KoMiCo to establish Mesa cleaning and coating facility

Representing an over $50 million capital investment, the facility will create over 200 new jobs.

KoMiCo has signed a purchase agreement to develop a state-of-the-art facility for advanced semiconductor equipment parts cleaning, coating, and repair in Mesa, Arizona. Located in the Superstition Springs area of southeast Mesa, the facility is expected to be operational by 2026, creating over 200 new jobs.

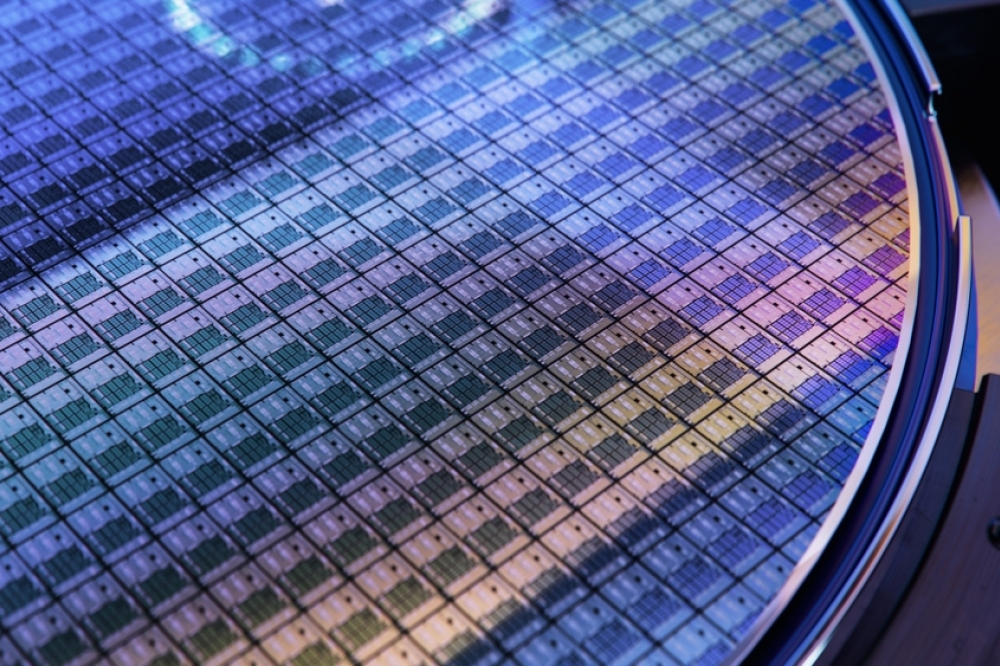

Fueled by major regional expansions from giants like Intel and TSMC, this facility will include multiple cleanrooms, a wide range of cutting edge equipment, and a robust suite of diagnostic tools. Representing an over $50 million capital investment, the Mesa facility will mark KoMiCo’s third location in the U.S. and eighth location globally. The 12.5 acre site and 125,000-square-foot building will be KoMiCo’s largest site in the U.S.

“KoMiCo is proud to partner with the City of Mesa in further establishing the Silicon Desert as the most technologically advanced semiconductor manufacturing region in the United States,” said Shawn Jang, CEO, KoMiCo U.S.

KoMiCo leads the industry with a dedicated R&D division and innovation driven by partnerships with their customers. This facility will be outfitted to provide services to current fabs and the fabs of the future, including EUV and <1nm tech nodes.

With sites in South Korea, Singapore, China, Taiwan and the U.S., KoMiCo is a strategic supplier to all of its customers, including the largest fab clusters in the world. The company excels in providing critical cleaning and coating services. KoMiCo employs a myriad of processes, each stringently controlled to meet or exceed customer specifications. Utilizing high-performance metrology equipment and particle measurement systems within clean-room environments, KoMiCo ensures that the cleaned parts are free from any form of impactful contamination. Their expertise in processing parts with fast turn-around times significantly reduces the downtime of fab tools.

“KoMiCo's new facility adds to Arizona’s dynamic semiconductor ecosystem and further emphasizes our state’s global significance for this critical industry,” said Sandra Watson, President and CEO of the Arizona Commerce Authority. “We are proud to welcome another world-renowned semiconductor supplier and are grateful to KoMiCo for its commitment to Arizona.”

“KoMiCo’s technology allowing for the service of the most advanced chips in the world helps Greater Phoenix continue to distinguish itself as a leader in the semiconductor ecosystem,” said Chris Camacho, President and CEO, Greater Phoenix Economic Council. “Innovation begets innovation, and we look forward to seeing how KoMiCo’s offerings will help other companies within the local supply chain grow.”

“I'm excited to welcome KoMiCo to Mesa, where they'll play a key role in the emerging semiconductor industry, ”said Mesa Mayor John Giles. "Their cutting-edge work in precision cleaning and coatings is exactly the kind of innovation that's driving our city's growth and helping to shape the future of technology. This investment is not just a win for Mesa, but for American manufacturing as we continue to build on the momentum created by the CHIPS and Science Act."

“I am excited to have KoMiCo bring well-paid jobs in advanced technology manufacturing to Mesa District 6,” said Scott Somers, City of Mesa District 6 Councilmember. “Bringing these jobs and processes to U.S. shores also strengthens our nation’s vital semiconductor supply chain.”

KoMiCo is a subsidiary of the MiCo group joined by MiCo Ceramics, MiCo Power, MiCo BioMed, and MiCo Ltd. MiCo Ltd also supports the semiconductor industry with raw material development, including special powders used in the coating process. In addition, MiCo Ceramics specializes in the manufacture of ceramic heaters and electrostatic chucks (ESC’s).