EV Group highlights 3D integration process solutions at SEMICON Taiwan 2024

Presentations to highlight breakthrough capabilities of EVG’s maskless lithography, hybrid bonding and IR laser release solutions for heterogeneous integration; EVG sees continued strong growth in region.

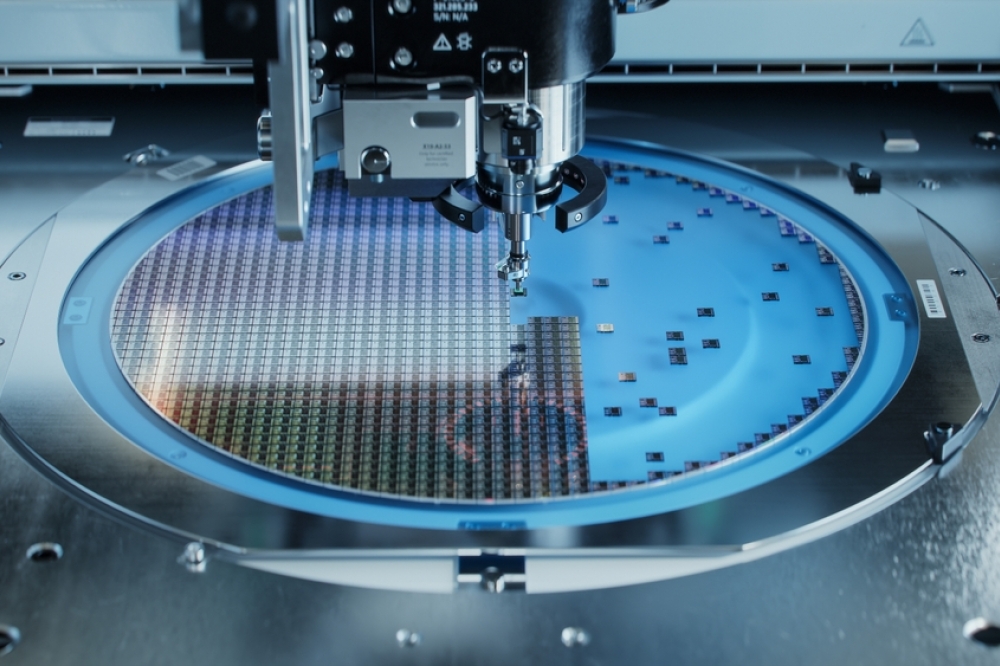

EV Group will highlight key advances in hybrid and fusion wafer bonding, infrared (IR) laser layer release technology, and lithography for advanced semiconductor and micro-electronics manufacturing and packaging at the SEMICON Taiwan 2024 expo in Taipei, Taiwan on September 4-6.

EVG’s innovative high-volume-manufacturing (HVM) ready process solutions and world-class engineering services and process expertise are enabling new ways to build semiconductors and support leading-edge semiconductor designs and chip integration schemes, such as high bandwidth memory (HBM), backside power distribution networks (BPDN), chiplets and much more.

SEMICON Taiwan, EVG speakers will present on the following topics:

“Maskless Patterning Solution for Multi-functional Chiplets in Advanced System-in-Package (SiP)” (TechXPOT – Wednesday, September 4, 2:00pm at Stage 4F, TaiNEX 1, Booth L1200)

Kuo Yin-Chuan, Process Technology Engineer at EV Group Taiwan Ltd., presents an overview of EVG’s LITHOSCALE® maskless exposure system and explains how LITHOSCALE overcomes the severe limitations of mask-based optical lithography systems in the development of next-generation advanced packaging technologies, such as inaccuracies from die placement and die shift variations caused by over-molding, and limited exposure areas in large-die interposer fabrication.

“Disruptive 3D Integration Technologies for Advanced Stacked Systems” (Heterogeneous Integration Global Summit – Friday, September 6, 2:25pm at Room 701GH, 7th Floor, TaiNEX 2)

Thomas Uhrmann, director of business development at EVG, presents an overview on the current industry trends and technological developments for both wafer-to-wafer and die-to-wafer hybrid bonding. Key technology differentiators and integration scenarios are discussed with respect to the hybrid bonding schemes in combination with IR laser-based carrier solutions, that enable disruptive device flows for ultra-thin 3D devices.

According to Dr. Thorsten Matthias, regional sales director Asia/Pacific at EV Group, “Taiwan is a crucial epicenter for the semiconductor industry, producing more than 60 percent of the world’s semiconductors, and about 90 percent of the most advanced-node devices. As such, it is important for EVG to have a strong presence at SEMICON Taiwan. Over the years, EVG has significantly expanded its presence in Taiwan to better meet the growing needs and challenges that our customers and partners in the region face. This year, we have taken additional steps for continued growth and long-term customer commitment in Taiwan in the years to come.”

EVG Sees Continued Growth in Taiwan

EVG continues to expand its local offices in Hsinchu, Taichung and Tainan, particularly in Taichung where EVG has added to its process and application engineering team as well as to its sales and service personnel. These growth activities serve to expand and strengthen EVG’s installation and support capabilities to its local HVM customers.

EVG’s wafer bonding and lithography products continue to do well in Taiwan, with the company’s LITHOSCALE maskless exposure lithography systems seeing particularly strong sales for supporting 3D-IC advanced packaging – a key application for LITHOSCALE. Additional strong sales in Taiwan have been seen in fusion and hybrid wafer bonding in 3D-IC advanced packaging.

This past April, EVG also hosted its Technology Day event in Hsinchu with the theme “AI, Edge Computing, Hyperconnectivity: Pioneering the Future of Semiconductor Innovation,” featuring presentations and talks from EVG, market analysts, and industry partners Applied Materials, ASMPT, and the Industrial Technology Research Institute (ITRI). This year’s EVG TechDay Tawain was among its most successful in the region to date, breaking a record high triple-digit attendance.