JST wins front-end cleaning order

Highly flexible platform delivers 'unprecedented' flexibility, precision, and repeatability during the etching and deposition process.

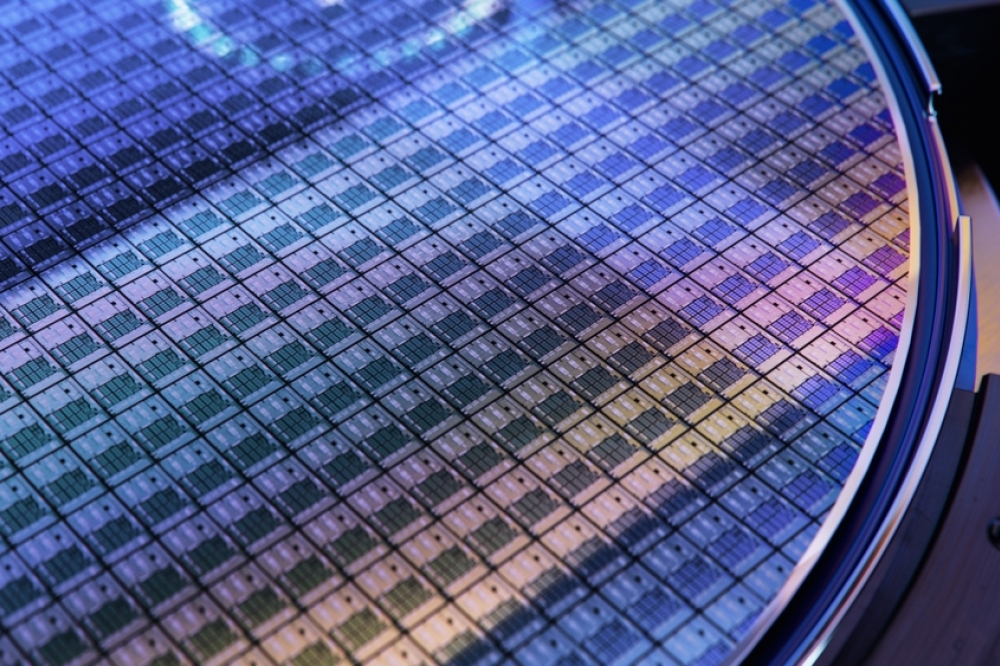

JST Manufacturing says that a global leader in the intelligent power and sensing technology markets selected JST’s 300mm multi-chamber Ospray Single Wafer Processing System for critical front-end cleaning applications. The system will ship in the second half of this year.

The single-wafer processing market continues to expand, with growth coming from the silicon and compound semiconductor markets. Industry research firm Mordor Intelligence estimates that the wafer cleaning equipment market size is US$9.10 billion in 2024, and is expected to reach US$13.57 billion by 2029, growing at a compound annual growth rate (CAGR) of 8.33% during the forecast period (2024-2029). Ospray single-wafer systems are well suited to support this growth, as they are designed to process complex substrates that require high-precision, high-uniformity surface preparation.

“The rapid acceleration of artificial intelligence, internet of things, 5G and other emerging technologies is increasing the need for advanced cleaning technologies to support manufacturing of smaller and more complex semiconductor devices,” said Ryan Zrno, CEO of JST. “This order showcases our ability to address wide-ranging customer requirements with our highly flexible Ospray platform. In qualification, the Ospray met our customer’s process requirements for substrate surface cleaning, etching and surface preparation, ensuring that wafers are free of organic contaminants, which is critical for subsequent processing steps.

The Ospray is an extremely flexible system that delivers superior uniformity and repeatability, which ranges from <1% to 3% depending on the process. The customer will use Ospray for front-end cleaning processes, and the configuration shipping includes a solvent process module for resist stripping.

“JST is seeing growth in single-wafer processing across both the silicon and compound semiconductor markets. Key target applications for Ospray include MEMS and sensors, optoelectronics, lasers, LEDs and photodiodes,” said Brian Thomas, director of sales for JST. “The system propels advanced surface cleaning like never before and allows for superior process capabilities and cost-effectiveness.”