in low to high volumes with a quick turnaround”.